Turfgrass

Well-Known Member

I should clarify my question. Your water has low to moderate alkalinity, a reasonable level of Calcium and fairly high Sodium and Chloride (there must be a source of 'table salt' somewhere). Using distilled (why distilled; why not RO?) water for the mash means Calcium needs to be added. Your tap water will still need treating for the sparge, to prevent the pH from rising (astrigency) and throwing the boil pH out of whack. I helps to keep the pH on track throughout the entire brewing process if you use the same water throughout - in your case, you could use your tap water entirely, or blend 50/50 with RO/distilled. Acidify to a 5.4 pH and you'll be good for most beers! If you choose to split the water, I'd suggest going the other way - tap water for the mash (with salt additions) and distilled for the sparge.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

I figured it would be easier to build a water profile for the mash. Then add salts to the boil after sparging or direct to the HLT. The HLT holds 10gal so that the HERMS coil is completely submerged.

My town water is natural higher in Cl and Na. No table salts added on my end.

Good idea. I think cutting the tap water a bit will be helpful depending on the beer. I also want to do saison and milk stouts.Looking at your native water, you are not abnormally high in either Na or Cl. You are just at a spot where you don't want to add too much more Na to the mix. Using gypsum and Epsom salts, you can easily bring the Sulfate content up to a reasonable range. I would recommend shooting for around 15 ppm of Magnesium as a max and then bringing your Calcium up to above 50 ppm and less than 100 ppm. Neither of these will hurt you any.

I am not sure you need to add any DI water (which is close enough to distilled to use that in BS) but you can always add some to enable the addition of more Calcium and Sulfate to the mix. In this case, I would prep all your water together and add the DI water as part of that volume.

I would start on the Water profile tool to build your water using the materials you have available and then saving that combination of minerals and water supply as a Target Profile. You can then bring that profile into the recipe to match on the 'water' tab according to the actual water volume needed in the recipe. This way if everything works out, you will not need to keep rebuilding your water profile every time you go to brew a new recipe.

I’ll mess around the water calculator tonight, but last time I thought I couldn’t hit my target Cl and S targets and the reason for blended waters.I wasn't suggesting that you added table salt, I was saying it must get into your town water supply in some way (hence the Na and Cl).

If I had your water (assuming it tastes good and you can easily remove chlorine), I wouldn't bother with RO/DI. I would use tap water for the whole brewing process. Acidify the mash and sparge as needed.

The problem in my mind seems to be treating water in two different vessels, MT and HLT. I could treat ten gallons in the HLT and then transfer to the MT, but I will still have to top off the HLT again to cover the HERMS coil. There must be an easier way to go about this, otherwise I’d have to use a different program, such as, BF and calculate different water quantities.

Need 10 gallons in HLT at all time. Then add about 4 gallons to MT and sparge with about 3.5.

