One more thing. These valves have the highest flow rating because the cv plate in them is almost nonexistent. You could buy one with a lower CV rating and just pull the disk out. Probably will save u a fee $$.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

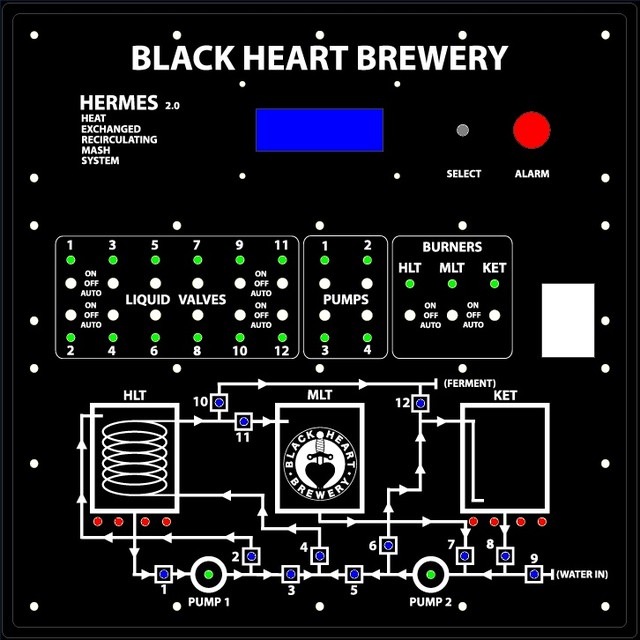

Automated HERMS system

- Thread starter blackheart

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

dentid4h3d

New Member

Curtis from midwestBAS.com here, and I just wanted to say, on behalf of all of us, thank you! We had no idea you could use these guys in a "Lazy Automated Brew System". Should you ever need more, or if anyone should come to us from this forum, give me a call directly, I'd be happy to try to come up with a "Beer Brewers" coupon or something.

866/313.2207 -- Just ask for Curtis or Dave and mention homebrewtalk.com

866/313.2207 -- Just ask for Curtis or Dave and mention homebrewtalk.com

Im sure being a vendor sponsor on here would help!

blackheart

Well-Known Member

Thanks guys, I gave curtis a call and I think we will be able to find the valve/actuators we need. Really cool company as they sell to end users like us, not just people with corp accounts. Also, I hear the owner is a home brewer himself.

BrewBeemer

Well-Known Member

Discount, Discount, Discount, maybe he can become a vendor on HBT we can help with his valve sales?

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$159.50 ($26.58 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

blackheart

Well-Known Member

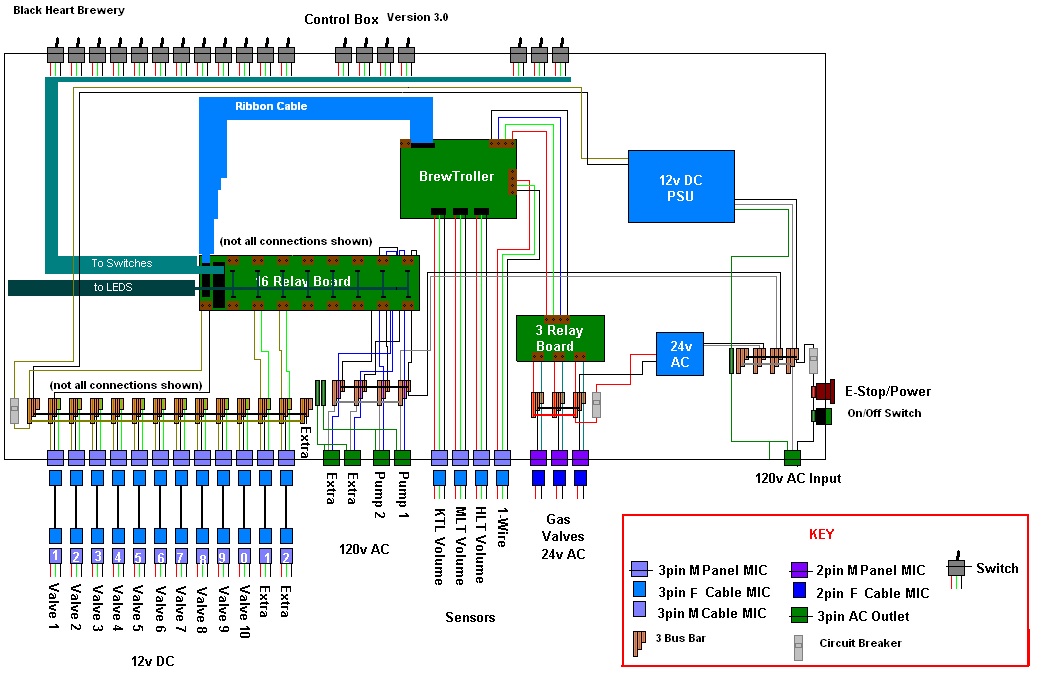

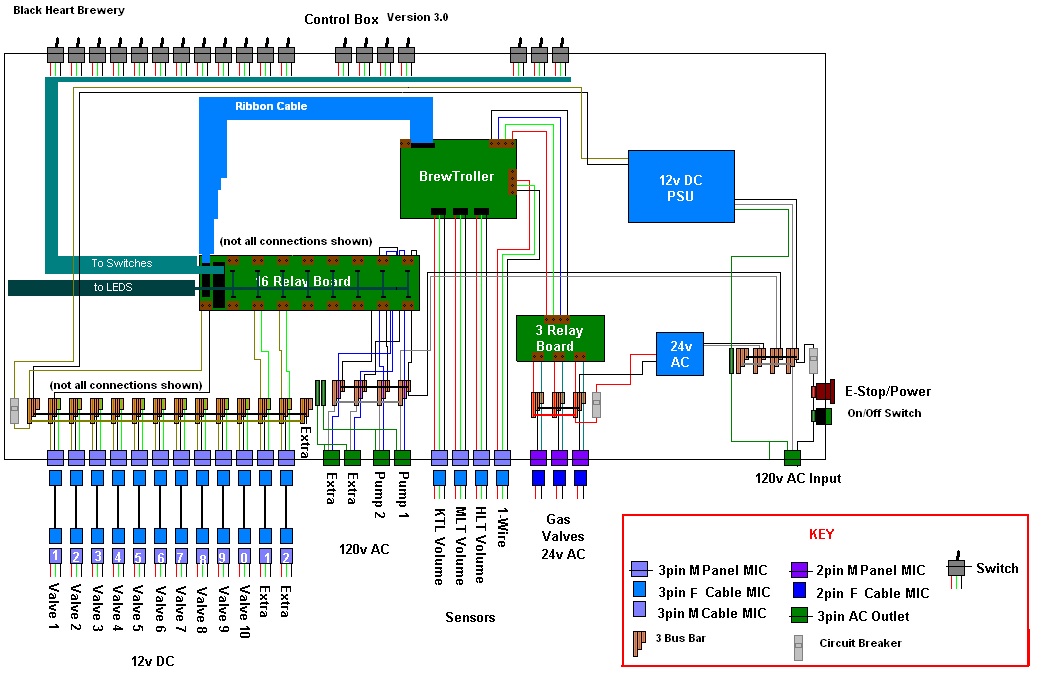

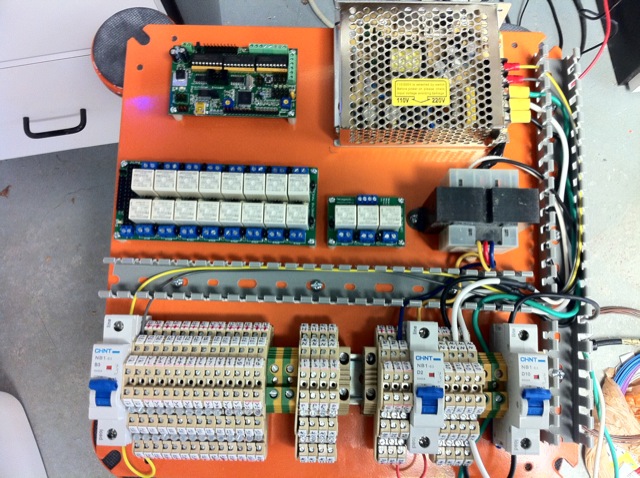

Working on revamping the entire electrical in a real enclosure with fuses/breakers and nice automation type parts etc. as well as BrewTroller automation.

