TheMagicHatter

Well-Known Member

Hey gang. I'm finally going to be brewing my first all grain batch tomorrow. It's a pale ale recipe that has turned out incredibly well in my extract batches.

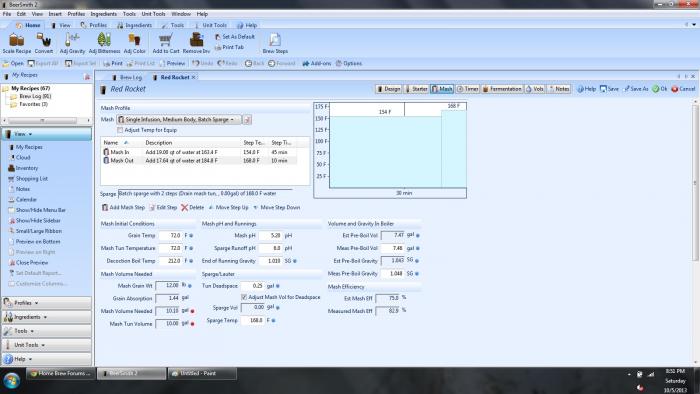

I've been playing around in Beersmith trying to understand my batch sparge volumes and can't seem to understand what it's telling me. I've searched the forums and others have had the same issue, but I still can't wrap my head around this.

My grain bill is 10.75lbs which will end up being about 13.44 qts/3.36gal of water for the strike water. So far so good, I think. Now I'll heat that water to around 168 degrees, dump it into my 10 gallon cooler and stir in the grains and allow it to sit for 60 mintues, correct?

Beersmith then tells me I need to batch sparge with 3 steps(posted below). Why 3 steps? Why can't I pour the entire volume of .19gal, 2.26gal and 2.26gal in at all one time, drain, then boil?

I'm trying to end up with around 5 gallons post boil.

------------------------------------

Type: All Grain Date: 1/6/2013

Batch Size (fermenter): 5.00 gal Brewer:

Boil Size: 6.52 gal Asst Brewer:

Boil Time: 60 min Equipment: Pot and Cooler ( 5 Gal/19 L) - All Grain

End of Boil Volume 5.98 gal Brewhouse Efficiency: 72.00 %

Final Bottling Volume: 4.60 gal Est Mash Efficiency 82.8 %

Fermentation: Ale, Two Stage Taste Rating(out of 50): 30.0

Taste Notes:

Ingredients

Ingredients

Amt Name Type # %/IBU

9 lbs Pale Malt (2 Row) US (2.0 SRM) Grain 1 83.7 %

1 lbs Caramel/Crystal Malt - 40L (40.0 SRM) Grain 2 9.3 %

12.0 oz Cara-Pils/Dextrine (2.0 SRM) Grain 3 7.0 %

1.00 oz Magnum [13.70 %] - Boil 60.0 min Hop 4 45.5 IBUs

0.50 oz Cascade [7.30 %] - Boil 15.0 min Hop 5 6.0 IBUs

0.50 oz Cascade [7.30 %] - Boil 5.0 min Hop 6 2.4 IBUs

1.0 pkg American Ale (Wyeast Labs #1056) [124.21 ml] Yeast 7 -

1.00 oz Cascade [5.50 %] - Dry Hop 21.0 Days Hop 8 0.0 IBUs

Beer Profile

Est Original Gravity: 1.056 SG Measured Original Gravity: 1.046 SG

Est Final Gravity: 1.015 SG Measured Final Gravity: 1.010 SG

Estimated Alcohol by Vol: 5.3 % Actual Alcohol by Vol: 4.7 %

Bitterness: 54.0 IBUs Calories: 151.6 kcal/12oz

Est Color: 7.4 SRM

Mash Profile

Mash Name: Single Infusion, Full Body, Batch Sparge Total Grain Weight: 10 lbs 12.0 oz

Sparge Water: 4.70 gal Grain Temperature: 72.0 F

Sparge Temperature: 168.0 F Tun Temperature: 72.0 F

Adjust Temp for Equipment: FALSE Mash PH: 5.20

Mash Steps

Name Description Step Temperature Step Time

Mash In Add 13.44 qt of water at 168.2 F 156.0 F 45 min

Sparge Step: Batch sparge with 3 steps (0.19gal, 2.26gal, 2.26gal) of 168.0 F water

Mash Notes: Simple single infusion mash for use with most modern well modified grains (about 95% of the time).

