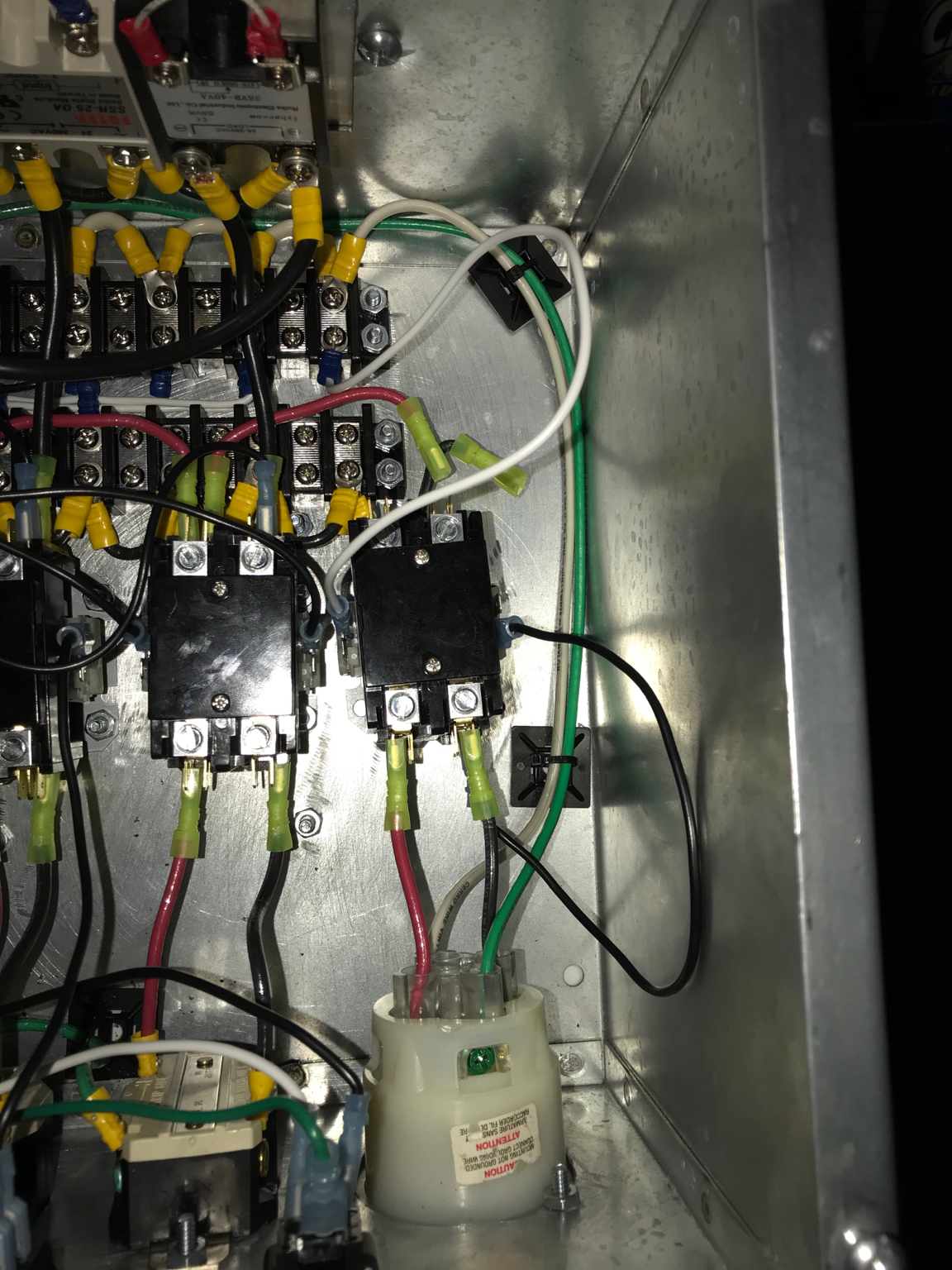

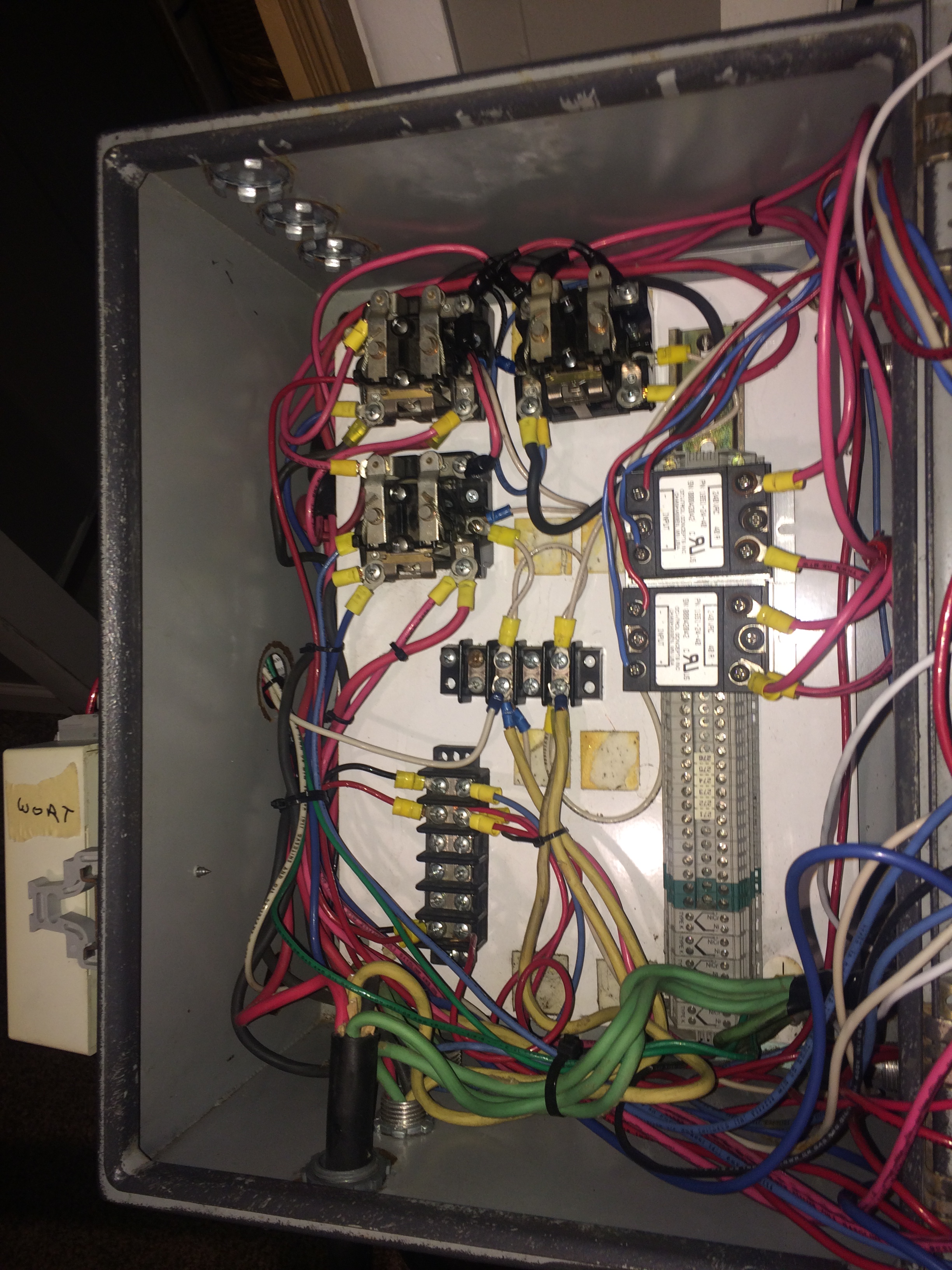

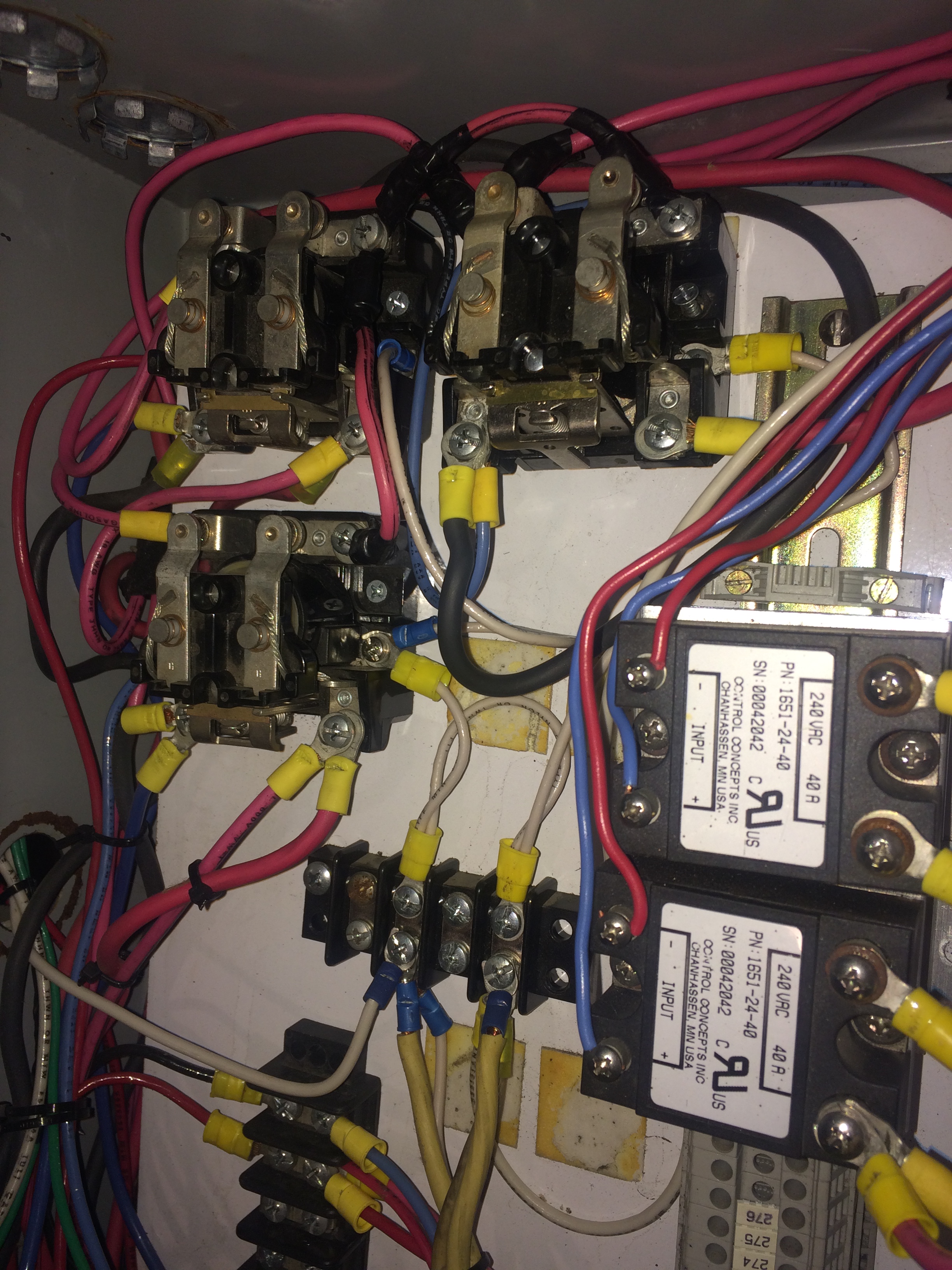