Here are the power requirements for all of the pieces so I can figure out circuit breakers to use etc.

Power Requirements

24V Transformer [10A @ 120v MAX draw]

PSU 12v [3A @ 120v]

12x valves 12v @ 80MA = [960MA @ 12v]

3x Gas Valves 24vac @ 0.5A = [1.5A @ 24v]

4x Pumps 1.4A @ 120v [5.6A @ 120v]

Brew Troller 12v @ [1A @ 12v]

Relays 30ma @ 12v x 19 = [570MA @ 12v]

Total AC Available ?? (must check switch box)

Total AC Drawn 5.6A + 3A + 2A = 10.3A MAX

Total DC Available 3A

Total DC Drawn 2.53A (max)

Total 24v AC Available 10A

Total 24v AC Drawn 1.5A (max)

So it looks like about ~10A max draw with everything on... I assume I use a 10-12A breaker on the AC lines? This is assuming all parts are on and at full draw etc....

Also, should I add breakers to the 12v and the 24v lines to protect the PSU and transformer individually? Should I be fusing each device (pumps etc) individually?

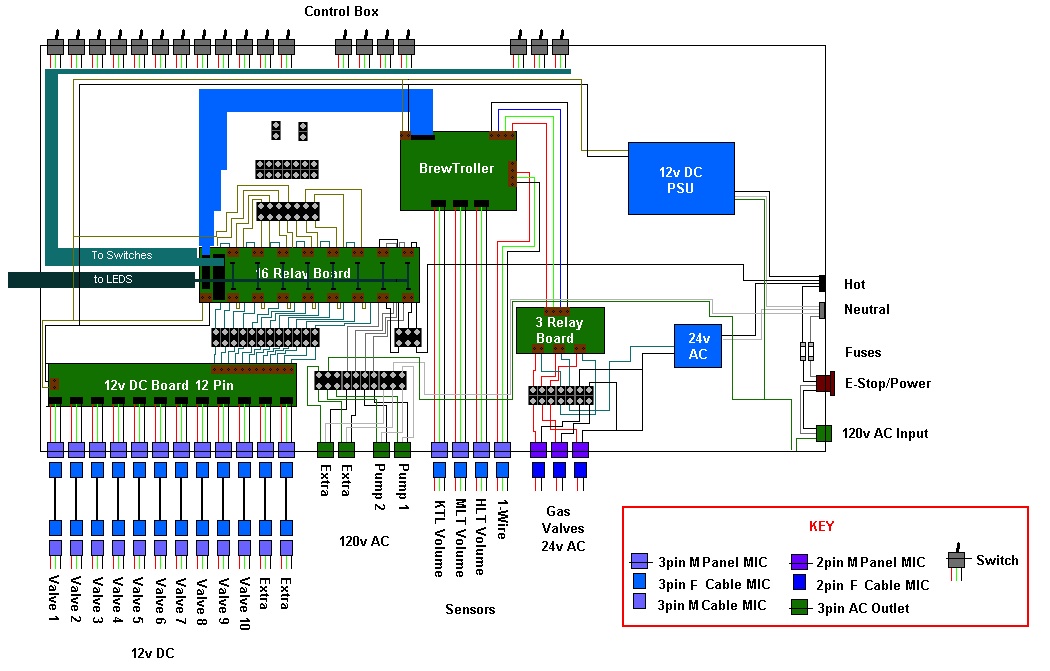

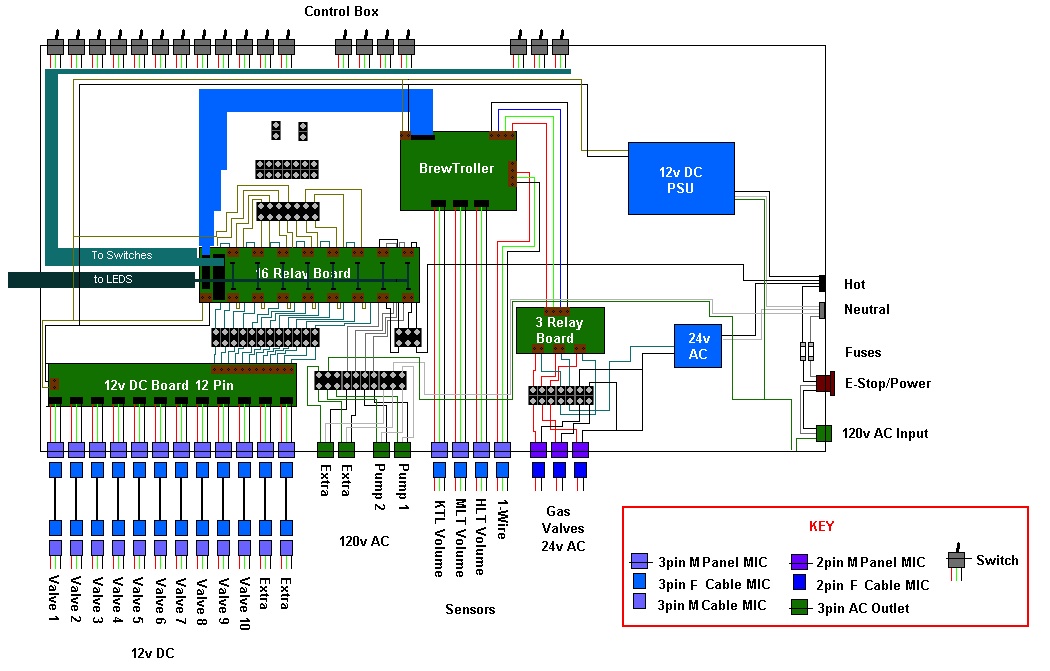

Here is a rough draft of the wiring diagram for the electronics.

Trying to spec everything out down the the last wire gauge/color and connector type so we can order everything then just sit down and wire it all up. Also contemplating a custom built box thats pre painted and punched with all of these holes.

Most likely will have to order everything before we decide on a final layout and can roughly lay things out on cardboard. Also, this box will be mounted on most likely a swinging arm on the right side of the brewing system enabling better control and wire management etc. Some pictures of that will be coming soon.

We already ordered 70 MIC connectors for most of the IO of various types. Next order is for the Brew Troller boards etc and the valves, about $700 worth of parts. Hoping to get a jump on this while we have some time off over the holidays.

Right now we could really use help in selecting circuit breakers, E-stop button, 20x switches, and general automation parts like DIN rails, distribution blocks etc.

Here are the power requirements for all of the pieces so I can figure out circuit breakers to use etc.

Power Requirements

24V Transformer [10A @ 120v MAX draw]

PSU 12v [3A @ 120v]

12x valves 12v @ 80MA = [960MA @ 12v]

3x Gas Valves 24vac @ 0.5A = [1.5A @ 24v]

4x Pumps 1.4A @ 120v [5.6A @ 120v]

Brew Troller 12v @ [1A @ 12v]

Relays 30ma @ 12v x 19 = [570MA @ 12v]

Total AC Available ?? (must check switch box)

Total AC Drawn 5.6A + 3A + 2A = 10.3A MAX

Total DC Available 3A

Total DC Drawn 2.53A (max)

Total 24v AC Available 10A

Total 24v AC Drawn 1.5A (max)

So it looks like about ~10A max draw with everything on... I assume I use a 10-12A breaker on the AC lines? This is assuming all parts are on and at full draw etc....

Also, should I add breakers to the 12v and the 24v lines to protect the PSU and transformer individually? Should I be fusing each device (pumps etc) individually?

Here is a rough draft of the wiring diagram for the electronics.

Trying to spec everything out down the the last wire gauge/color and connector type so we can order everything then just sit down and wire it all up. Also contemplating a custom built box thats pre painted and punched with all of these holes.

Most likely will have to order everything before we decide on a final layout and can roughly lay things out on cardboard. Also, this box will be mounted on most likely a swinging arm on the right side of the brewing system enabling better control and wire management etc. Some pictures of that will be coming soon.

We already ordered 70 MIC connectors for most of the IO of various types. Next order is for the Brew Troller boards etc and the valves, about $700 worth of parts. Hoping to get a jump on this while we have some time off over the holidays.

