I've dithered back and forth about how to control my boil element and eventually closed my eyes and just chose the higher end option, the Auber EBIAB kit: https://www.auberins.com/index.php?main_page=product_info&cPath=64_66&products_id=678 The base price is $370, plus or minus depending on what you want.

I've been amazed at what these panels cost, but this was the most cost-effective option for me especially if I want to try some variations. I'm also doing a RIMS system but it's running separately from the Auber kit. FWIW, I'm trying to do LODO brewing so this is part of a larger set of equipment including a stainless counterflow chiller.

I'm also going to implement BobbyM's steam condenser as part of this, which is one reason why I'm going to electric brewing--so I can brew in the garage in the winter without having to exhaust steam with a fan and provide makeup air and use a propane heater and yada, yada, yada.

***********

Can the average person put one of these together? I'm going to say probably not. I've done some wiring in my past, wired up a PID I use to control temp for an alloy pot, but this one was a big challenge. Thanks to all who helped, especially @augiedoggy.

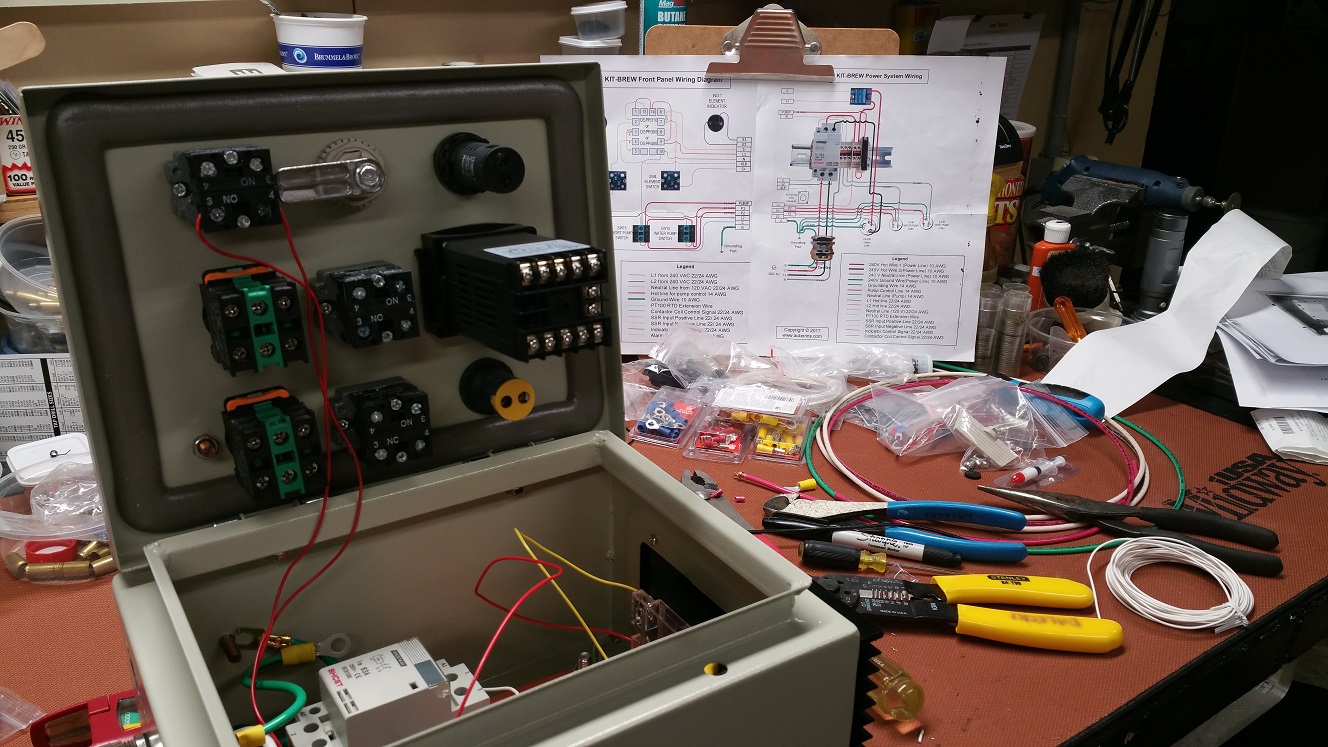

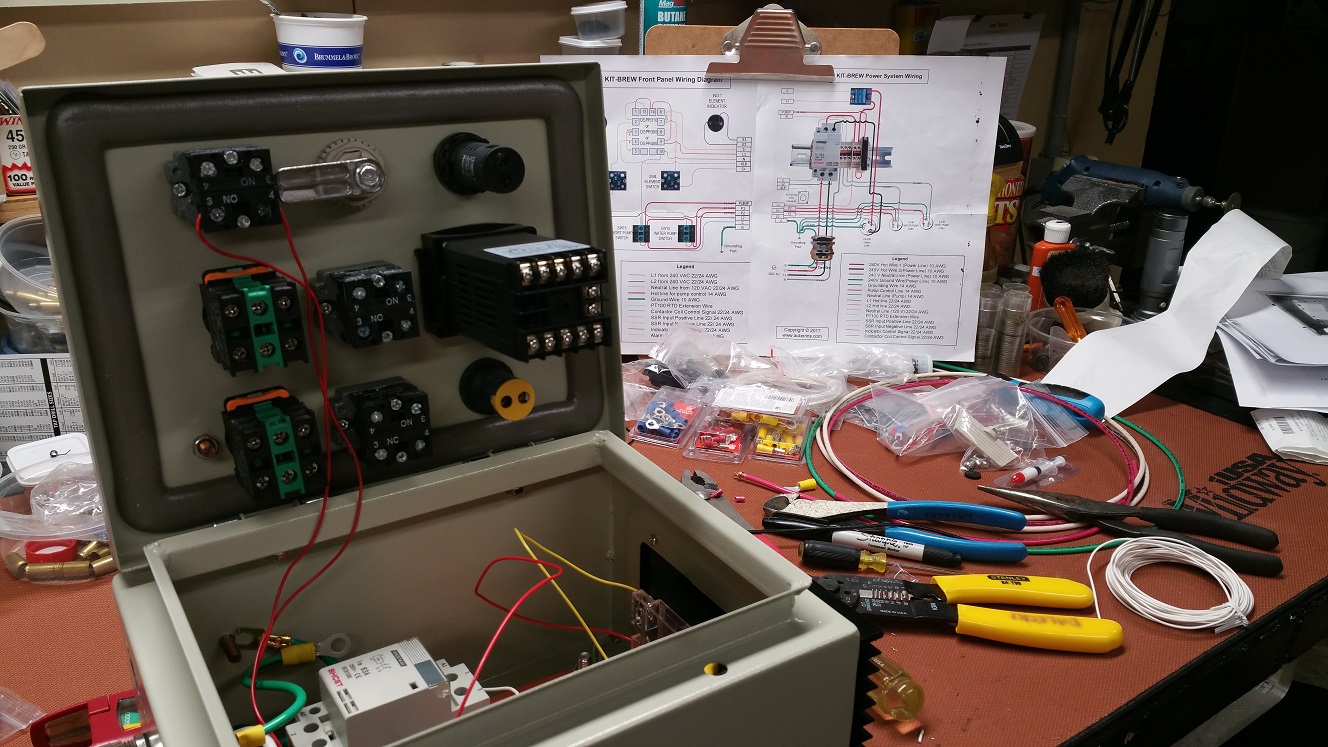

There are no instructions for putting this thing together other than a wiring diagram. It's actually a pretty clear diagram but how exactly one should terminate wires isn't exactly clear. I ended up using a lot of ring and spade terminals which clean things up a bit, but necessitated one extra run to the home store when I ran out.

Another example is a couple of jumpers that were included. No indication where they go, except that after VERY close inspection of the wiring diagrams, it appeared they went on top of the terminal blocks. Pushed them in and there we were. But it was not obvious to a first-timer.

