You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Blichmann Burner and Low Pressure Propane

- Thread starter ssgross

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Thanks for the updates. I was really hoping you were able to get your burners really going with the low pressure propane, so that I could copy your setup.

Sent from my BNTV600 using Home Brew mobile app

Yeah me too, currently things seem to be working a bit better. I was able to heat 20 gallons of water to 160 deg on two burners in an about an hour twenty minutes. My next idea is down sizing from bg14 burners to 8" jet burners.

Both burners going at the same time wide open.

I have the larger orifice installed in the burner on the right, while the smaller orifice is on the burner on the left. During my last brew I swapped out orifices on the right burner which seemed to give me the best rolling boil to date, that orifice was the one that more beer sells for low pressure.

In the photo the flame looks low, in reality it is much higher and produces a lot of heat. In my case and perhaps yours I'm using kegs, kegs are not very good at conducting heat, I'd bet a good triclad kettle would perform much better. Also I'm using 14.5 gallon German kegs, due to the narrow nature I end up heating the lower collar to the point of it glowing cherry red, obviously this is taking heat away from the bottom. I plan on using an American sanky keg as the BK on my next brew, the wider bottom should heat better with the big BG14 burner.

During my brew yesterday I boiled down from 12 to 10.5 gallons in an hour, really this is not too bad.

Back to my other thoughts of a split system, a high pressure burner under the BK would probably help a bunch. I've seen some production brew set ups that supply high pressure LP to a gas rail with a low pressure regulator taped off of the LP gas rail, seems like a good idea. BG14 burners can still be used, one with a high pressure orifice and the other with the low pressure orifice. The high pressure LP will be used for boiling and heating strike water faster then normal, while the low pressure burner can be used to maintain specific temps in the HLT with a HERMS Coil which will be used for maintaing correct mash temps.

ssgross

Well-Known Member

I finally got around to playing with the gas system and wanted to report my findings.

Most low pressure users in all the forums, including me, have made the mistake of using standard (1/4 id) hose somewhere in the build, after the low pressure regulator. This is like trying to fill a swimming pool with the hose that came with a pressure washer.

What I changed - working back from the burners:

#51 orifice to 5/8od supply line (from lowes, 48" with 1/2"npt connections for $30, came in a kit in the water heater section)

this connects to the honeywell outlet.

From the honeywell, 1/2" black iron pipe to the back of the rig - no change here.

low pressure regulator (see previous post) now mounted directly to the pipe, and not the tank.

The 10psi regulator and hose that came with the burner connects the tank to the rig.

In short, everything after the low pressure regulator should be large id. I use 1/2", even though the outlet on the low pressure regulator is 3/8".

The burners are now roaring like a champ. The sound is similar to when they were operated on high pressure. In fact, if I put the back of my hand by the damper, I can feel the draft of air being sucked into the venturi!

This also fixed the lazy pilot light. The burning propane at the burner has the effect of providing some suction, inducing greater flow of propane up the supply line, and through the honeywell regulator. This appears to have the effect of increasing the flow to the pilot light as well.

The flame on the burners are solid blue, but sometimes the tops flick yelllow. I'm not going to trouble with this since there is no soot on my pots. The boil pot burner took 10 gal of my well water, which is a constant 51.5F year round, to a roaring boil in 60 minutes. On brew day, 13.5gal went from 155 (temp when I lit the burner after sparge), to a roaring boil in a bit less than 20 minutes. :rockin:

i will post back some pics when I wheel it out next brew day (2 weeks, or the first day where the afternoon high peeks above freezing long enough to keep my water hose thawed).

Most low pressure users in all the forums, including me, have made the mistake of using standard (1/4 id) hose somewhere in the build, after the low pressure regulator. This is like trying to fill a swimming pool with the hose that came with a pressure washer.

What I changed - working back from the burners:

#51 orifice to 5/8od supply line (from lowes, 48" with 1/2"npt connections for $30, came in a kit in the water heater section)

this connects to the honeywell outlet.

From the honeywell, 1/2" black iron pipe to the back of the rig - no change here.

low pressure regulator (see previous post) now mounted directly to the pipe, and not the tank.

The 10psi regulator and hose that came with the burner connects the tank to the rig.

