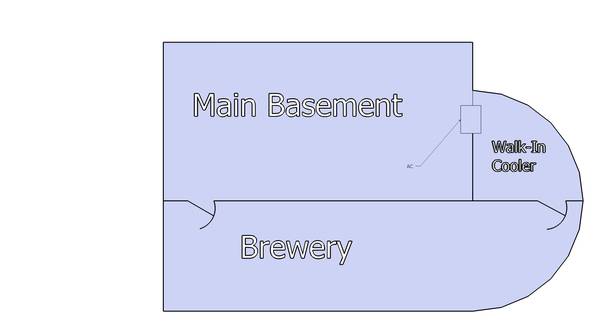

With all that space downstairs, a walk-in is very doable so I did. The space is curved so I walled off a quarter circle. The resulting space is about 43 square feet, if I remember my trig. right. My builder has some extra time on his hands (what a surprise) so he gave me a good deal on a quick-and-dirty build. (He is a very nice guy but he thinks all these DIY custom things I'm doing are a bit nuts).

Here is the before shot:

Here are the after shots:

I made all the walls R30 sheathed with "Green Board" and a vapor barrier on the outer layer. The pre-existing wall shared with basement was already insulated to R12 so I added foam board there. I will put more foam board on the steel/foam core exterior-grade door. The floor is still concrete until I figure out a better idea.

As you can see from the plan the A/C unit vents to the main basement. I am below grade so venting outside would be pain. I figure in the winter I'll get back some heat for the house but the basement is big enough that there isn't a huge heat contribution.

There is a problem though. I have to keep some part of the AC hot side protruding out the back to prevent overheating...

but the block wall is 8 inches thick and the there are mucho mas inches of insulation on the cooler side so the AC is deeply recessed.

Now I plan to hack the thermostat of this LG 12k btu unit from Costco but I already have an issue. Ambient temps in the main basement are about 72 deg. Ground temps below grade are about 65 deg. The AC should at least be able to get the room down to the lowest temp on the stock thermostat, 60 degrees, but 65 is the best I can do. The unit cycles on for literally one minute then is off for a few. I suspect the cavity gets much colder than the room (or the a/c is defective). I detached the frost sensor from the radiator fins, stuck it in a foam peanut as a buffer, and placed it outside the cavity but this changed absolutely nothing! I also considered a fan blowing INTO the cavity to mix the air better.

Is the thermostat sensor somewhere else? Can I make it remote? I'd like to understand this issue before customizing things. Thanks.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)