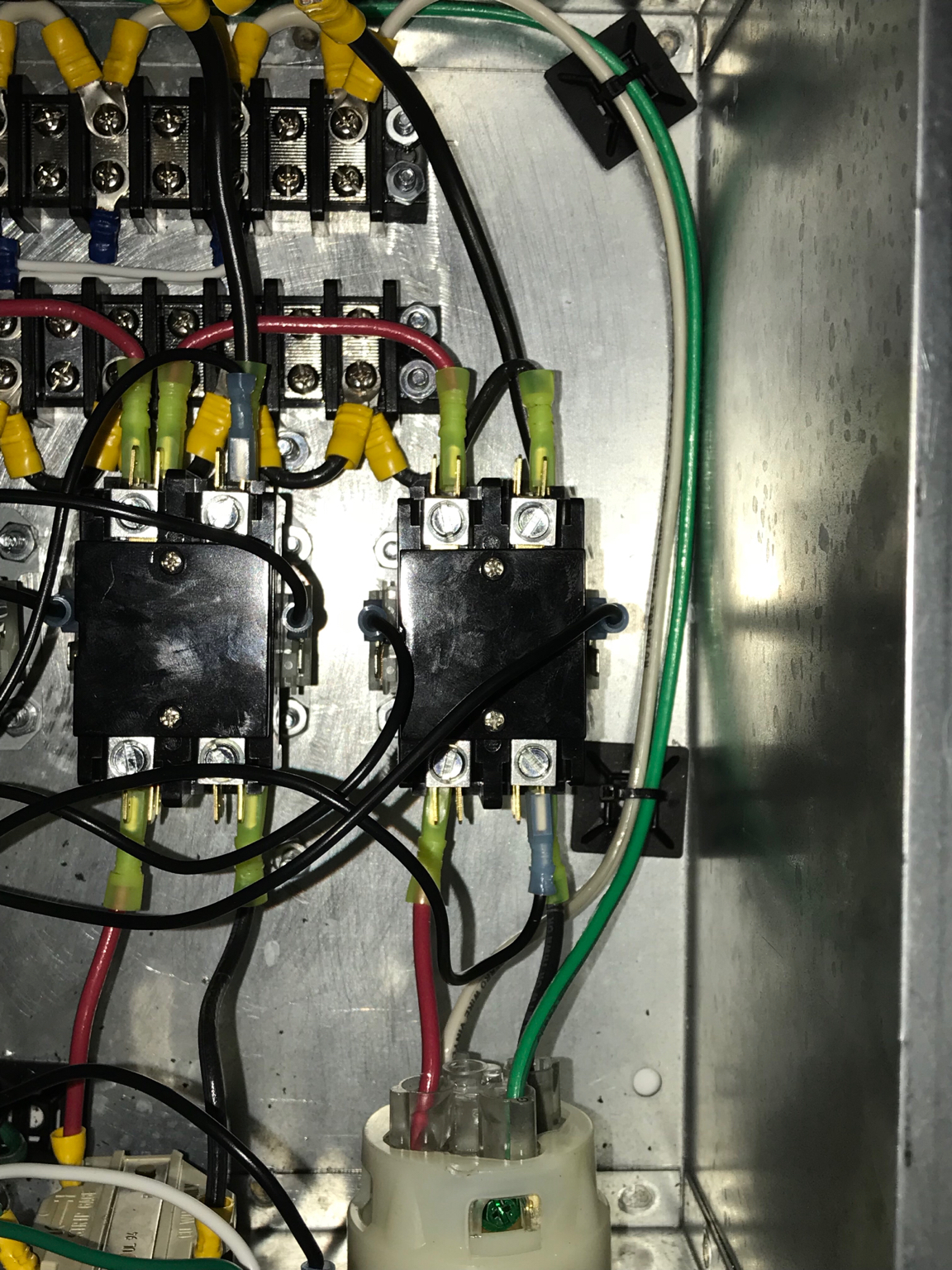

I’m finally in the testing phase of my Brew Panel I wired up—