What also makes it difficult is that there are clearly items that should be installed in a certain order or it becomes crowded and hard to add wires. For example, I didn't screw down the SSR to the heat sink until well along and it was hard to get my hands and such in there. What I should have done was do this first, screw the SSR to the heat sink (using thermal paste), add the wires, feed the wires through the hole in the case, then attach the heat sink.

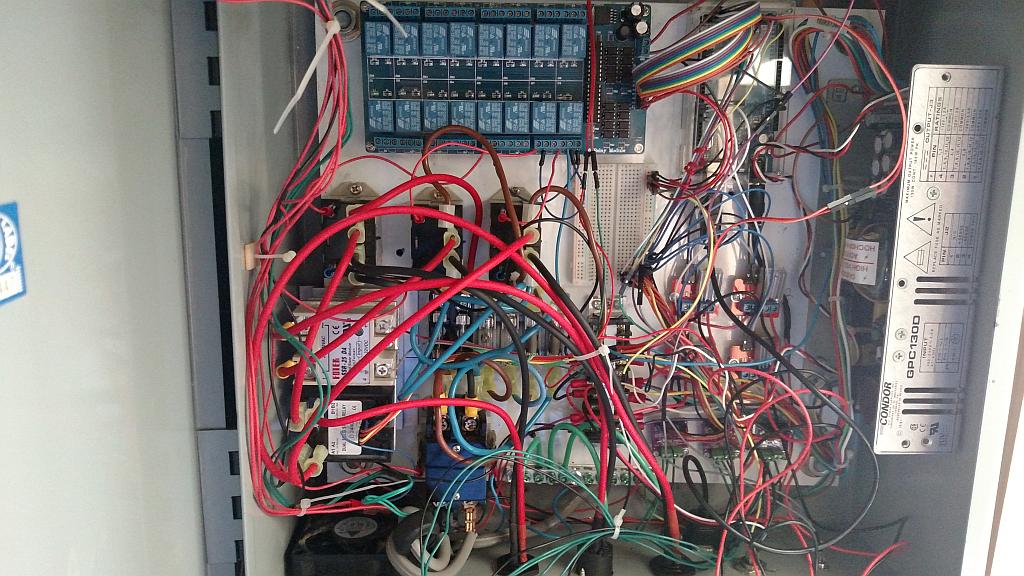

I've posted a few pics showing the process and the end result. I'll tie off some of the wires with zip ties and perhaps a cable wrap. Once it was done I double checked all the connections and that the wires were the right gauge and going to the right places.