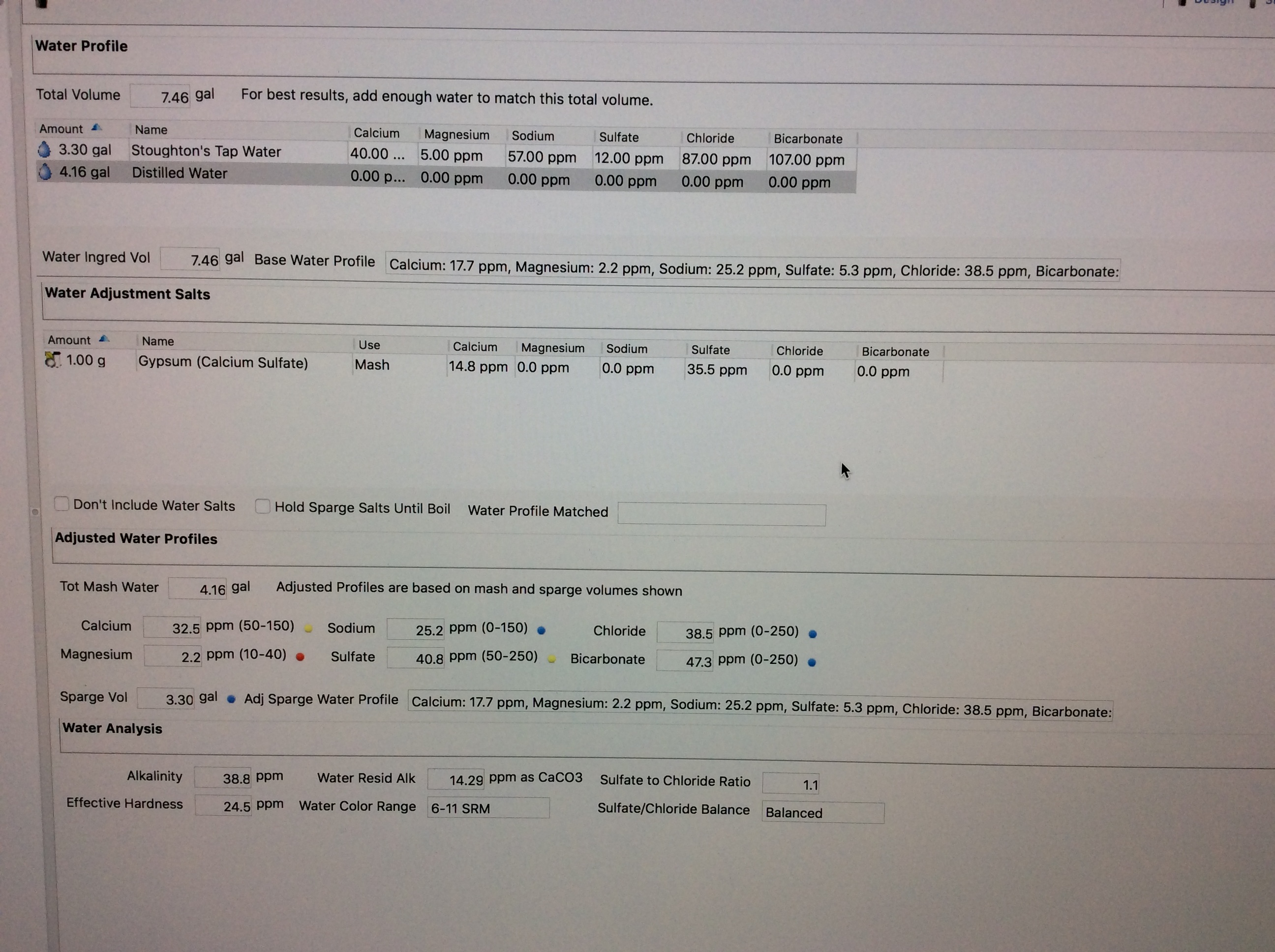

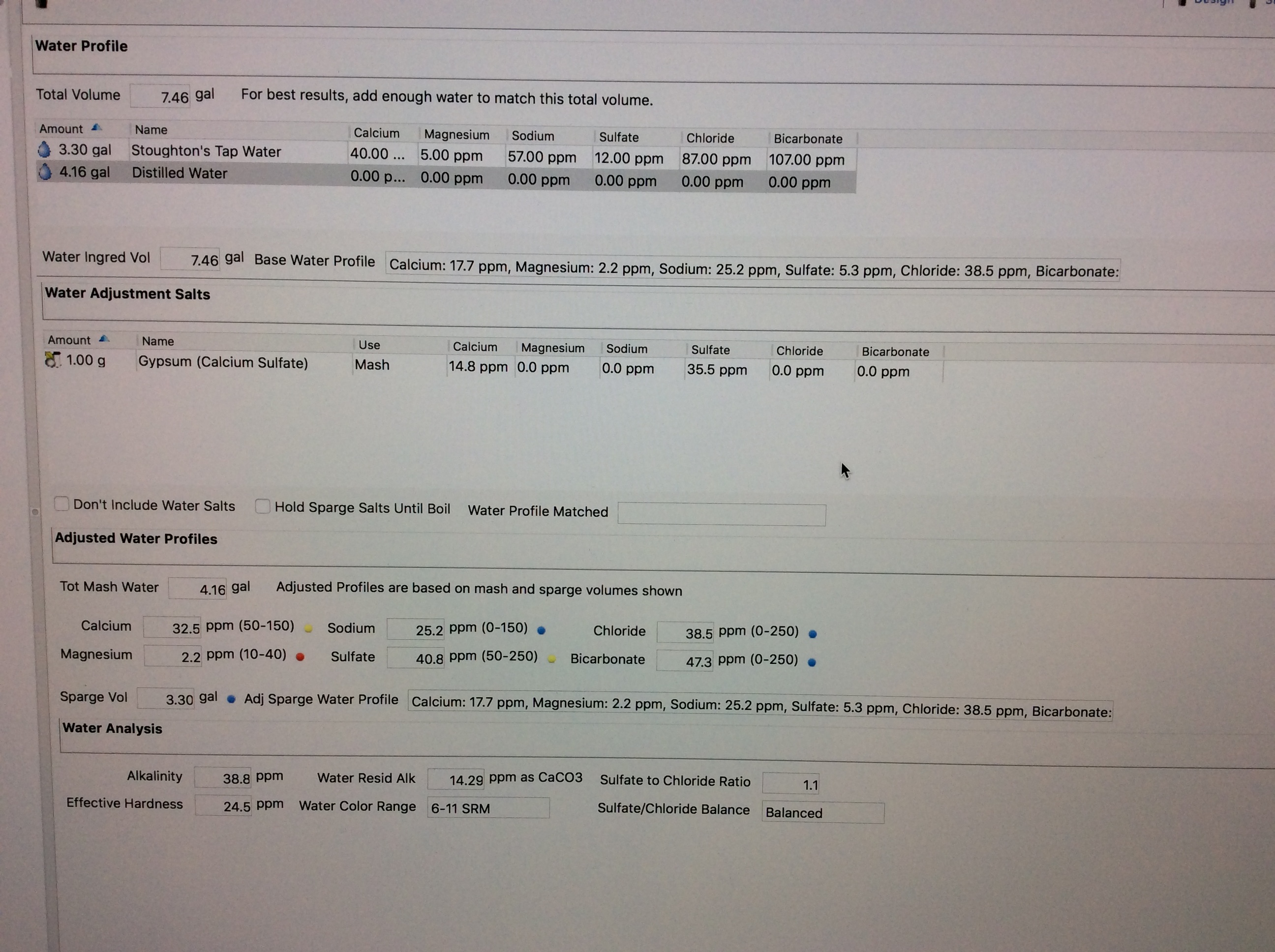

View attachment 608530 I’m trying to figure out the salt additions for two water chemistry’s with BS3 and my HERMS. The desicion has been to use distilled water for the mash and tap water for the sparge. The HLT tank will hold 10 gallons of modified water for sparge and cleanup. How do I keep the two water additions separate from a single calculation? I want to make sure my mash and sparge water are correct when it become brew time. Any suggestions would help.

Hi and thanks. I’d like to just use the town tap water, but where it is high in a couple values it makes certain elements higher than I would like. At least when it comes to experimenting.If you are only going to treat your tap water, and the tap water will be going into the mash tun, set all of your water in the calculation to be "Stoughton's tap water". Then it will tell you what minerals you need to add to hit your target profile in your mash based on your tap water.

If you plan on using distilled in the HLT with no mineral additions, you won't need to put that into the calculation.

If you want to know what your actual water profile is once you mix your MLT water with your sparge water, you can use the water tool in beersmith. Go to tools and "water profile tool". This tool allows your to dilute a water profile with another water source. This tool will also allow you to adjust your mineral additions in your MLT to hit your target profile once it is diluted with your sparge water.

I usually just use the same water in both the HLT and MLT, as it makes things a lot simpler.

Hi and thanks. I’d like to just use the town tap water, but where it is high in a couple values it makes certain elements higher than I would like. At least when it comes to experimenting.

I messed around with the BF program last night and it seemed a bit easier, however, I would be adding the sparge salts to the boil kettle after sparging. I could have calculated for the entire HLT volume of ten gallons, but didn’t want to waste phosphoric acid.

I’ll double check the water tool profile on BS3.