In short, everything after the low pressure regulator should be large id. I use 1/2", even though the outlet on the low pressure regulator is 3/8".

The burners are now roaring like a champ. The sound is similar to when they were operated on high pressure. In fact, if I put the back of my hand by the damper, I can feel the draft of air being sucked into the venturi!

This also fixed the lazy pilot light. The burning propane at the burner has the effect of providing some suction, inducing greater flow of propane up the supply line, and through the honeywell regulator. This appears to have the effect of increasing the flow to the pilot light as well.

The flame on the burners are solid blue, but sometimes the tops flick yelllow. I'm not going to trouble with this since there is no soot on my pots. The boil pot burner took 10 gal of my well water, which is a constant 51.5F year round, to a roaring boil in 60 minutes. On brew day, 13.5gal went from 155 (temp when I lit the burner after sparge), to a roaring boil in a bit less than 20 minutes. :rockin:

i will post back some pics when I wheel it out next brew day (2 weeks, or the first day where the afternoon high peeks above freezing long enough to keep my water hose thawed).

Wow thanks for the suggestions, the only difference between your setup an mine is the 5/8 hose to the # 51 orifice....going to lows at lunch for some parts.

The photo attached is my two stage regulator, the outlet is 1/2". All the gas plumbing on my system is 1/2" with the exception of the line between the burner orifice and burner shutoff valve.

The photo attached is my two stage regulator, the outlet is 1/2". All the gas plumbing on my system is 1/2" with the exception of the line between the burner orifice and burner shutoff valve.

ssgross

Well-Known Member

also, take a look at the chart I posted further (a link to plumbing supply). add up all the 1/2"id line after your low pressure regulator and you can calculate the max potential BTU you can deliver to your burner.

for example, in my setup there is 3 ft. black iron pipe, with the honeywell at the end, then 48" supply line up to the burner. The drop in the chart is approximately linear change at approx -950 btu per inch of line. also, make sure that the high pressure side is capable of delivering that btu to the low pressure regulator.

for example, in my setup there is 3 ft. black iron pipe, with the honeywell at the end, then 48" supply line up to the burner. The drop in the chart is approximately linear change at approx -950 btu per inch of line. also, make sure that the high pressure side is capable of delivering that btu to the low pressure regulator.

$33.95

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Bridgeview Beer and Wine Supply

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

also, take a look at the chart I posted further (a link to plumbing supply). add up all the 1/2"id line after your low pressure regulator and you can calculate the max potential BTU you can deliver to your burner.

for example, in my setup there is 3 ft. black iron pipe, with the honeywell at the end, then 48" supply line up to the burner. The drop in the chart is approximately linear change at approx -950 btu per inch of line. also, make sure that the high pressure side is capable of delivering that btu to the low pressure regulator.

The two stage regulator I have is rated at 200,000 BTU/hr.

I have from the regulator to the end of my gas rail I world say 6', this includes the hose from the regulator to the gas rail, from the honeywell valve to the burner is probably 48". I also have a second burner, which manually controlled, this burner is the closest to the regulator with a about 48-50" total of plumbing.

Now you really have me thinking, and in a good way too, I may do myself a favor by trimming down some plumbing.

ssgross

Well-Known Member

the 5/8 od supply line came in a 4 ft. lenghth. I didn't see any smaller lengths at lowes (accept for the 1/2 od (3/8 id), which wouldn't be as effective as per the chart above)

the 5/8 od supply line came in a 4 ft. lenghth. I didn't see any smaller lengths at lowes (accept for the 1/2 od (3/8 id), which wouldn't be as effective as per the chart above)

Yeah that's all I saw too, I have one coming off my regulator connecting it to the gas rail. My plans are to direct connect the regulator to the gas rail, this will remove 4' of plumbing from the low pressure side, I'll go with a 24-36" hose from the POL to the high pressure side if the two stage regulator. Next I'm going to try and shorten up the gas rail, make better use of the 4' flex LP line and do away with perhaps 12-24" of hard plumbing.

ssgross, thank you SO much for the help, while I'm not quite getting the results you are I'm moving in the right direction, this is what I've accomplished...