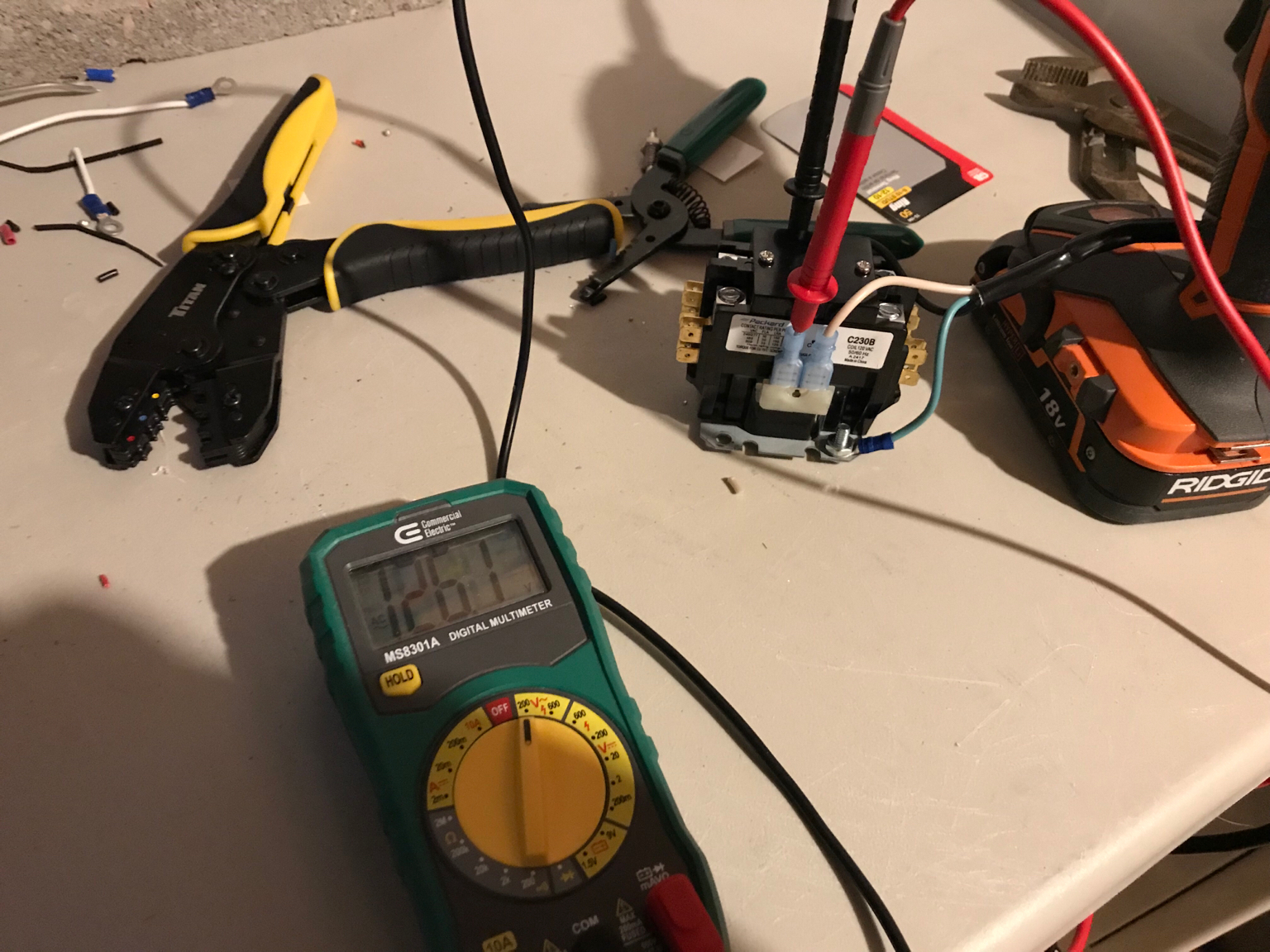

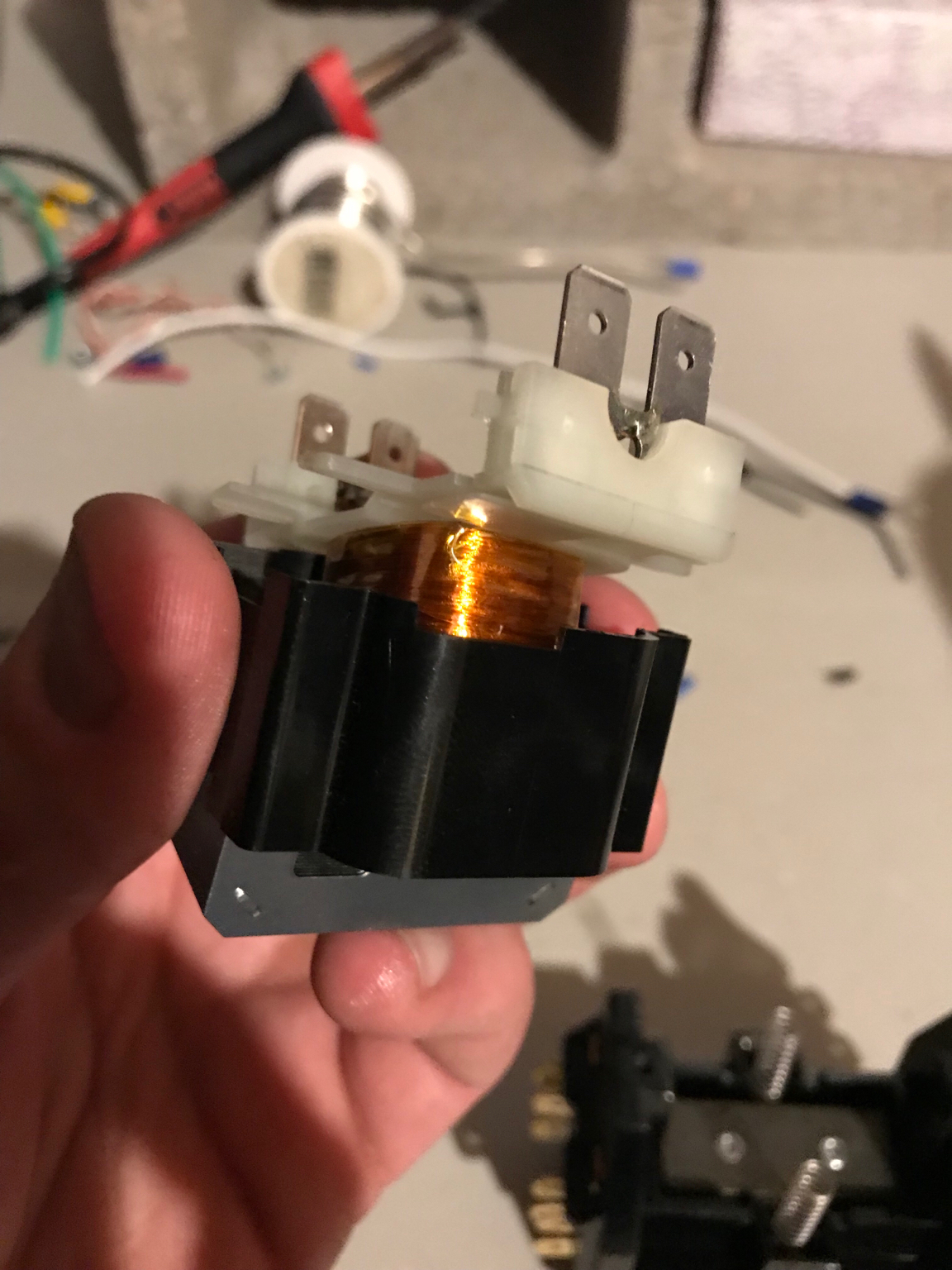

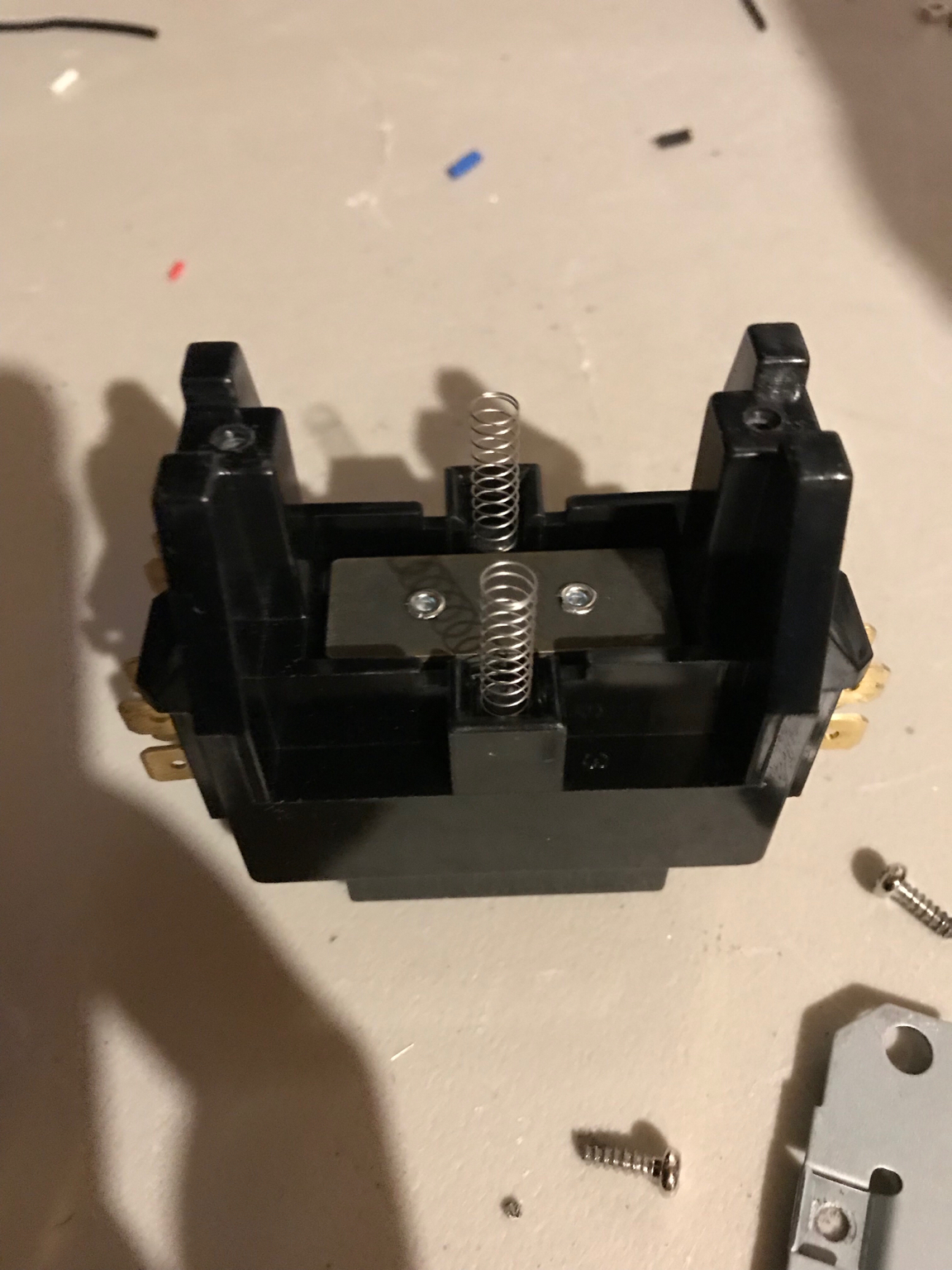

