I have used my 6.5 Anvil for 26 batches now (it is the first generation purchased back last July).

I have only had issues with the support ring when I have not paid attention to the feet on the malt basket. One of the firs things I did with the ring was to gently stretch it so that the gap in the ring is about 1.5 to 2 inches wide. It now takes a bit of effort to push the ring in place, but it has not come out without my being stupid about it.

The silicone gasket is definitely a PITA. The silicone ring will actually hold into the rim of the top if you carefully press it in along the edge, for a while at least. Enough heating and cooling cycles and it pops out again. When it does, I just hang it up from the handle and wait until everything is cleaned up and cool before pressing it back in place. It is then good for another couple of brews before falling out again.

I have had no issues with the controller. I have found that I can ramp the temperature up to get to strike temp faster and then drop the power to around 55% to 60% at 240V and it holds temperature really well. I go about 10% higher at 120V.

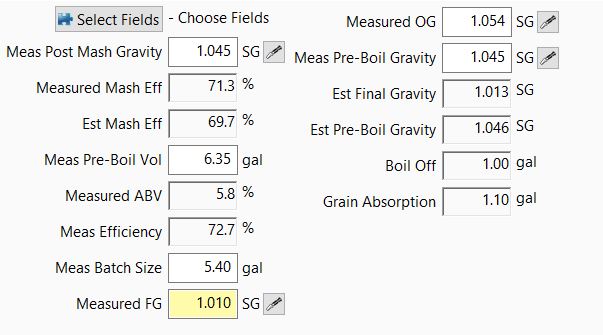

It is really a BIAB system as are most of the all-in-ones. In fact, I have stopped sparging on most recipes and just go full volume mash. It saves time, is more predictable and reproducible this way. Now I sparge only for high gravity beers. I went to using my BIAB bag to line the mash pipe after a few brews mostly for the ability to crush a bit finer to get better efficiency and for a faster clean-up of the malt basket. THAT was a PITA, getting those grain particles out of the crevices where the bottom piece fit the walls of the mash basket. The bag allowed me to push the grind quality a bit finer without worrying about overloading the wort with grain debris.

I measured the dead space several times before I ran the system for the first time. Setting the unit flat, I ended up with 1.6 liters (1.7 qts) of wort left in the unit with the drainage arm aimed straight to the bottom of the kettle. Now, I place a block of wood under the unit to tip it forward when I am draining the wort and I end up with around 700 ml (0.75 qts) left in the kettle.

I have a SS chiller which is about two and a half times the length of the one supplied with the Anvil. The difference in chilling between the two of them is around 5 minutes to go from near boiling down to around 60F, less than 15 minutes with my chiller vs just under 20 minutes with the Anvil chiller. I guess a lot is based upon your tap water temperature and I have a deep well with the temperature barely creeping into the mid-50's in the heat of summer.

From my stove top BIAB process, I am finding the process is about the same with my total time from dough in to clean up relatively the same as before. It really comes down to being able to have the same system in the winter when I brew indoors to outdoors in the spring and early fall. It was a PITA to drag out the propane and burner, set everything up and then have to play around with the flame and boil off rate to get the outdoor brews to mimic the indoor brews. The Anvil is pretty consistent for me both indoors and out.

My process did change for hop additions. I used to just throw the hops into the kettle with BIAB. With the Anvil, I could get away with that for lightly hopped recipes but not with anything requiring a good amount of hops. I went to a hop sack and then purchased a hop basket. That caused me to make a slight adjustment up in my hops to replicate the bitterness I was getting with 'free range hopping'.

Maybe it is because I have a strong process background, but it took only a little work and thinking (that part hurt) to figure out how to get the system to reproduce close to what I was getting previously at about the same efficiencies.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)