Almost a year of designing and fabrication I'm nearing completion of my electric 3 keggle plus HEX build.

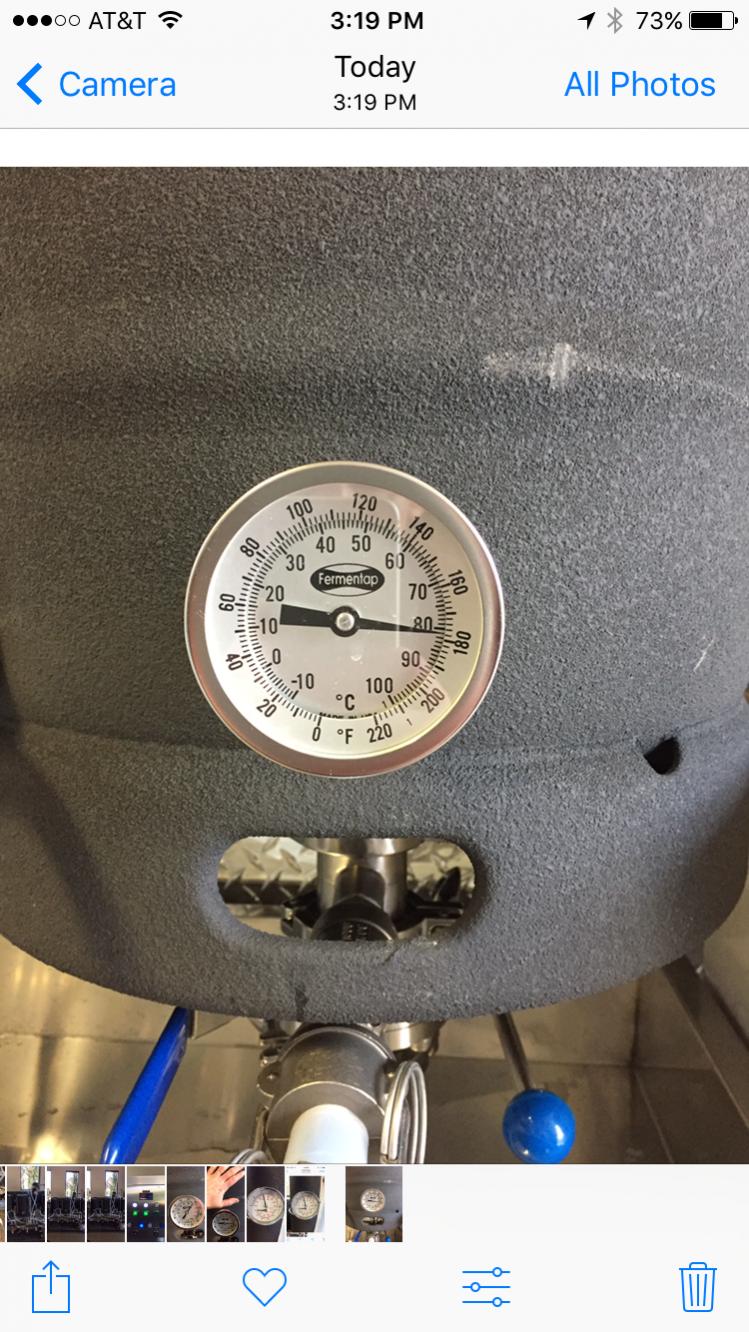

After grit blasting the keggles I had all my stainless sent out for passivation and am now applying a ceramic insulation coating to protect and hopefully insulate my keggles, HEX, and Manifolds.

Has anyone else applied an insulative coating to their kettles? The coating is supposed to reduce thermal transfer by 35*-40*F. At very least I hope it reduces potential accidental burns from rubbing up against a keggle.

I rather like the matte black finish.

Two more coats to go...

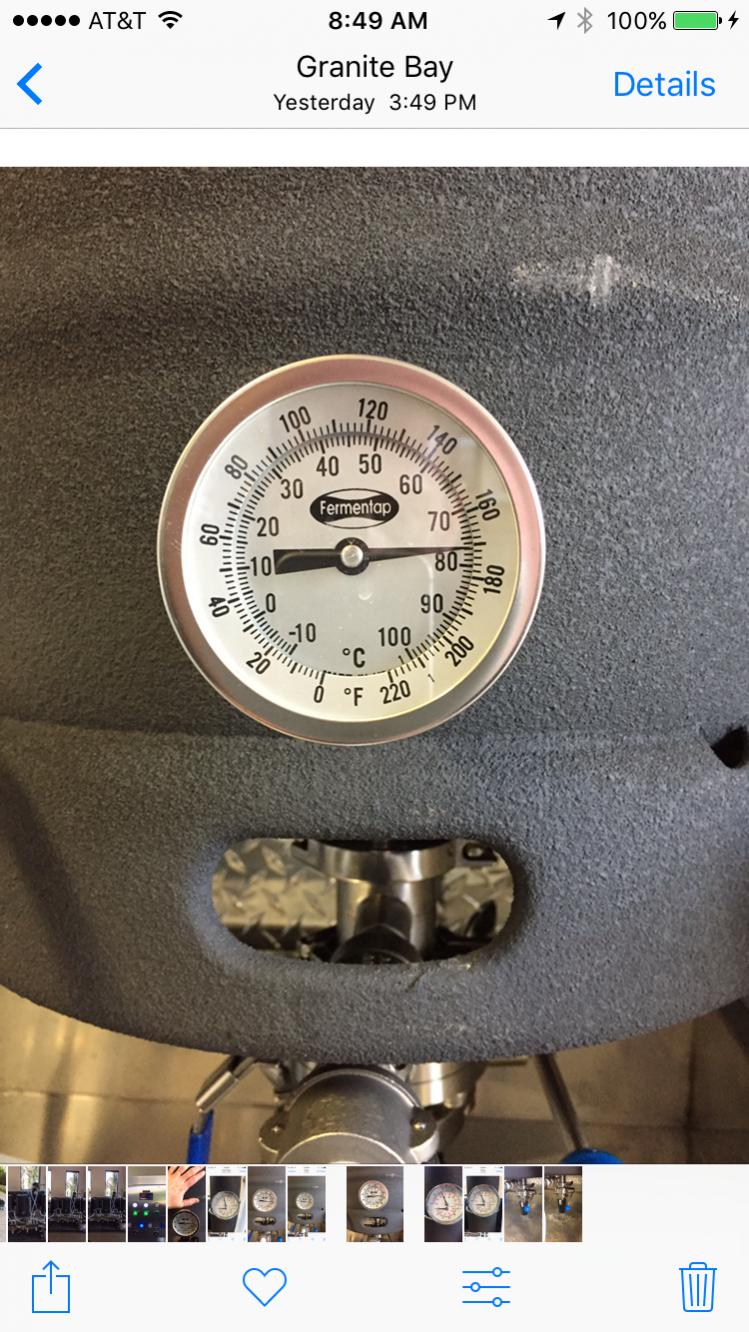

After grit blasting the keggles I had all my stainless sent out for passivation and am now applying a ceramic insulation coating to protect and hopefully insulate my keggles, HEX, and Manifolds.

Has anyone else applied an insulative coating to their kettles? The coating is supposed to reduce thermal transfer by 35*-40*F. At very least I hope it reduces potential accidental burns from rubbing up against a keggle.

I rather like the matte black finish.

Two more coats to go...