FreddyMar3

Well-Known Member

FreddieMar3, I am very interested in your plans. Question - what would make it capable of also doing 5 gallon batches? What would be different than the Brew Boss?

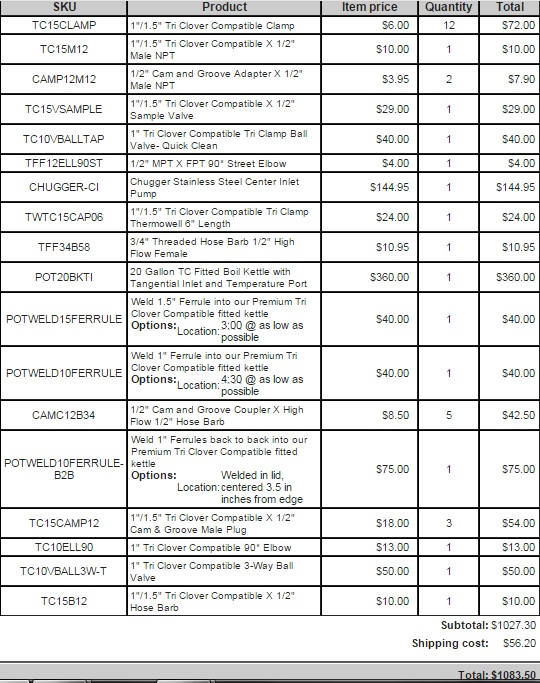

Two main differences:

-The 20 gallon kettle I bought has the same footprint as BB's 15 gallon kettle but is taller. This means that the mandatory dead space under the basket that is needed to clear the element is minimized. A 3.5 inch clearance in a 17.75in D kettle has more dead space than a 3.5 inch clearance in a 15.75in kettle. Does that make sense?

-Putting the recirc inlet in the lid allows me to get a mesh basket that will take up more of the space on the sides inside the kettle, lowering the grain height closer to the water level. I should have about .25-.35 inch clearance on all sides of the basket. The accessory port on the side of the BB kettle mandates that the basket is smaller so that it fits in.

I'm probably 2 months away from having the setup complete (parts backordered) and 4-5 months away from finishing my garage remodel, so it will be a while until I actually get to test it.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)