Surgeon and older kids.

Just an injection of dry wit.

Or is that a pun?

Just an injection of dry wit.

Or is that a pun?

I have to say, the XXL one would work perfect below my propane burner.Thanks for all the ideas! Apparently I'm a bit messier than most of you because I always spill something during the brewing or transfer or cleaning process. I've spill boiling wort, cleaning solution, hops/yeast that came out of the fermenter...lots of mishaps.

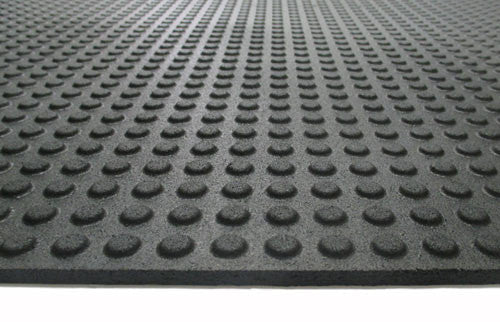

I'm not looking for a thousand dollar renovation to the floor but epoxy may be an option down the road. In the meantime, I'm thinking about going with something like this: Amazon.com

Maybe even something with sides on top of the placemat to catch a bit more spills from the Spike 20 gallon system.

https://www.amazon.com/gp/product/B0001N4700

What I'd really like is a large 6' x 6' rubber pad that's pitched towards the center with a lip around the edges. That way, any mess gets directed towards the center and I can sweep it up and/or drag the rubber mat outside when I need to hose it down.

How do people manage to turn brewing into an activity which creates as much stray moisture as a Super Soaker shootout? Do you epoxy coat your kitchen floors, as well? Brewing is a form of cooking and, in my experience at least, doesn’t have to be any messier than preparing dinner. Am I an outlier? In 10 years, and approximately 160 batches, I can’t recall having a spill which couldn’t be wiped up with an old towel.

This hobby is many things to many different people. If the important part of the hobby is “mimicking pro brewery stuff” then I suppose a floor drain is a necessity. If the hobby is about making good beer with a ghetto quality system, then it’s unlikely that cleaning up massive amounts of spillage is going to be a high priority. Different strokes, and all like that.If brewing is like cooking, it's like cooking in a large restaurant that makes house made soups every day. Once you add multiple vessels and a couple pumps, now you have plumbing that dumps liquids during disconnects. Yeast dumping and general cleaning of conicals can make a big mess too. The closer your process mimics pro brewery stuff, the more a floor drain is almost a necessity.

If I couldn't do epoxy, then I think I would go old school - VCT tiles and wax.

Why not use shag carpet? Soaks up spills and with patterns like this, you'll never notice any stains! Win, win.

View attachment 730101

You do need to rake it periodically to keep it looking nice though.

How do you deal with rain/snow schmutz on carpet tiles in the garage?

[...]Have a giant PVC mat on one side, which is where the car goes.[...]

How do you deal with rain/snow schmutz on carpet tiles in the garage?

Same here with no garage space. Time to haul it all away when she is at work.I would need a third - or even fourth garage bay to pull it off. We have so much crap in our two car garage that isn't "car" it's ridiculous

Cheers!

Good move going pro route, previous homeowner went diy in this house on 30 year old concrete. Don't think he adequately prepped before applying.I went the professional epoxy route- Works great, non slip and easy to clean up after brew day. My only regret was not having them do the coved epoxy base.View attachment 733459

Thanks for the info!! Im in the middle of remodeling the basement with a good sized brewing room in it and hopefully done soon? Already have done several batches and with the hose, tri clamp fittings etc, always a mess on the floor. 1 part epoxy for sure! No floor drain but am removing the concrete floor along the exterior wall and installing an infloor trench drain, 8' worth and running it into the drain tile so any mess easily squeegeed up. Walls done with 42" high metal roofing and water rock above. Should be able to spray water freely with out damage. Great info, thanks again!!I did epoxy flooring for a living for a while.

If you have bare concrete, 100% solids 2 part epoxy is impossible to beat. $150 USD or so per gallon, about 125 sqft per gallon. Anything cheaper and you should just use something else. Other epoxies may work, but are mich more finicky, some downright questionable.. Definitely don't use a 1 part, it's just paint at that point.

If you can't get it locally, you should again use something else. It's extremely dense. No chance shipping would make sense.

If I couldn't do epoxy, then I think I would go old school - VCT tiles and wax.

Idea behind epoxy or tiles for me is the same - I want to be able to squeegee it to clean up.

I would need a third - or even fourth garage bay to pull it off. We have so much crap in our two car garage that isn't "car" it's ridiculous

Cheers!