Adapted the orifice to accept 5/8" plumbing, however from the Honeywell valve to the burner is about 60" of plumbing, so really to get the most out if this system I need to shorten the LP supply lines.

I've mounted my regulator directly to the gas rail.

Currently the larger orifice seems to give me the highest flame, although with yellow tips, while the smaller orifice does not seem to do so well. I think with shorter LP lines I'll be able to use the smaller orifice and achieve the best BTU performance. The attached photo shows why I have such long gas lines, I wanted on/off valves as well as I needed the cross beams to mount the gas pipe to.

Adapted the orifice to accept 5/8" plumbing, however from the Honeywell valve to the burner is about 60" of plumbing, so really to get the most out if this system I need to shorten the LP supply lines.

I've mounted my regulator directly to the gas rail.

Currently the larger orifice seems to give me the highest flame, although with yellow tips, while the smaller orifice does not seem to do so well. I think with shorter LP lines I'll be able to use the smaller orifice and achieve the best BTU performance. The attached photo shows why I have such long gas lines, I wanted on/off valves as well as I needed the cross beams to mount the gas pipe to.

ssgross

Well-Known Member

Looking good. to answer a previous post, the blichmann burners have about 4 inches above the face of the burners to the kettle. I'm not entirely convinced that the #51 orifice is optimal for the Blichmann burner. I can confirm that it works. no soot, and about an hour to take 10 gal from 50f to boiling. i tried 3 other sizes, and like this one the best. The largest was the orifice valve from brewers hardware. it was satisfactory with the damper fully open and the valve only 1/4 open. This made the flames lazy, and no where near the same heat output.

Thanks again for the help, I'm defiantly going in the right direction, I feel that once I remove some plumbing the #51 orifice will work better for my system too. My regulator is at the end of the gas rail, I'm going to move it to the middle and shorten the piping runs to the burners, then I feel that the smaller orifice will do better. Again thanks for all the help, this is the first time I can say that I've made forward progress towards better heat output.

So I brewed this weekend, while I've not achieved the same results as the OP the performance of the burners is better, 12 gallons of 50 degree water to 150 in 45 min, not too bad.

I've made a decision, right or wrong, to ditch the BG-14 burners for 8" jet burners, I feel the BG 14 burner is way too big for the amount of LP I'm pushing. I can get a jet burner for about $30.00, hell with all the trips to lowes and the countless brass fittings to fit a 5/8 line to a 3/8 orifice I could have purchased two jet burners. Jet burners are designed for low pressure LP, really I don't think the banjo burners are.

I've made a decision, right or wrong, to ditch the BG-14 burners for 8" jet burners, I feel the BG 14 burner is way too big for the amount of LP I'm pushing. I can get a jet burner for about $30.00, hell with all the trips to lowes and the countless brass fittings to fit a 5/8 line to a 3/8 orifice I could have purchased two jet burners. Jet burners are designed for low pressure LP, really I don't think the banjo burners are.

According to tejas smokers they recommend a size 42 for the blichmann burner. I ordered one and asked them to drill it that way, but I don't think they drilled it out because the flame was very weak with the valve opened all the way. It actually would not boil 8.5 gallons whereas despite flame stability issues the supposedly smaller orifice from brewers hardware boiled with no problem. borrowing drills from one of my techs and I will try size 42 and report back.

ssgross

Well-Known Member

was their recommendation for low pressure or high pressure? Also, what size line do you have going to the burner?

ssgross, thank you SO much for the help, while I'm not quite getting the results you are I'm moving in the right direction, this is what I've accomplished...

Adapted the orifice to accept 5/8" plumbing, however from the Honeywell valve to the burner is about 60" of plumbing, so really to get the most out if this system I need to shorten the LP supply lines.

I've mounted my regulator directly to the gas rail.

Currently the larger orifice seems to give me the highest flame, although with yellow tips, while the smaller orifice does not seem to do so well. I think with shorter LP lines I'll be able to use the smaller orifice and achieve the best BTU performance. The attached photo shows why I have such long gas lines, I wanted on/off valves as well as I needed the cross beams to mount the gas pipe to. View attachment 177389

Herc - one other thing you could try is raising the height of your burners. I run my bg14's at 3.5" below flat bottom kettles.

was their recommendation for low pressure or high pressure? Also, what size line do you have going to the burner?