Right now we could really use help in selecting circuit breakers, E-stop button, 20x switches, and general automation parts like DIN rails, distribution blocks etc.

blackheart

Well-Known Member

For example... Here is a 10A dual pole circuit breaker... we would connect the Hot and Neutral wires into one each.

http://www.automationdirect.com/adc...Series)/C_Curve_(0.5A-40A,_WMZT2Cxx)/WMZT2C10

Stil not sure what C curve and D curve is, if 10A is the right rating, and if we need additional breakers for the 24v AC and the 12v DC.

http://www.automationdirect.com/adc...Series)/C_Curve_(0.5A-40A,_WMZT2Cxx)/WMZT2C10

Stil not sure what C curve and D curve is, if 10A is the right rating, and if we need additional breakers for the 24v AC and the 12v DC.

dentid4h3d

New Member

blackheart, I've spoken with my boss and a couple of our engineers, they're more than willing to talk to you about building your panel for you once you have the desire spec ready.

as far as fuses you want to add as many as you feel comfortable. A single short taking out everything wont be a good thing. Remember though that most fuses/diodes wont be quyick enough to protect the troller so keep those relays in the middle!

blackheart

Well-Known Member

blackheart, I've spoken with my boss and a couple of our engineers, they're more than willing to talk to you about building your panel for you once you have the desire spec ready.

Thats awesome! I am specing out the panel now. Ordering parts like fuses and what not, doing a cardboard mock up, and then a digital drawing.

I visited a local coffee roaster (like a nano brewer for coffee) and they have a custom made industrial control panel. I plan on copying many things like the wire race ways and neat layout.

The industrial buttons are around $20 each for SPDT 3-pos switches, and we need about 20, which will most of the time be set on auto, so no point in waisting money there. I can get 20x SPDT micro switches for ~$20 shipped from ebay so it looks like we will go that route instead. The airplane switches we have now are pretty cool but only 2POS SPST.

Thinking about using something like a standard VESA 10cm mounting pattern on the rear of the enclosure so that in the future if we want to do something else with it other than mounting it on an arm their are tons of ready made brackets etc available.

Going to be placing the BT order this week. Need to sort out a few things with the wires and switches they sell before we place the order. Only a few more things to sort out before were are building the new electronics.

blackheart

Well-Known Member

Pulled the trigger this morning and bought all the brew troller stuff.

SKU Product Item price Quantity Total

SKU17559 BrewTroller Package Builder $0.00 1 $0.00

SKU17566 BrewTroller Core Package $107.46 1 $107.46

SKU17562 Gas Direct/Gas HERMS with Valve Control $93.98 1 $93.98

SKU17550 2 Pin Connector With Leads $0.69 20 $13.80

SKU17546 Mini DPDT Center Off Switch $1.25 20 $25.00

SKU17524 3 Pin Connector with Leads $0.79 36 $28.44

SKU17548 1/2" NPT Stainless Motorized Ball Valve $47.99 10 $479.90

SKU17571 Flashing Buzzer $8.99 1 $8.99

Also ordered circuit breakers for 120v, 24v and 12v lines as well as a 10cm DIN rail to mount them.

Then, from a third company, ordered a green LED 2pos selector switch as the ON/OFF switch and a E-stop mushroom kill switch.

Still in need of figuring out the wiring for all of the valves/sensors, internal wiring, terminal blocks, and 120AC plugs for pump output and 120v input

If you have any opinions on the following that would help,

- 3 wire cable for connecting valves/sensors to box

- AC receptacles for 4x ac outlets and 1 ac input connection.

- Terminal blocks, still undecided to go with screw terminals or DIN rail mounted terminals for everything.

SKU Product Item price Quantity Total

SKU17559 BrewTroller Package Builder $0.00 1 $0.00

SKU17566 BrewTroller Core Package $107.46 1 $107.46

SKU17562 Gas Direct/Gas HERMS with Valve Control $93.98 1 $93.98

SKU17550 2 Pin Connector With Leads $0.69 20 $13.80

SKU17546 Mini DPDT Center Off Switch $1.25 20 $25.00

SKU17524 3 Pin Connector with Leads $0.79 36 $28.44

SKU17548 1/2" NPT Stainless Motorized Ball Valve $47.99 10 $479.90

SKU17571 Flashing Buzzer $8.99 1 $8.99

Also ordered circuit breakers for 120v, 24v and 12v lines as well as a 10cm DIN rail to mount them.

Then, from a third company, ordered a green LED 2pos selector switch as the ON/OFF switch and a E-stop mushroom kill switch.

Still in need of figuring out the wiring for all of the valves/sensors, internal wiring, terminal blocks, and 120AC plugs for pump output and 120v input

If you have any opinions on the following that would help,

- 3 wire cable for connecting valves/sensors to box

- AC receptacles for 4x ac outlets and 1 ac input connection.

- Terminal blocks, still undecided to go with screw terminals or DIN rail mounted terminals for everything.

blackheart

Well-Known Member

Wow... Looked into the DIN terminal blocks... Not sure where we can just buy like 20 of them but they seem like they will really reduce the clutter and act as a nice distribution block for all of the connectors. Basically they are DIN mountable and have pathways for 1-4 connections with the option for the bottom one to be connected to the DIN rail for ground. Here is a link to the different versions of blocks. http://factorymation.info/catalog/fmcat_terminals.pdf

So I revised the electrical diagram to account for these. might be able to get away with using only a single DIN rail and dropping all the DIN terminals onto it. Going to have to wait until more parts come in before we know exactly what type and how many we need.

So I revised the electrical diagram to account for these. might be able to get away with using only a single DIN rail and dropping all the DIN terminals onto it. Going to have to wait until more parts come in before we know exactly what type and how many we need.

silverbrewer

Well-Known Member

I think the A and B curves you speak of on the circuit breakers are to do with the types of load they will be seeing, ie inductive or not. Some loads present a large surge current on initial start up and can trip the normal (fast) style breaker, (I had a small lathe that did this) so you fit the other type to stop this happening, at the detrement of outright speed of disconnection, so only do this when neccisary. If this is incorrect, or someone has the full details I am sure an expert will be along in a moment or two.

GC89

Well-Known Member

Stand looks great, I might have missed this but did you put up a link to lids you used? I didnt see any on walmart.com that looked the same and sears has a ton of lids. Whats the diameter of it?

blackheart

Well-Known Member

Stand looks great, I might have missed this but did you put up a link to lids you used? I didnt see any on walmart.com that looked the same and sears has a ton of lids. Whats the diameter of it?

The lids I ordered online through Sears... The link is a bit farther back... but searching Sears online you should find it. Its 12"

