artbrau

Well-Known Member

THE SPACE.

When we built our house I had the contractor fully excavate the area under the porch to make an brewing room off the basement. Now, a year later, I'm finally getting around to setting the thing up.

The ceiling is insulated and cement block separates it from the rest of the basement so it stays reasonably cool in the summer. I put in the kitchen cabinets from a house I tore down. The space is big, about 12x30, and wraps around the corner of the house. I would like to put a walk-in cooler at that end some day. There french drains, floor drains, gas, water and an old dishwasher (no, not me).

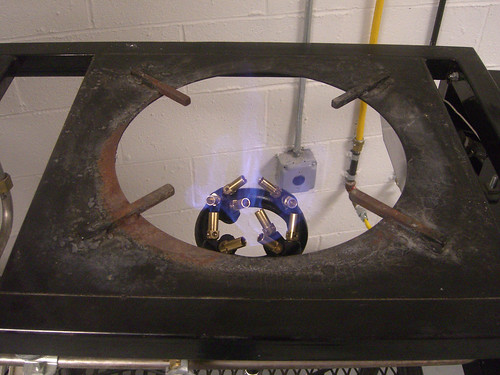

In the next few posts in this thread I'll document some of the more interesting bits: The brewing stand mods, the ventilation system and water treatment.

When we built our house I had the contractor fully excavate the area under the porch to make an brewing room off the basement. Now, a year later, I'm finally getting around to setting the thing up.

The ceiling is insulated and cement block separates it from the rest of the basement so it stays reasonably cool in the summer. I put in the kitchen cabinets from a house I tore down. The space is big, about 12x30, and wraps around the corner of the house. I would like to put a walk-in cooler at that end some day. There french drains, floor drains, gas, water and an old dishwasher (no, not me).

In the next few posts in this thread I'll document some of the more interesting bits: The brewing stand mods, the ventilation system and water treatment.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

BTW, I am desperately jealous of your brewing space. Mine is outside, in the heat or cold and I don't have much choice but to store my gear in the garage, 15 feet from the cat litter...

BTW, I am desperately jealous of your brewing space. Mine is outside, in the heat or cold and I don't have much choice but to store my gear in the garage, 15 feet from the cat litter...