********

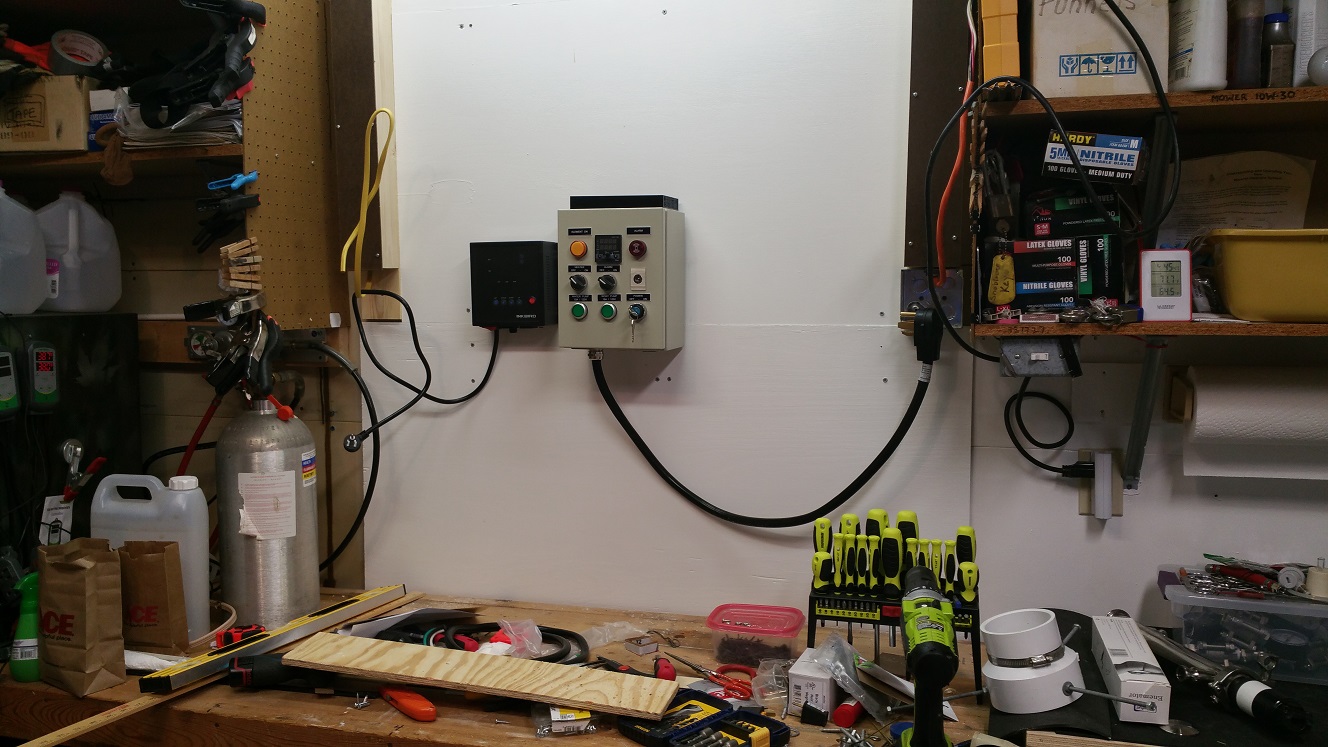

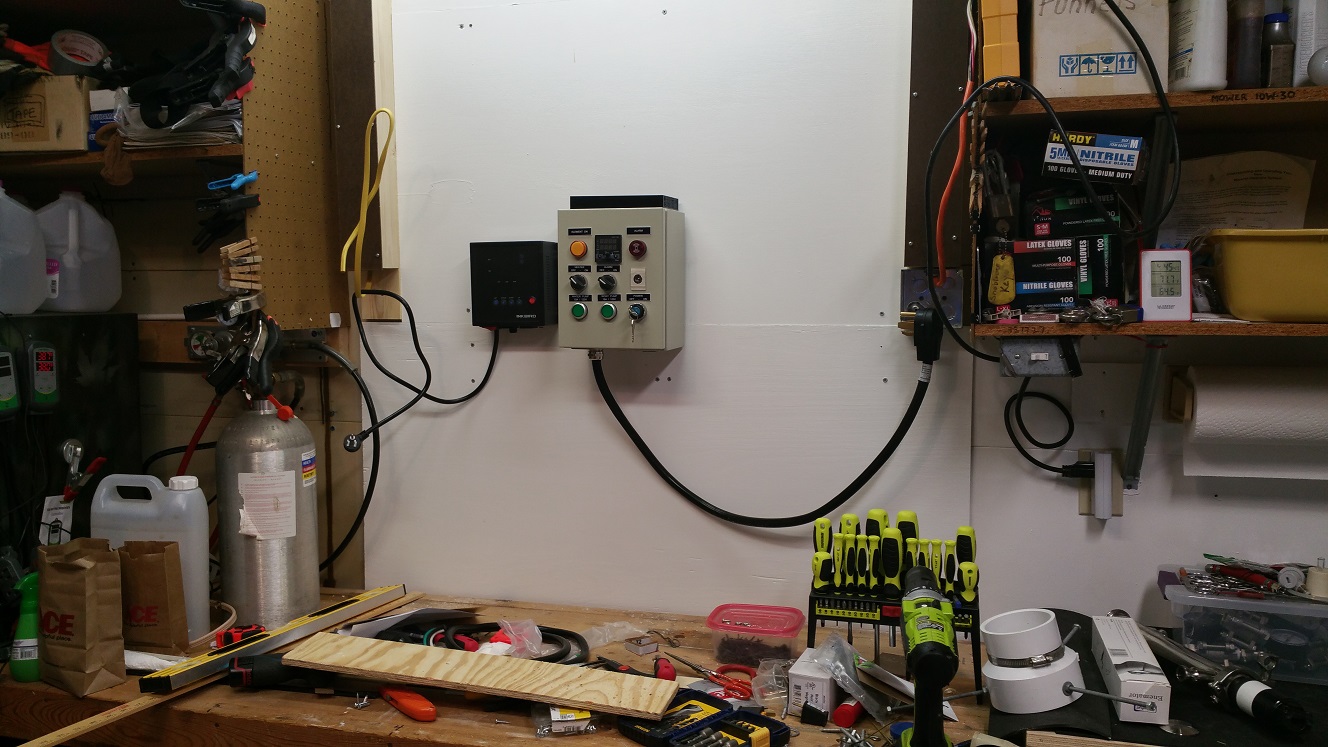

The wiring in the garage is not complete; I have an electrician friend who's helping with the final connections to the main panel as well as the sub panel we installed in the garage, but he can't get back to finish until next week. So you see where the panels will plug in, just no receptacles as of yet.

Not sure exactly how I'm going to arrange things. I might just start with kettles on the workbench, but eventually I'll bet I'm going to build some sort of brew sculpture once I figure out how all this works together.

I'm crossing my fingers that this all will work but until the electricity is connected, I'm just looking at it. If you see anything that looks amiss, please sing out!

I've been amazed at what these panels cost, but this was the most cost-effective option for me especially if I want to try some variations. I'm also doing a RIMS system but it's running separately from the Auber kit. FWIW, I'm trying to do LODO brewing so this is part of a larger set of equipment including a stainless counterflow chiller.

I'm also going to implement BobbyM's steam condenser as part of this, which is one reason why I'm going to electric brewing--so I can brew in the garage in the winter without having to exhaust steam with a fan and provide makeup air and use a propane heater and yada, yada, yada.

***********

Can the average person put one of these together? I'm going to say probably not. I've done some wiring in my past, wired up a PID I use to control temp for an alloy pot, but this one was a big challenge. Thanks to all who helped, especially @augiedoggy.

There are no instructions for putting this thing together other than a wiring diagram. It's actually a pretty clear diagram but how exactly one should terminate wires isn't exactly clear. I ended up using a lot of ring and spade terminals which clean things up a bit, but necessitated one extra run to the home store when I ran out.

