mhermetz

Well-Known Member

Not sure why the photo didn't show.

I've been considering one of these and have read all reviews & threads I could find. I almost exclusively brew 5.5 gallon batches and want to make the move to electric. As expensive as it is, I think I'd bite if Blichmann offered a 240V, 10 gallon MT atop of a 15 gallon BK. Also, why wouldn't they make the auto sparge outlet tubing flow into a manifold of some kind that distributes the wort evenly over the entire grain bed like a fly sparge? Wouldn't that reduce the potential for channeling and the need to rake?

Off topic... the Unibrau (240V element) looks like an interesting setup...

https://brausupply.com/products/unibrau-all-in-one-electric-brew-system-v-3?variant=6116207165475

What watt density is that element? It looks kind of scorchy. Though that could be the low voltage one.

The Autosparge defeats channeling by pouring the wort back to the top of mash bed in a gentle swirling pool. It flows horizontally out of the hose, not straight down. For an all in one system, the BrewEasy is very efficient. The false bottom is the best in the industry.

Here's what you need:

Quick Release Therminator Chiller Bracket for Tower LTE

https://parts.blichmannengineering.com/product-p/aqr-chiller-bkt-lte.htm

Quick Release Bracket for mounting therminator chiller on the Tower of Power LTE.

You have to make certain that your stand has the two holes above the pump for the bracket. Before the quick release bracket, those holes didn't exist on older Lte stands.

I’m familiar with that bracket but I’m not excited about my Therminator being right above my chugger pump. It would seem that you have a high risk of dripping water into the pump as you’re connecting/disconnecting hoses.

Do you use that bracket?

There's three things that can be done to prevent dripping onto the pump:

1. Mount the therminator "upside" "down" so that the fittings are over the wet side of the pump.

2. Spin the pump around so that the head is under the fittings on the chiller

3. Change the process to where you connect the hoses to the chiller before placing it above the pump.

Bonus option: Create some sort of splash shield for the motor.

The RipTide doesnt have holes in motor so its not a concern to me. Just trying to help. Thanks for inviting me to play!

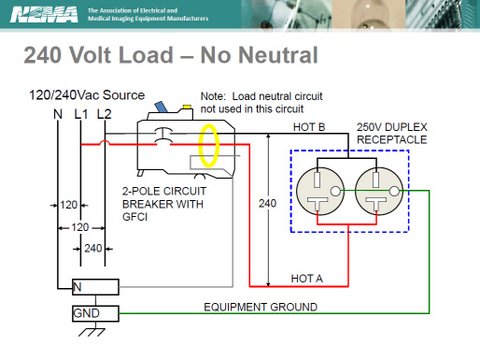

I wanted to ask if any Breweasy owners have encountered problems with regard to GFCI breakers tripping when connecting a Riptide pump via the Tower of Power LTE. I am able to heat up water in the brew kettle but as soon as I turn on the control module, with pump connected to the ToP, the breaker for the control panel trips. The strange thing is, the breaker trips even when the ToP is plugged in to another circuit, whereas everything is fine if the pump is plugged into an outlet directly. I thought perhaps it was user error, but Blichmann said they've heard of strange issues like mine but couldn't elaborate, so before I call the electrician I thought this was the best place to hear of strange issues....many thanks for any suggestions.

Edit: I should add that this is a 10 gallon, 240V version. I have a 30a breaker for the control panel/boil coil.

I did a 15G batch this weekend..33lbs grain..6oz of hops...22.5G of water total...i got 16G into fermenter..~72% Brewhouse eff.

For what it’s worth it took me several batches to get my volumes and efficiency dialed in. I dont know how long you’ve had the BE but it takes a few runs to start to dial it in. Hang in there...

I’ve been on the system for a few years...(this is year #4)

I started with 16 gallons of water, and ended up with about 8.5 of good wort...that’s under 60% efficiency. Now, I have my Brew Bucket filled with 6.5 gallons, and other carboy has about 2 galllons off usable wort + 2 gallons of hop trub.

I hit my OG, so I’m happy. But either I’m calculating efficiency wrong, or I have a poopy ton of loss.

Ive come close to 70% maybe once on a 12 gallon batch of 4% pale ale.

So folks out there are hitting 65-70% BH efficiency with a 10 gallon batch of 1.072 IPA with 14 oz of hops?