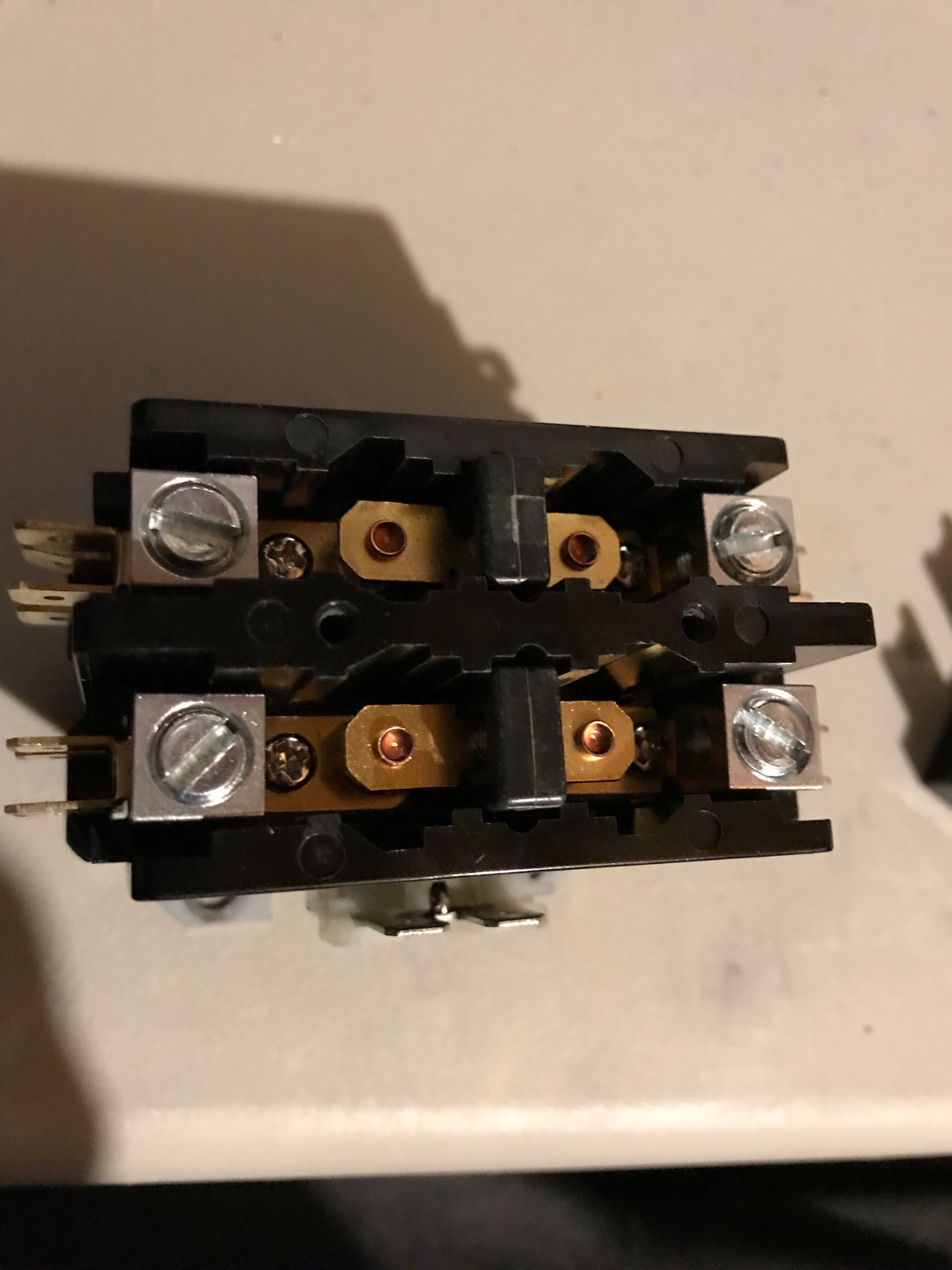

When I turn the system on, the power indicator wired on the other side of the contactor coil lights up. The 240v legs on the other side of the contractor are carrying no current though (checked w/ a volt meter).

Is there something I’m missing or do I have a dud?

When I turn the system on, the power indicator wired on the other side of the contactor coil lights up. The 240v legs on the other side of the contractor are carrying no current though (checked w/ a volt meter).

Is there something I’m missing or do I have a dud?

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)