I suppose it wouldn't be extremely hard to unplug the BCS and plug PIDs in, if need be (I understand there would be more wiring and what not, but if you are using your BCS as just a replacement for PIDs this shouldn't be too hard).

You'd have to add or completely redo your cabinet/enclosure as you'd need 1/16 DIN sized cutouts to add the PIDs. That to me is basically starting over as you're redoing a cabinet/enclosure (the bulk of the work).

For the internet control, the reason I want internet control is I can have my GF (who goes home for lunch during the week) fill up my HLT and I can fire it up right as I leave work and by the time I commute home, I can be ready for mashing. This way I can start earlier and finish earlier during the work week.

That's a good example of how it's useful. Thanks!

That said, maybe it's just me, but I feel that powerful/dangerous systems like a 30+ amp brewing setup should not be controlled remotely either. The operator should be on location (or at least in the house). It scares me to think that something this powerful is purposely built for remote control.

Not saying PIDs are limited but if I can do everything all in one box, why wouldn't I want to?

Easy: For safety reasons. Having a centralized system on all the time that controls wort creation (the brew house), the fermentation chamber, and kegerator seems dangerous. I made a conscious decision to separate them completely, just in case.

What if you're sitting at work (or even just another room in the house) and decide you want to raise the fermentation temp slightly ... and doing so you mistakely click somewhere on a screen by accident (not even realizing it) and turn on one of the kettle elements? Or have the control through your iPad or something and it falls off the couch and brushes against the screen?

And what if something actually failed? An SSR died closed for example. Again one of the heating elements could all of a sudden fire up in an empty kettle in the middle of the night, or when someone's gone all day to work. If fermentation or kegerator control fails, the worst thing that can happen is loss of temperature control. If the brewing control fails when you're not around, you could burn the house down.

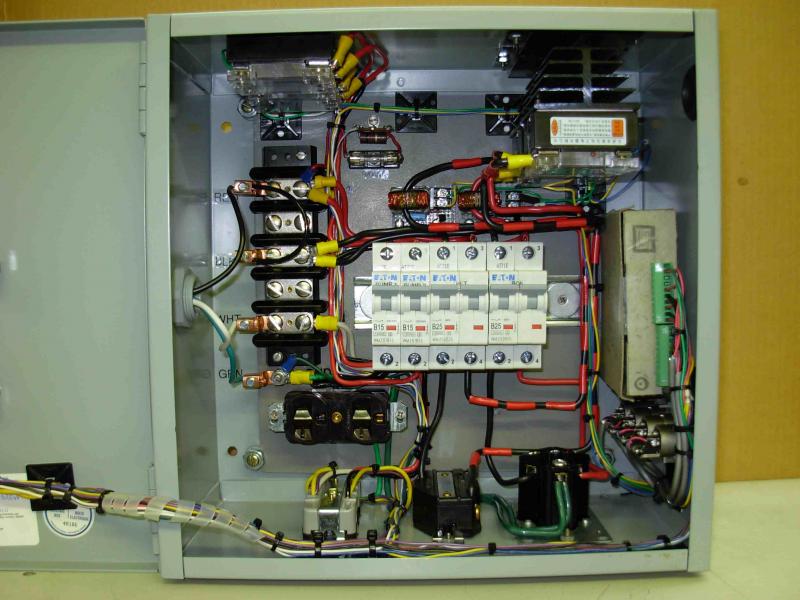

I don't unplug my control panel at the end of the brew day but I do turn it off so that this cannot possibly happen (in addition to safety interlocks). I have to physically be there to turn it on, and I physically turn it off when done. I designed it like this on purpose. It can only be controlled on location. If you have one computer system (the BCS) controlling multiple systems the problem is compounded since you need to leave it on all the time since you're probably fermenting 50% of the time and the kegerator is controlled 100% of the time so you can't turn off the system. That's just inherently dangeous.

You can't just put extra interlock switches in to make sure that dagerous things like pumps and elements won't turn on when you don't mean to because again you're assuming that the operator will remember to use them. Things built for safety can't only be safe if people only remember to use them. It has to be forced upon them. Think about the heavy equipment operator that has to press two buttons at the same time using both hands because the buttons are far enough apart. That's a good example of proper safety design as it ensures they and their hands are outside the machine before it does its job. (Until they duct tape one of the buttons down of course

but a well designed system won't allow that because it'll expect open/close action on the switches for every machine cycle).

Kal

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)