I have a 12 foot 3/8 id hose from a "Gas Plug" brand gas quick connect on my house running 11" water column propane (the pressure that runs normal household appliances.

The Texas smokers orifice wasn't drilled out as specified and I drilled it out, unfortunately I broke the valve and orifice when I reinstalled it. I made a eureka moment though.

Big yellow smoky flames mean that there is not enough air coming through the air shutter. While it was disassembled I realized that the air inlet under the damper is much bigger. I decided to try the burner without the damper installed with the Brewers hardware orifice, it runs very well. Wind produces a little yellow flame and sooting but it gets back under control pretty easily. I'll be adding a needle valve to the Brewers hardware orifice and can handle a little sooting.

Not sure no damper is the right long term solution. Will be bringing the damper into my shop to enlarge the openings.

pdxwarrior

Member

- Joined

- Feb 8, 2009

- Messages

- 6

- Reaction score

- 0

Hey, I'm not sure if any of the original posters are even members, but thought I'd ask the group. I'm in the process of building a new brewing setup and want to be able to run two burners off of one tank. In time, I'll eventually tie in some burner controllers, but for now it'll be manual still.

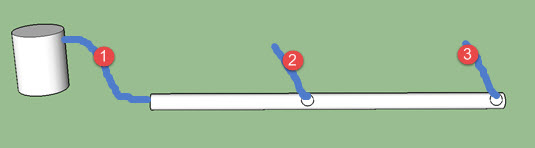

Anyway, I'm curious about gas management and making sure I get good gas/heat management. I've built a 1/2" manifold that is about 3.5 ft long. To describe, this the propane tank will connect to one end. About 18" down there is a T-connector where the first burner will connect. Down another 24" is a 90 degree turn that has another connection for the second burner.

The first burner will be a TopTier Blichmann burner. The second will be a Hellfire Blichmann burner.

Reading over this thread got me thinking about gas distribution. My original thought was to connect a hose (typical BBQ hose) from the propane tank to the end of the manifold, using a 3/8" flare connector. Then I would just use 3/8" hoses to go from the ports on the manifold to the burners. After reading, I am thinking this will not be efficient at all.

Then I figured I could get a larger more capable regulator (support 200,000BTU) and connect that to the manifold. That might work. However, then have concerns over how that gets distributed to the burners and if that's too much flow, etc.

So my current thought now is this. (Please refer to the attached image for more details)

View attachment 629151

Get an RV style hose that has the tool-less ACME connector on one end and a 1/4" male connector on the other end. Use this to connect the tank directly to the manifold (#1). There not be a regulator installed here. However, I have tested the manifold and it holds 14 PSI with no issues - so I think that'll be good. Next I can use adapters to convert the T-connectors from 1/2" down to 1/4" and attach 1/4" to Propane ACME adapters. That would allow me to then connect the original hoses (#2 and #3) from the Blichmann burners (using their regulators) directly to the manifold. This should regulate the pressures based on their regulators/specs.

In my mind, this makes sense. For the most part I would have 1/2" connections all the way up to the regulators (with the exception of a couple stepdowns for the 1/4" connectors. The hoses themselves are the standard 3/8" OD.

These might be dumb questions, but I'm new to the gas idea and BTU utilization, blah blah blah.

Thoughts?

Anyway, I'm curious about gas management and making sure I get good gas/heat management. I've built a 1/2" manifold that is about 3.5 ft long. To describe, this the propane tank will connect to one end. About 18" down there is a T-connector where the first burner will connect. Down another 24" is a 90 degree turn that has another connection for the second burner.

The first burner will be a TopTier Blichmann burner. The second will be a Hellfire Blichmann burner.

Reading over this thread got me thinking about gas distribution. My original thought was to connect a hose (typical BBQ hose) from the propane tank to the end of the manifold, using a 3/8" flare connector. Then I would just use 3/8" hoses to go from the ports on the manifold to the burners. After reading, I am thinking this will not be efficient at all.

Then I figured I could get a larger more capable regulator (support 200,000BTU) and connect that to the manifold. That might work. However, then have concerns over how that gets distributed to the burners and if that's too much flow, etc.

