olse0230

Member

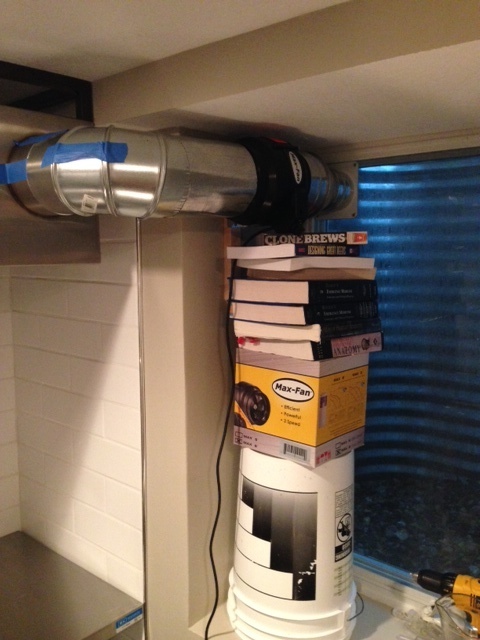

I finally made the leap to an indoor E-HERMS brewery in my basement after years of brewing in my garage, hauling supplies from the basement upstairs for every brew day, transfer and kegging. Minnesota winters are not conducive for fun brew sessions, even in a garage. We had an unused basement bedroom that I got the green light from my wife to turn into a brewery. Having learned so much from other basement brewery threads, I'm starting my own thread to hopefully some others who are aspiring to build a brewery in their basement. It's so far been 4 months, countless trips to Home Depot, Menards and the Tile Shop, lots of YouTube videos, and one good hand laceration and I'm almost done.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)