blackheart

Well-Known Member

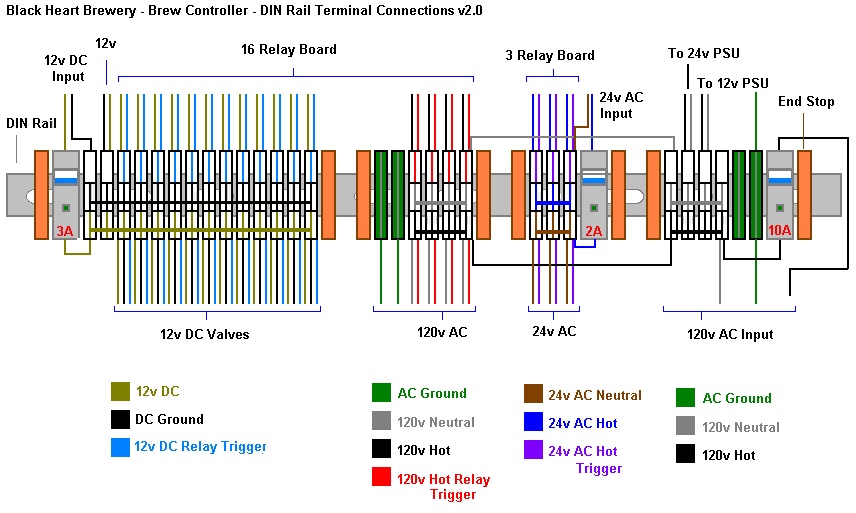

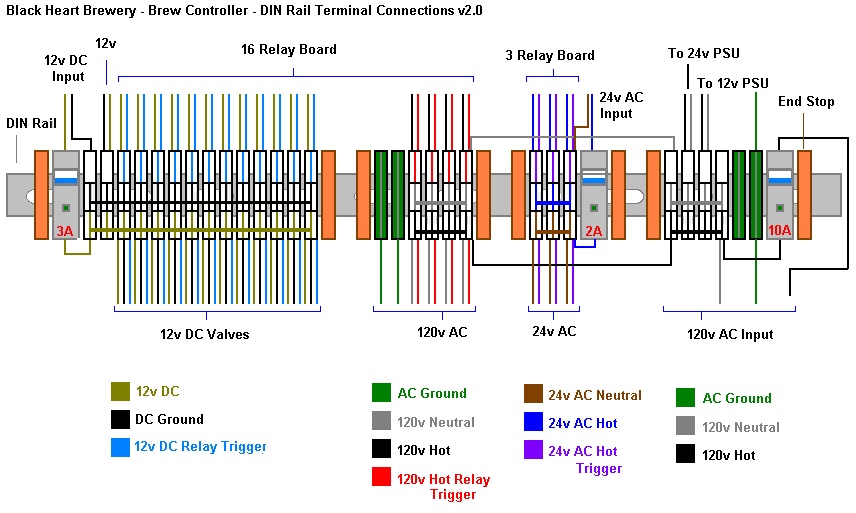

Well I was playing with paint.... and reading through the automation web sites... and figured out how to use a single type of DIN terminal for all of the connections. It is a 3 terminal connector, meaning it has 3 seperate pathways, each with an in and out connection, in one tall, 6mm wide, DIN terminal. We are also using a few ground terminals which have a metal foot to touch the DIN rail grounding its connectors to it. End stops clamp down and seperate sections of terminals and keep them from moving around.

Here is the wiring diagram revised as well as a close up of what wires are going in and out of the DIN rail terminals

Here is the wiring diagram revised as well as a close up of what wires are going in and out of the DIN rail terminals

blackheart

Well-Known Member

We have been working on some cool new ideas.... Started a new thread to get some feedback on some of them. Check it out here.

