Brewed yesterday...still having efficiency issues. After reading this forum (several times), I think it has to do with the grain mill setting. To preface this, I have no control over the mill setting, it's done at the LHBS and they won't change it. They've offered to double-crush and add rice hulls, but most of you guys have said that it's a bad idea/would get a stuck mash, so I opted against that. I've attached 2 photos of what the grain looks like. Let me know if you think the grist isn't fine enough.

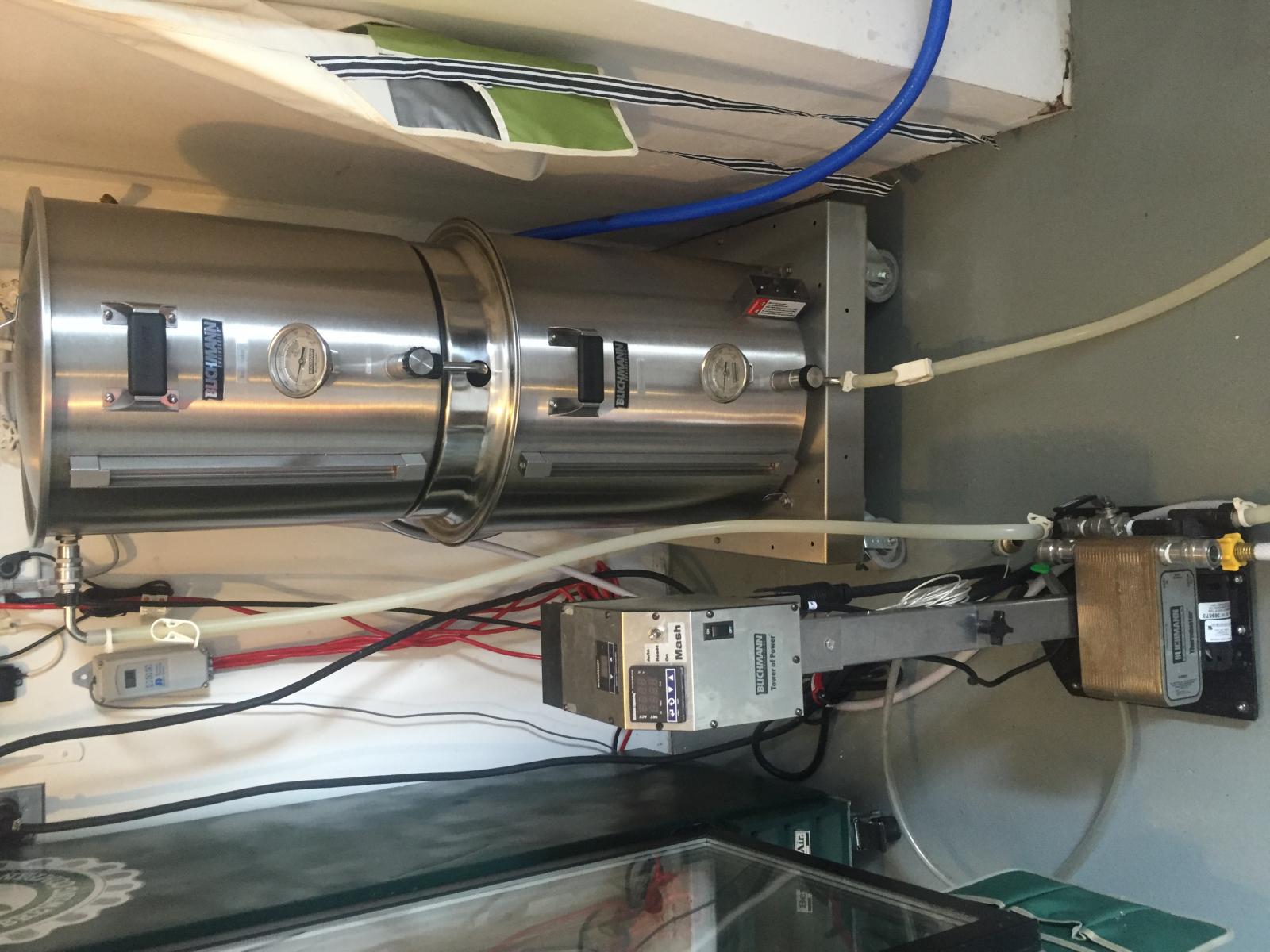

Also, when I brew 5 gallon batches, I'm having issues balancing my water between my 15 gallon MT and 20 gallon BK still. That issue being keeping my boil coil underwater so that it doesn't scorch. I've had portions of it out of the water a couple of times, scorching the coil (creating the smell of burnt toast) but never really affecting the beer's flavor. Has anybody ever had a beer ruined due to the coil scorching? Also, has anybody ever ruined a boil coil? When I go to clean it later, there is some black material on the coil, but it always comes off fairly easily.

Also, does anybody have an tips on using the Autosparge? It's always a balancing act that I have to constantly watch during the mash, altering the flow valve after the pump and the valve from the MT to BK. Once I get the balance, I don't have to worry about the boil surfacing. Any recommendations on using the Autosparge would be helpful! And SkullerKurt, I'm probably going to end up buying a RIMs rocket, probably the easiest way to fix this whole situation.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)