I've been playing around in Beersmith trying to understand my batch sparge volumes and can't seem to understand what it's telling me. I've searched the forums and others have had the same issue, but I still can't wrap my head around this.

My grain bill is 10.75lbs which will end up being about 13.44 qts/3.36gal of water for the strike water. So far so good, I think. Now I'll heat that water to around 168 degrees, dump it into my 10 gallon cooler and stir in the grains and allow it to sit for 60 mintues, correct?

Beersmith then tells me I need to batch sparge with 3 steps(posted below). Why 3 steps? Why can't I pour the entire volume of .19gal, 2.26gal and 2.26gal in at all one time, drain, then boil?

I'm trying to end up with around 5 gallons post boil.

------------------------------------

Type: All Grain Date: 1/6/2013

Batch Size (fermenter): 5.00 gal Brewer:

Boil Size: 6.52 gal Asst Brewer:

Boil Time: 60 min Equipment: Pot and Cooler ( 5 Gal/19 L) - All Grain

End of Boil Volume 5.98 gal Brewhouse Efficiency: 72.00 %

Final Bottling Volume: 4.60 gal Est Mash Efficiency 82.8 %

Fermentation: Ale, Two Stage Taste Rating(out of 50): 30.0

Taste Notes:

Ingredients

Ingredients

Amt Name Type # %/IBU

9 lbs Pale Malt (2 Row) US (2.0 SRM) Grain 1 83.7 %

1 lbs Caramel/Crystal Malt - 40L (40.0 SRM) Grain 2 9.3 %

12.0 oz Cara-Pils/Dextrine (2.0 SRM) Grain 3 7.0 %

1.00 oz Magnum [13.70 %] - Boil 60.0 min Hop 4 45.5 IBUs

0.50 oz Cascade [7.30 %] - Boil 15.0 min Hop 5 6.0 IBUs

0.50 oz Cascade [7.30 %] - Boil 5.0 min Hop 6 2.4 IBUs

1.0 pkg American Ale (Wyeast Labs #1056) [124.21 ml] Yeast 7 -

1.00 oz Cascade [5.50 %] - Dry Hop 21.0 Days Hop 8 0.0 IBUs

Beer Profile

Est Original Gravity: 1.056 SG Measured Original Gravity: 1.046 SG

Est Final Gravity: 1.015 SG Measured Final Gravity: 1.010 SG

Estimated Alcohol by Vol: 5.3 % Actual Alcohol by Vol: 4.7 %

Bitterness: 54.0 IBUs Calories: 151.6 kcal/12oz

Est Color: 7.4 SRM

Mash Profile

Mash Name: Single Infusion, Full Body, Batch Sparge Total Grain Weight: 10 lbs 12.0 oz

Sparge Water: 4.70 gal Grain Temperature: 72.0 F

Sparge Temperature: 168.0 F Tun Temperature: 72.0 F

Adjust Temp for Equipment: FALSE Mash PH: 5.20

Mash Steps

Name Description Step Temperature Step Time

Mash In Add 13.44 qt of water at 168.2 F 156.0 F 45 min

Sparge Step: Batch sparge with 3 steps (0.19gal, 2.26gal, 2.26gal) of 168.0 F water

Mash Notes: Simple single infusion mash for use with most modern well modified grains (about 95% of the time).

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

I knew Beersmith was a powerful little program, but had no idea I could do something like this. The recipe is starting to look a bit better and easier to understand, then again, I'm likely over thinking the whole process as it is!

I knew Beersmith was a powerful little program, but had no idea I could do something like this. The recipe is starting to look a bit better and easier to understand, then again, I'm likely over thinking the whole process as it is!