Another example is a couple of jumpers that were included. No indication where they go, except that after VERY close inspection of the wiring diagrams, it appeared they went on top of the terminal blocks. Pushed them in and there we were. But it was not obvious to a first-timer.

What also makes it difficult is that there are clearly items that should be installed in a certain order or it becomes crowded and hard to add wires. For example, I didn't screw down the SSR to the heat sink until well along and it was hard to get my hands and such in there. What I should have done was do this first, screw the SSR to the heat sink (using thermal paste), add the wires, feed the wires through the hole in the case, then attach the heat sink.

I've posted a few pics showing the process and the end result. I'll tie off some of the wires with zip ties and perhaps a cable wrap. Once it was done I double checked all the connections and that the wires were the right gauge and going to the right places.

********

The wiring in the garage is not complete; I have an electrician friend who's helping with the final connections to the main panel as well as the sub panel we installed in the garage, but he can't get back to finish until next week. So you see where the panels will plug in, just no receptacles as of yet.

Not sure exactly how I'm going to arrange things. I might just start with kettles on the workbench, but eventually I'll bet I'm going to build some sort of brew sculpture once I figure out how all this works together.

I'm crossing my fingers that this all will work but until the electricity is connected, I'm just looking at it. If you see anything that looks amiss, please sing out!

Last edited:

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)