https://www.homebrewtalk.com/f51/automated-herms-rebuild-216077/#post2529358

https://www.homebrewtalk.com/f51/automated-herms-rebuild-216077/#post2529358

blackheart

Well-Known Member

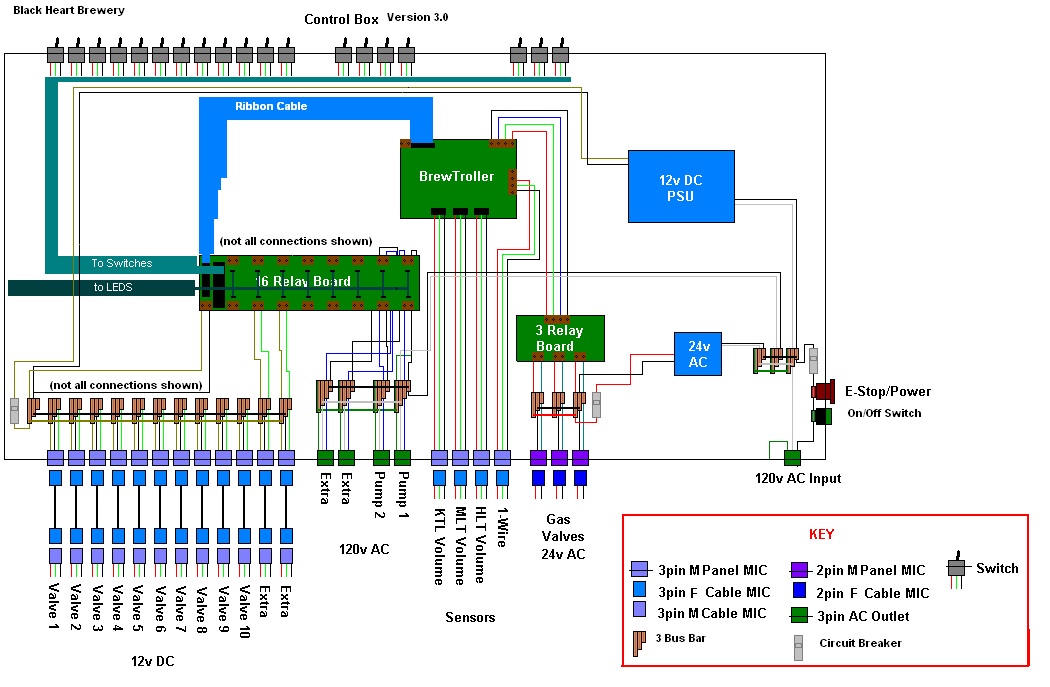

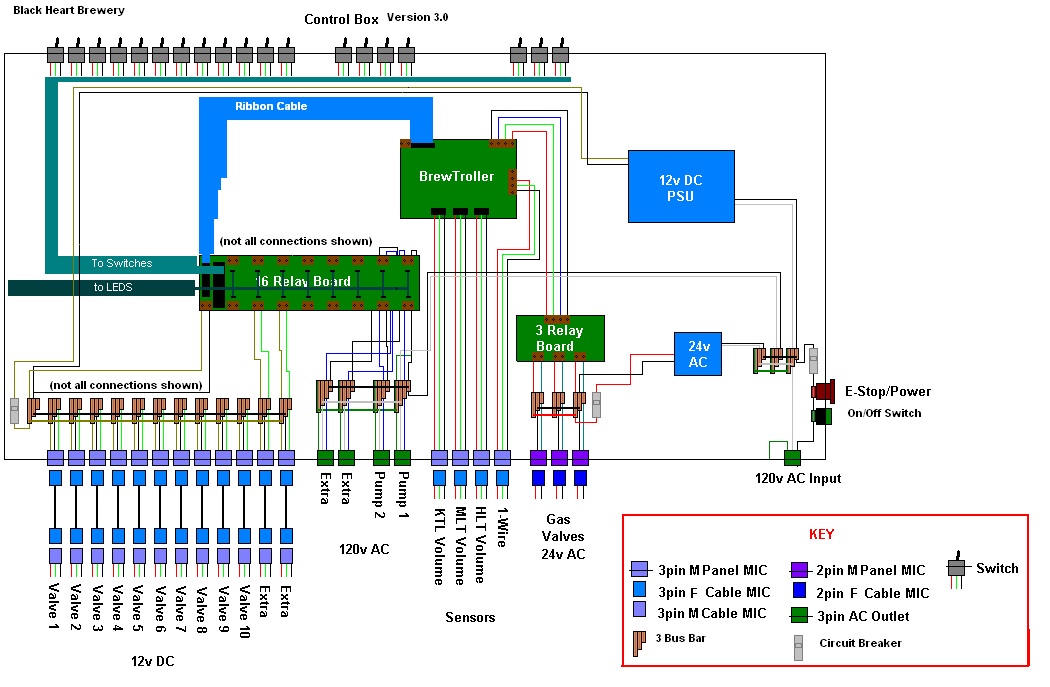

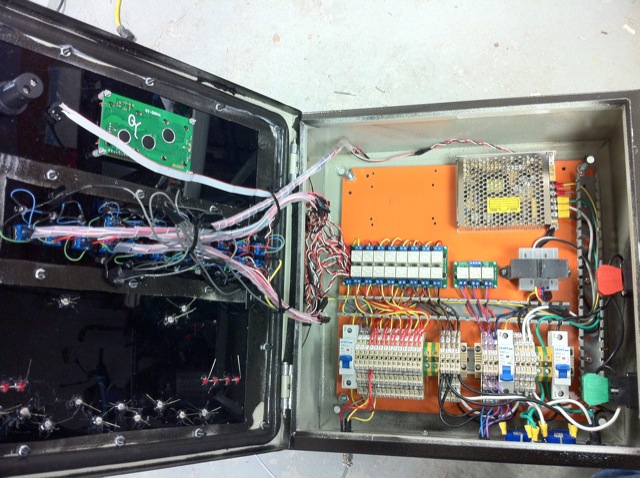

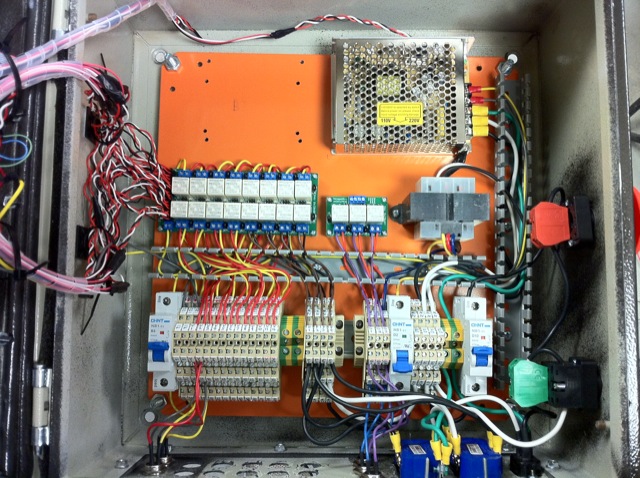

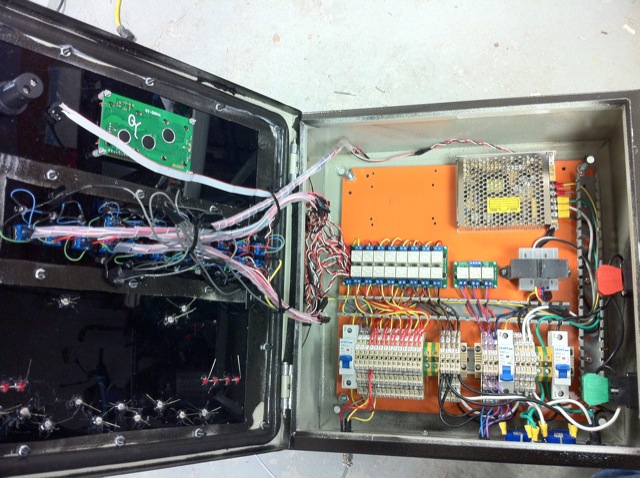

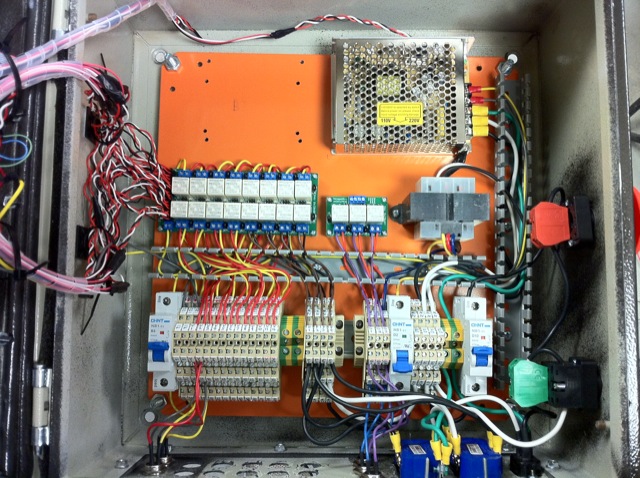

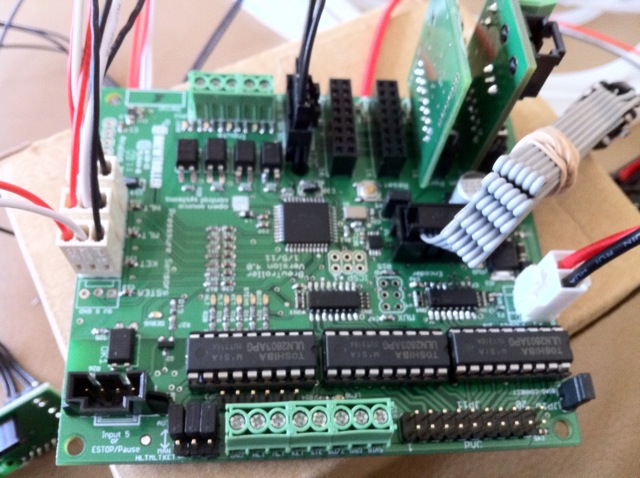

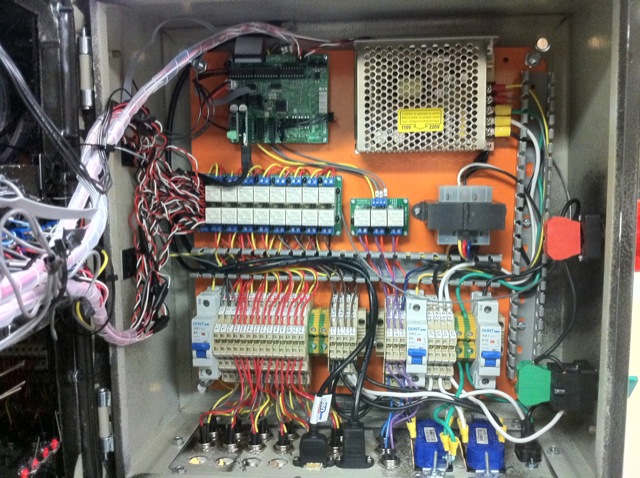

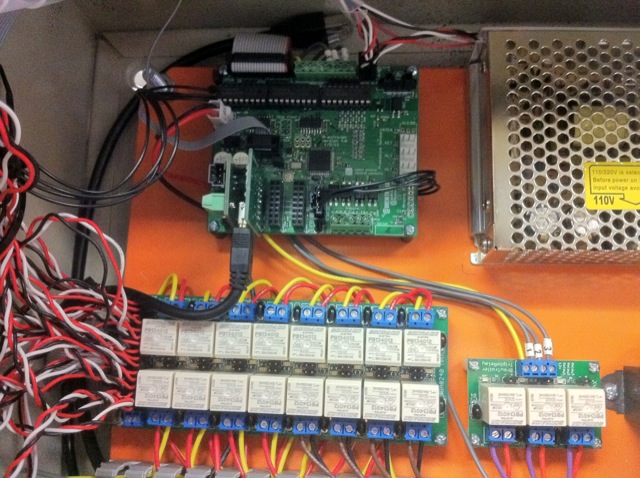

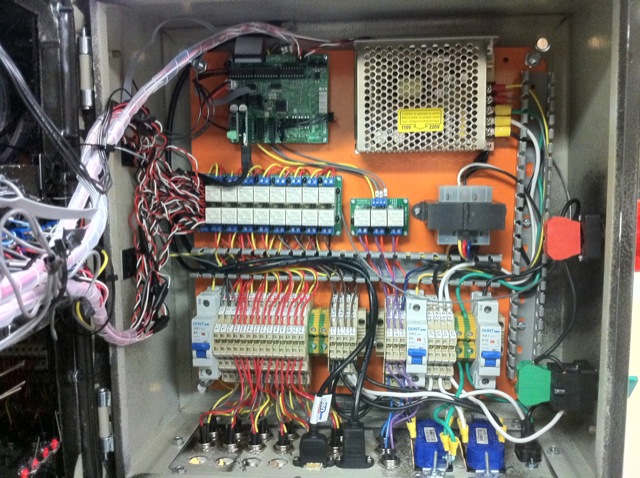

After a bunch of planning, ordering, and building we have made progress on the 2.0 version. The core of the system is the BrewTroller, soon to be 4.0. The main reason to go with them is they have a kick ass relay board with support for 16 devices including a manual/auto switch for each and an on board LED as well as a LED extension, both connected in line with the relay, if the LED is on, the relay is working.

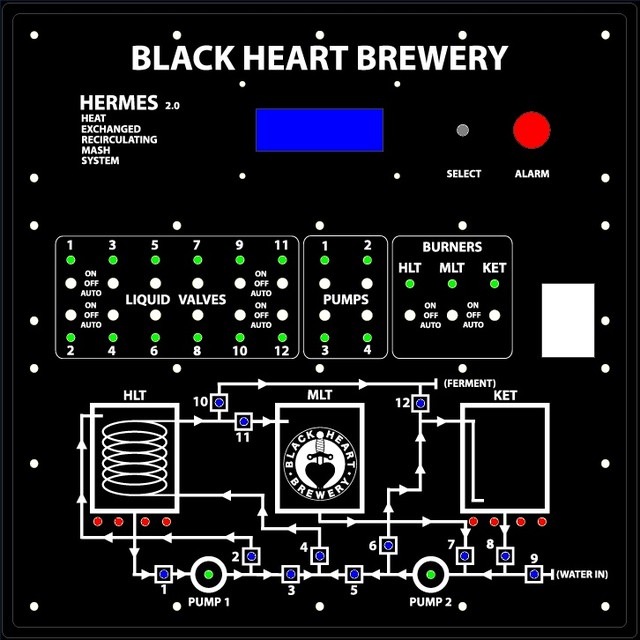

Here is the control panel we are having cut from black acrylic. It will arrive tomorrow.