So my current thought now is this. (Please refer to the attached image for more details)

View attachment 629151

Get an RV style hose that has the tool-less ACME connector on one end and a 1/4" male connector on the other end. Use this to connect the tank directly to the manifold (#1). There not be a regulator installed here. However, I have tested the manifold and it holds 14 PSI with no issues - so I think that'll be good. Next I can use adapters to convert the T-connectors from 1/2" down to 1/4" and attach 1/4" to Propane ACME adapters. That would allow me to then connect the original hoses (#2 and #3) from the Blichmann burners (using their regulators) directly to the manifold. This should regulate the pressures based on their regulators/specs.

In my mind, this makes sense. For the most part I would have 1/2" connections all the way up to the regulators (with the exception of a couple stepdowns for the 1/4" connectors. The hoses themselves are the standard 3/8" OD.

These might be dumb questions, but I'm new to the gas idea and BTU utilization, blah blah blah.

Thoughts?

pdxwarrior

Member

- Joined

- Feb 8, 2009

- Messages

- 6

- Reaction score

- 0

Hey, I'm not sure if any of the original posters are even members, but thought I'd ask the group. I'm in the process of building a new brewing setup and want to be able to run two burners off of one tank. In time, I'll eventually tie in some burner controllers, but for now it'll be manual still.

Anyway, I'm curious about gas management and making sure I get good gas/heat management. I've built a 1/2" manifold that is about 3.5 ft long. To describe, this the propane tank will connect to one end. About 18" down there is a T-connector where the first burner will connect. Down another 24" is a 90 degree turn that has another connection for the second burner.

The first burner will be a TopTier Blichmann burner. The second will be a Hellfire Blichmann burner.

Reading over this thread got me thinking about gas distribution. My original thought was to connect a hose (typical BBQ hose) from the propane tank to the end of the manifold, using a 3/8" flare connector. Then I would just use 3/8" hoses to go from the ports on the manifold to the burners. After reading, I am thinking this will not be efficient at all.

Then I figured I could get a larger more capable regulator (support 200,000BTU) and connect that to the manifold. That might work. However, then have concerns over how that gets distributed to the burners and if that's too much flow, etc.

So my current thought now is this. (Please refer to the attached image for more details)

Get an RV style hose that has the tool-less ACME connector on one end and a 1/4" male connector on the other end. Use this to connect the tank directly to the manifold (#1). There not be a regulator installed here. However, I have tested the manifold and it holds 14 PSI with no issues - so I think that'll be good. Next I can use adapters to convert the T-connectors from 1/2" down to 1/4" and attach 1/4" to Propane ACME adapters. That would allow me to then connect the original hoses (#2 and #3) from the Blichmann burners (using their regulators) directly to the manifold. This should regulate the pressures based on their regulators/specs.

In my mind, this makes sense. For the most part I would have 1/2" connections all the way up to the regulators (with the exception of a couple stepdowns for the 1/4" connectors. The hoses themselves are the standard 3/8" OD.

These might be dumb questions, but I'm new to the gas idea and BTU utilization, blah blah blah.

Thoughts?

Anyway, I'm curious about gas management and making sure I get good gas/heat management. I've built a 1/2" manifold that is about 3.5 ft long. To describe, this the propane tank will connect to one end. About 18" down there is a T-connector where the first burner will connect. Down another 24" is a 90 degree turn that has another connection for the second burner.

The first burner will be a TopTier Blichmann burner. The second will be a Hellfire Blichmann burner.

Reading over this thread got me thinking about gas distribution. My original thought was to connect a hose (typical BBQ hose) from the propane tank to the end of the manifold, using a 3/8" flare connector. Then I would just use 3/8" hoses to go from the ports on the manifold to the burners. After reading, I am thinking this will not be efficient at all.

Then I figured I could get a larger more capable regulator (support 200,000BTU) and connect that to the manifold. That might work. However, then have concerns over how that gets distributed to the burners and if that's too much flow, etc.

