BowAholic

Well-Known Member

I'm using mine right now...  brewing an American pale/amber ale...

brewing an American pale/amber ale...

Thanks guys! I really didn't see the point myself if it was going to be used for the boil. Just wanting to try and do this right the first time!

Probably the oilfield in me coming out, but I would say if your having doubts just go ahead and drill the hole and put a blind plug in it or a small valve, you can always use it for whatever you want later.

Oh and as for drilling holes, DON'T! Go to harbor freight or something and get one of those cheap conduit punches, about 1,000,000 times easier.

I want to all grain and I want to go ahead and buy big enough now so I don't have to buy again later. I have a 10 gal cooler mash tun and looking at a 15 gal. Brew pot and HLT.... I want the thermometer and sight glass on the HTL but just didn't see the need for it on my boil pot.

I'd put a sight glass on the boil pot. Just my 2 cents. But I like to know what I've got in the pot. If I need to keep sparging or boil longer. I think you could do without the thermometer, but I think you might wish you had the sight glass.

Kettle screen on the valve in the boil pot?? Thoughts...

I wondered about that.... That is why I want one on the HTL to keep up with how much was going in. I take it that doesn't always work?

My thought is if it's on the boil kettle, you really don't need one on the HLT. You can stop the sparge when you reach your desired level. To me it would be more beneficial on the boil kettle.

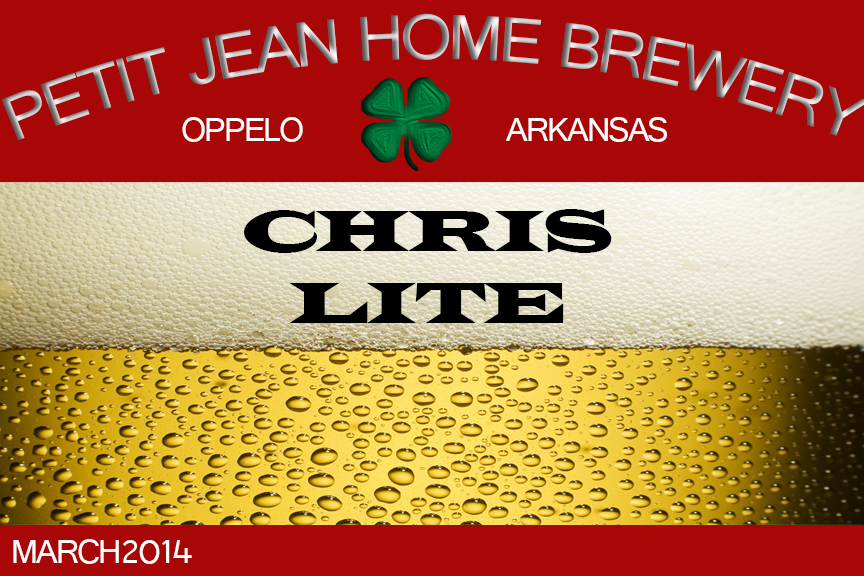

Ok... Do any of y'all make or have labels for your bottled beer??

Ok... Do any of y'all make or have labels for your bottled beer??

dang... looking at all of those different beers made me thirsty!

Bob

View attachment 268483

My 1st... Cheap free one just playing around. I have been using the sharpe. Just playing around and wondered what you guys did.

View attachment 268710

Still playin'...

cool... I guess I'm going to have to learn how to do this too... :rockin:

Labelizer.com. It's easy and has some freebies,,,

My new 12x24 brew shed is up, all they have to do is come back and install the 6ft bay door on the end! I have to get my electrical service upgraded from 125 amp to 200, and run the plumbing and electrical out there. Also wanted to build some work benches and places to store bottles. Really excited about it, but a little bummed I had to put my electric brewery build on hold.

Having a Smithwhick's tonight, cheers!

Sweet!!! @BowAholic

thanks! I had no idea how easy it could be...

Bob