You can see where all of the switches will go as well as a nice picture of the new system layout. Flip the switch for valve 5 and the light will turn green above the switch, on the diagram of the system valve 5 will also light up.

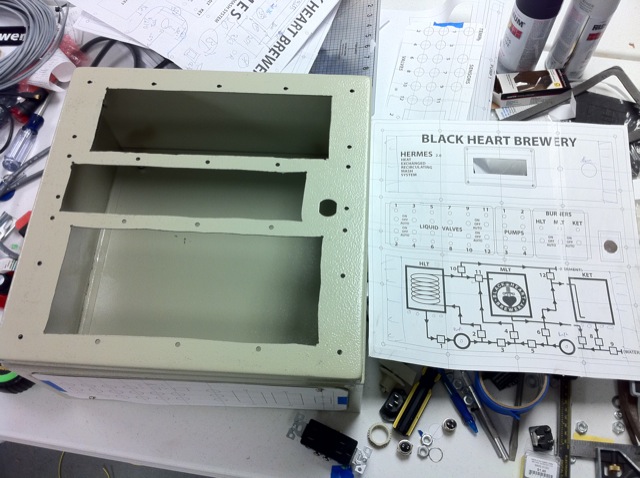

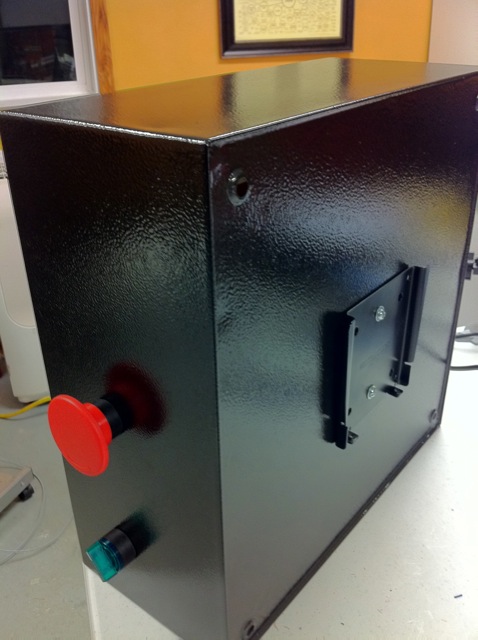

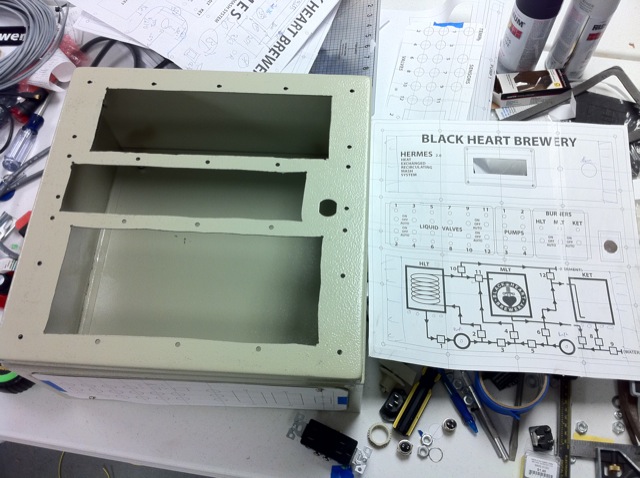

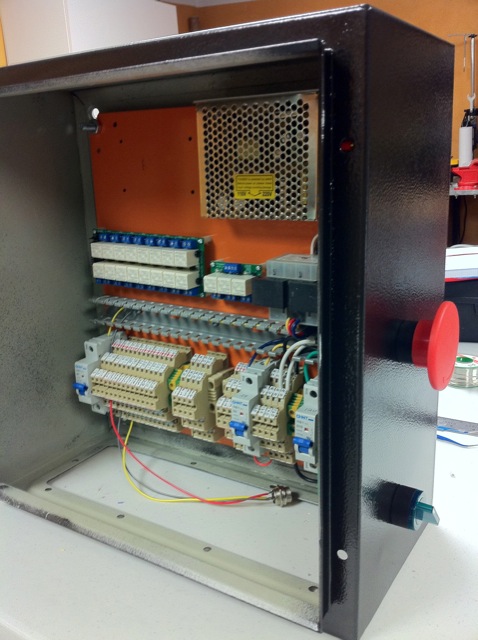

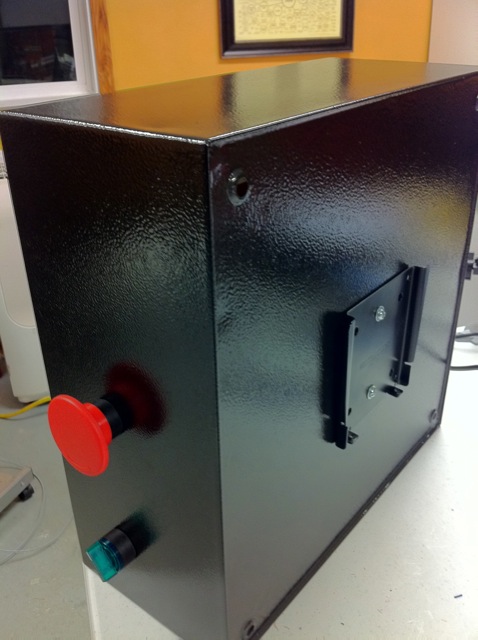

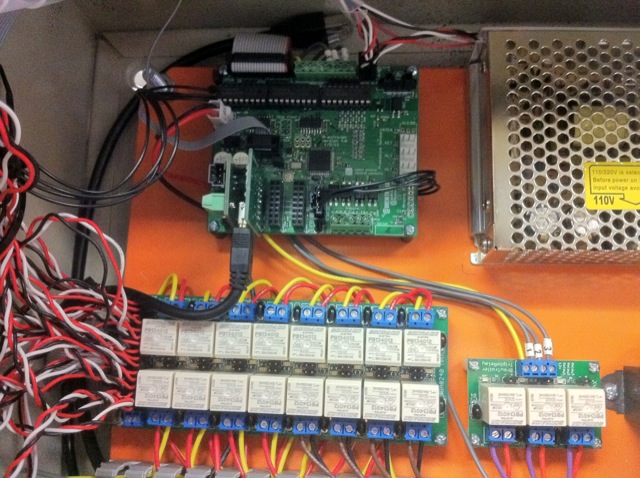

Here is the 16x16x6 box that we cut holes into to support the acrylic front panel.

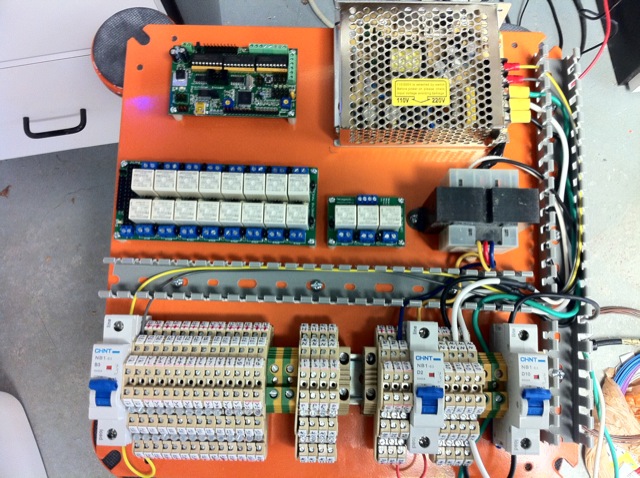

This piece is a steel plate that we mount all the electronics to. This screws into the box at the four corners enabling us to remove it to work on it.