So my current thought now is this. (Please refer to the attached image for more details)

Get an RV style hose that has the tool-less ACME connector on one end and a 1/4" male connector on the other end. Use this to connect the tank directly to the manifold (#1). There not be a regulator installed here. However, I have tested the manifold and it holds 14 PSI with no issues - so I think that'll be good. Next I can use adapters to convert the T-connectors from 1/2" down to 1/4" and attach 1/4" to Propane ACME adapters. That would allow me to then connect the original hoses (#2 and #3) from the Blichmann burners (using their regulators) directly to the manifold. This should regulate the pressures based on their regulators/specs.

In my mind, this makes sense. For the most part I would have 1/2" connections all the way up to the regulators (with the exception of a couple stepdowns for the 1/4" connectors. The hoses themselves are the standard 3/8" OD.

These might be dumb questions, but I'm new to the gas idea and BTU utilization, blah blah blah.

Thoughts?

pdxwarrior

Member

- Joined

- Feb 8, 2009

- Messages

- 6

- Reaction score

- 0

Didn't mean to post twice, browser was giving errors.

pdxwarrior

Member

- Joined

- Feb 8, 2009

- Messages

- 6

- Reaction score

- 0

I've been doing a little more reading. It looks like there are some pretty high pressures coming directly off of the propane tank itself. As such, I think I'll change up the idea a bit here.

Between tank and manifold - I'm going to see about getting a 200,000 BTU regulator with 1/4" or 1/2" connection and a Green Acme connector.

Coming off the burner connections - I will adapt from the 1/2" T-connector to a 1/4" connector and then back to an Acme adapter so I can tie in the original hoses/regulators that came with the burners.

My thinking is that the 200k BTU regulator will help manage the pressure inside the manifold itself and should be able to provide more than the burners will use. Then the original hoses/regulators will let me control the flame/gas better for each burner.

The only remaining question is, do I install a shutdown/ball valve at each burner connection so that I can shut off the gas when not using a particular burner...

Between tank and manifold - I'm going to see about getting a 200,000 BTU regulator with 1/4" or 1/2" connection and a Green Acme connector.

Coming off the burner connections - I will adapt from the 1/2" T-connector to a 1/4" connector and then back to an Acme adapter so I can tie in the original hoses/regulators that came with the burners.

My thinking is that the 200k BTU regulator will help manage the pressure inside the manifold itself and should be able to provide more than the burners will use. Then the original hoses/regulators will let me control the flame/gas better for each burner.

The only remaining question is, do I install a shutdown/ball valve at each burner connection so that I can shut off the gas when not using a particular burner...

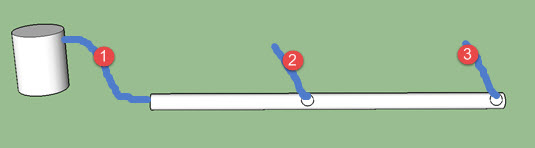

fwiw, I have a similar configuration, though both of my burners are Floor Burners. I used the supplied regulators as secondary regulators, and drive the manifold using a POL style high volume adjustable regulator at the cylinder, with a long hose to a conventional air pressure disconnect.

This shows the basic layout. I wouldn't recommend totally hard piping - it worked out for me but it was a challenge that two short flex couplings from the regulators to the burners would have much more easily solved.

Crappy picture but it shows the gas plumbing mounted on my rig...

Cheers!

This shows the basic layout. I wouldn't recommend totally hard piping - it worked out for me but it was a challenge that two short flex couplings from the regulators to the burners would have much more easily solved.

Crappy picture but it shows the gas plumbing mounted on my rig...

Cheers!

pdxwarrior

Member

- Joined

- Feb 8, 2009

- Messages

- 6

- Reaction score

- 0

Hey day_tripper - Thanks for the pictures, this was very helpful! I agree, trying to line up everything using solid tubing would add a whole other level of frustration! I referenced your stuff and talked with a local propane/bbq place. I modified what I had.. now I've got the regulator at the tank and then two needle valves coming off the main line (1/2" pipe) which then goes into flex hose to the burners. I'll get some more pictures together once I finish everything, but it's coming together nicely so far. (The plate chiller in the corner is just sitting there, I have since mounted it)

Similar threads

- Replies

- 0

- Views

- 659

- Replies

- 0

- Views

- 2K

- Replies

- 1

- Views

- 2K