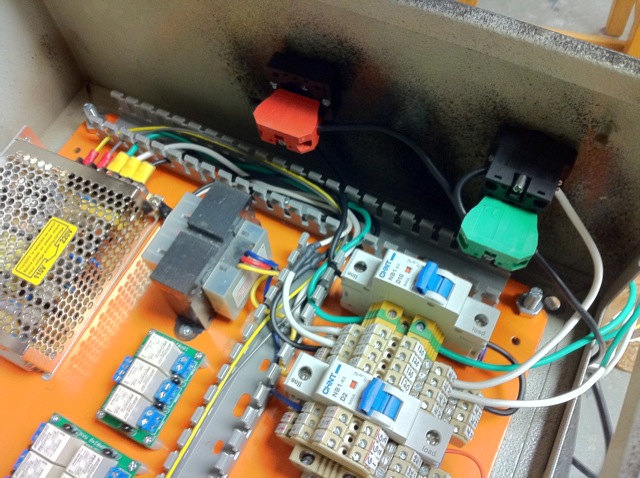

From top to bottom left to right we have the BrewTroller 3.0, 12v 3A PSU, 16 relay board, 3 relay board, 24v transformer, and at the bottom is all of the terminal connections for wires going in and out of the box.

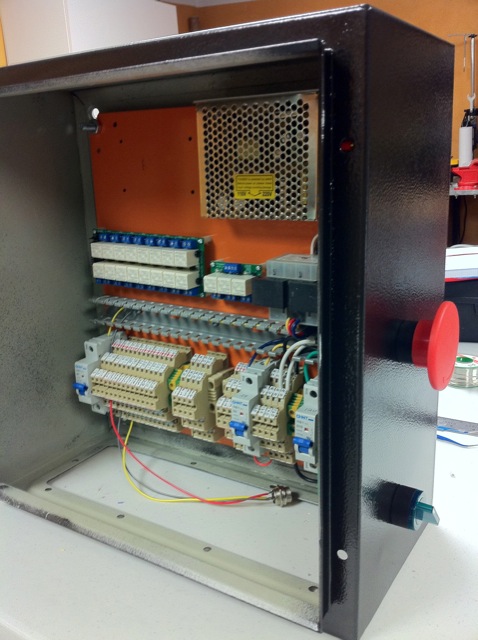

Here is everything mounted in the box, after painting it black of course, Two switches were added, the lower one is the main power switch, twist to turn the system on and it glows green when powered. The middle red mushroom switch is the E-stop switch which cuts power to the system instantly in the case of an emergency.

Here you can see some of the detail of the switch connections as well as the wire routing

In this picture you can see the slim wall mount VESA adaptor we will use to mount the box to an arm. This enables us to easily remove it or place it somewhere else in the future. VESA mounts, commonly used on TV's are fairly cheap and easy to install.

We used as few different style connectors as posible. The main one we used was the MIC connector, a kind of mini SLR connector thats locking and used on CB MIC's. Standard US outlets for the pumps. And we also added two custom cables, a USB connection to enable upgrades and logging, and this cool panel mount network cable.

Thats all the updates we have for now. We are working on a few different things at the same time here. We are finishing up the malt mill, wiring the control panel, adding a rotating arm to the brew system, and building a fermentor from a sanky keg.

More updates to follow shortly.

Here is the control panel we are having cut from black acrylic. It will arrive tomorrow.

You can see where all of the switches will go as well as a nice picture of the new system layout. Flip the switch for valve 5 and the light will turn green above the switch, on the diagram of the system valve 5 will also light up.

Here is the 16x16x6 box that we cut holes into to support the acrylic front panel.

This piece is a steel plate that we mount all the electronics to. This screws into the box at the four corners enabling us to remove it to work on it.

From top to bottom left to right we have the BrewTroller 3.0, 12v 3A PSU, 16 relay board, 3 relay board, 24v transformer, and at the bottom is all of the terminal connections for wires going in and out of the box.

Here is everything mounted in the box, after painting it black of course, Two switches were added, the lower one is the main power switch, twist to turn the system on and it glows green when powered. The middle red mushroom switch is the E-stop switch which cuts power to the system instantly in the case of an emergency.

Here you can see some of the detail of the switch connections as well as the wire routing

In this picture you can see the slim wall mount VESA adaptor we will use to mount the box to an arm. This enables us to easily remove it or place it somewhere else in the future. VESA mounts, commonly used on TV's are fairly cheap and easy to install.

We used as few different style connectors as posible. The main one we used was the MIC connector, a kind of mini SLR connector thats locking and used on CB MIC's. Standard US outlets for the pumps. And we also added two custom cables, a USB connection to enable upgrades and logging, and this cool panel mount network cable.

Thats all the updates we have for now. We are working on a few different things at the same time here. We are finishing up the malt mill, wiring the control panel, adding a rotating arm to the brew system, and building a fermentor from a sanky keg.

More updates to follow shortly.

blackheart

Well-Known Member

Last edited by a moderator:

TheFlyingBeer

Well-Known Member

Ah man, all kinds of awesomeness going on here. Looking great. The front panel is really slick. Sorry if you have already mentioned it but where did you get your faceplate made?

blackheart

Well-Known Member

Panel was made at ponoko.com

Last edited by a moderator:

Chuginator

Well-Known Member

- Joined

- Feb 14, 2011

- Messages

- 477

- Reaction score

- 61

I KNEW it would pay off to subscribe to this thread. I never knew Ponoko existed. That is amazing.

I'd love to see a nice real-world photo shot of that front panel!

Great work, guys - man, this thing is sickeningly slick. Love that automated ball valve @ 2:05 too. Very clean circuitry work inside that panel. Looking forward to more!

I'd love to see a nice real-world photo shot of that front panel!

Great work, guys - man, this thing is sickeningly slick. Love that automated ball valve @ 2:05 too. Very clean circuitry work inside that panel. Looking forward to more!

blackheart

Well-Known Member

More updates....

Our welder, Adam, has constructed a bolt on arm for the control box. He is coming over tonight to install it. Should make for interesting pictures tomorrow.

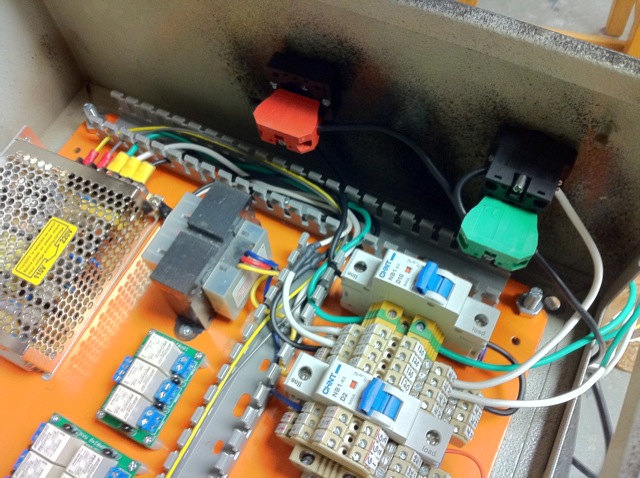

We have been wiring up a storm.... adding switches, wiring relays, etc etc. Only a few more connections to wire and we are ready to fire it up.

Here are some pictures of the progress.

Lets start off with whats changed on the front.... we now have the RGB led's working, Blue for auto, Green for manual ON, as well as the switches talking to the relays.

We also added a clear laser cut acrylic piece over the LCD to protect it as well as a chrome guitar knob for the encoder.

Lets have a look inside... You can see here that almost everything is wired, with the exception of the sensors, valve MIC connectors, Brew Troller board, and status LED's. All of the valve MIC connectors are soldered and ready to be installed, its just a slow process of pushing them into the terminals and screwing them down. Still the rest of the connections wont take long.

Here is a closer look. You can see all the different color coding for various voltages etc. These terminals make it much easier to find wires and keep everything organized.

As others suggested, we moved the Honeywell auto pilot controllers to a sub box. These talk to the valves with a 3 wire MIC connector ( pilot, main valve, ground) and the control box sends them a 24v signal to turn on with a 2 wire MIC connector. Spark plug cables are used to connect the ignitors up.

Here it is mounted to the center rear frame. Two tapped holes allow us to ground the controllers with minimal gaps in the box for liquid to enter. Controllers held in place with velcro.

On an unrelated note, we converted one of our spare kegs into a 10gal fermentor using the BrewersHardware.com sanky adaptor. Our first batch will be from the new system into this... should be interesting.

Our welder, Adam, has constructed a bolt on arm for the control box. He is coming over tonight to install it. Should make for interesting pictures tomorrow.

We have been wiring up a storm.... adding switches, wiring relays, etc etc. Only a few more connections to wire and we are ready to fire it up.

Here are some pictures of the progress.

Lets start off with whats changed on the front.... we now have the RGB led's working, Blue for auto, Green for manual ON, as well as the switches talking to the relays.

We also added a clear laser cut acrylic piece over the LCD to protect it as well as a chrome guitar knob for the encoder.

Lets have a look inside... You can see here that almost everything is wired, with the exception of the sensors, valve MIC connectors, Brew Troller board, and status LED's. All of the valve MIC connectors are soldered and ready to be installed, its just a slow process of pushing them into the terminals and screwing them down. Still the rest of the connections wont take long.

Here is a closer look. You can see all the different color coding for various voltages etc. These terminals make it much easier to find wires and keep everything organized.

As others suggested, we moved the Honeywell auto pilot controllers to a sub box. These talk to the valves with a 3 wire MIC connector ( pilot, main valve, ground) and the control box sends them a 24v signal to turn on with a 2 wire MIC connector. Spark plug cables are used to connect the ignitors up.

Here it is mounted to the center rear frame. Two tapped holes allow us to ground the controllers with minimal gaps in the box for liquid to enter. Controllers held in place with velcro.

On an unrelated note, we converted one of our spare kegs into a 10gal fermentor using the BrewersHardware.com sanky adaptor. Our first batch will be from the new system into this... should be interesting.

Chuginator

Well-Known Member

- Joined

- Feb 14, 2011

- Messages

- 477

- Reaction score

- 61

Awesome! Thanks for the pics!

blackheart

Well-Known Member

Our arm design had a last minute revision to avoid welding it directly to the frame, as a result it did not work correctly. Hopefully the solution is a simple addition of a piece of 2" tubing and a few bolts.

We also finished wiring and testing the valve connectors. These all work from switch to valve now. With the main valve manifold constructed we should be able to start connecting tubing again and begin testing and programing.

Put in another order for BT parts, two more valves, brewtroller 4.0 and a variety of connectors and wires are headed our way. This should be the last of the parts we need to get things together.

We also finished wiring and testing the valve connectors. These all work from switch to valve now. With the main valve manifold constructed we should be able to start connecting tubing again and begin testing and programing.

Put in another order for BT parts, two more valves, brewtroller 4.0 and a variety of connectors and wires are headed our way. This should be the last of the parts we need to get things together.

blackheart

Well-Known Member

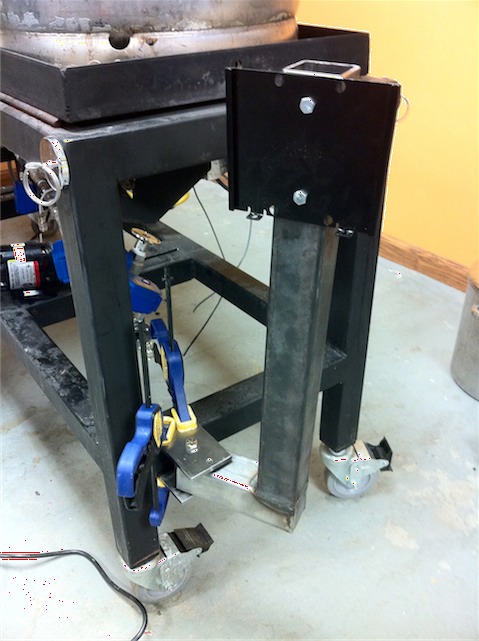

Here is the arm design. A flush VESA mount connect the box to the arm making it easy to remove. The arm clamps on via bolts. Needs to go up and out more. Working on a fix now.

blackheart

Well-Known Member

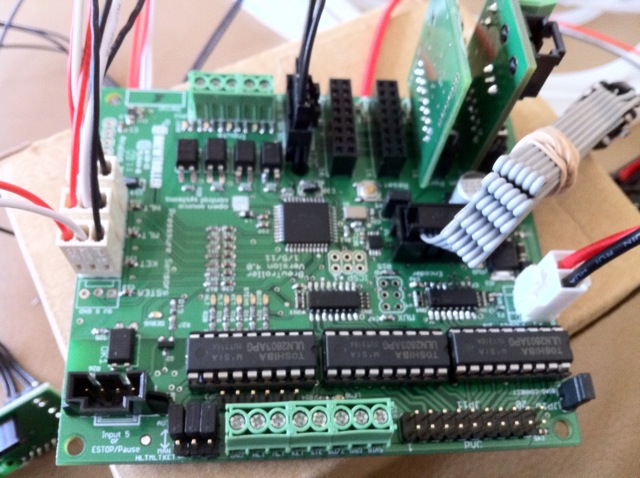

Our Brew Troller 4.0 arrived in the mail along with some more valves and wires we need to finish up the system.

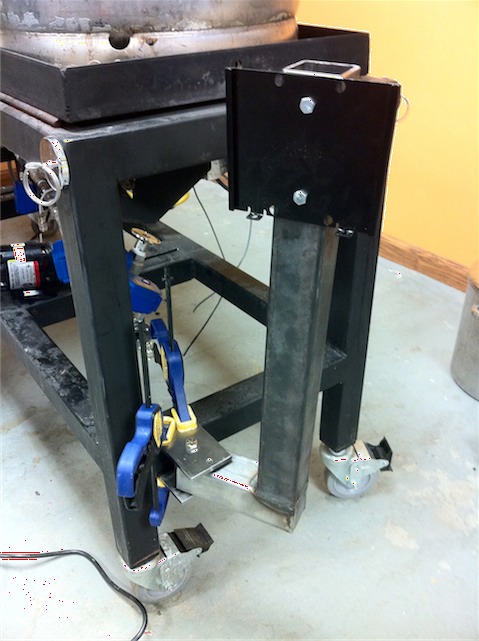

here is the BT 4.0 with the 1-wire board and the USB board plugged in.

We quickly popped it into our control box and got to work wiring it up.

A ribbon cable and a few other wires were needed to connect the two relay boards to the BT. The LCD is now a I2C connection so that was a much simpler single connector.

More pictures of the detailed wiring later when we are done, right now its about 95% complete.

We did fix our arm issues and now the arm is mounted and swings correctly.

With the arm mounted we also mounted the pump and valve manifold and started testing the control box. We are happy to report that the 9/12 valves we tested all worked successfully in manual mode. The 4 AC outlets also worked, two of which pumps are connected to. Then, we fired the burners, both worked flawlessly with the auto igniting pilot lights.

We have 2 more valve patch cables to wire and 3 more valves to test. After that we will be connecting the silicon tubing and TC fittings to reconnect the plumbing. We still have to figure out how we will be wiring the temperature probes, other than that we should be ready for a full scale test this weekend. Lots more pics coming soon.

here is the BT 4.0 with the 1-wire board and the USB board plugged in.

We quickly popped it into our control box and got to work wiring it up.

A ribbon cable and a few other wires were needed to connect the two relay boards to the BT. The LCD is now a I2C connection so that was a much simpler single connector.

More pictures of the detailed wiring later when we are done, right now its about 95% complete.

We did fix our arm issues and now the arm is mounted and swings correctly.

With the arm mounted we also mounted the pump and valve manifold and started testing the control box. We are happy to report that the 9/12 valves we tested all worked successfully in manual mode. The 4 AC outlets also worked, two of which pumps are connected to. Then, we fired the burners, both worked flawlessly with the auto igniting pilot lights.

We have 2 more valve patch cables to wire and 3 more valves to test. After that we will be connecting the silicon tubing and TC fittings to reconnect the plumbing. We still have to figure out how we will be wiring the temperature probes, other than that we should be ready for a full scale test this weekend. Lots more pics coming soon.

Chuginator

Well-Known Member

- Joined

- Feb 14, 2011

- Messages

- 477

- Reaction score

- 61

You're a bad influence!!

Similar threads

- Replies

- 0

- Views

- 385

- Replies

- 0

- Views

- 349

- Replies

- 5

- Views

- 727