jonp9576

Well-Known Member

wow, great information. i am going to try that in the next couple days.

Straight Argon is fine. Prep the weld zone with a new scotch brite wheel if there is scale/dirt to remove or clean... the important thing is the area is clean. 2% Thoriated Tungsten for your tig torch and you should be ready... just be carefull of warpage from to much heat in one area of the fitting being welded. Don't continuously weld a bead.. skip weld until the fitting is welded all the way around. I don't know if your going to gas back the inside of the keg with Argon. If not. use some Solar Flux B on the joints on the inside.

He is welding with a MIG setup. QUOTE]

He asked a question about Tig welding so I gave him info for that..Here's his question..

i am using stainless filler. i think it is 308. i'll try to get ahold of some 316. We run a compressed gas and welding supply shop here so i should be able to get it fairly quickly.

how do i clean the stainless before and after i weld it. i've read that regular samd baber s bad, and the same goes for grinding wheels.

i have a stainless wire wheel coming. is there anything else i need?

about gas...i was using 75/25 argon co2 for steel. for stainless i was told 100% argon so thats what i've been using. is there anything else i should try other than 100% argon? i can make just about any mixture you can think of since we sell it all here and i can blend it myself.QUOTE]

i am using a mig machine, not a tig machine. we only stock 030 stainless wire, but i can get any size. i'll order some 023 and see how that works out for me

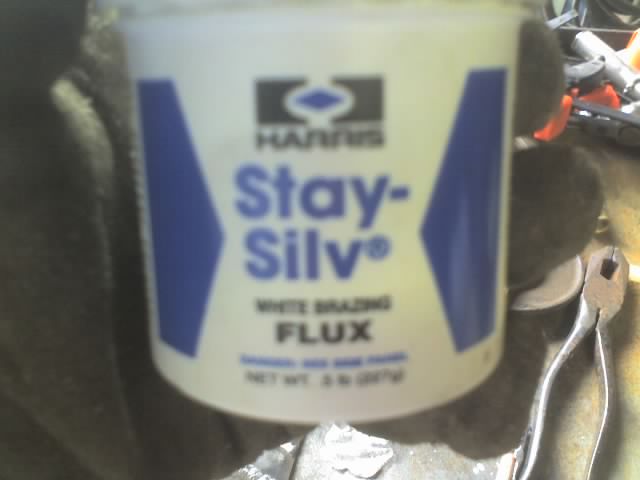

Make a thick slurry of the flux, paint it on the opposite side of the weld out to 1/2" from weld area to protect the adjacent metal. Instructions on can call for alcohol but water works well too, about 1 drop to the spoonfull works for a start. After welding the flux will fuse together and leave a glassy surface that will come off with a stainless brush on a 4" grinder. When making water tight welds check to make sure there are no flux pockets in the weld to break out and cause a leak, drill out the pocket and make a pass over the hole.

I am now retired, but stayed under a hood for 30 years, ASME pressure vessel certified.Im a welder by trade

I am now retired, but stayed under a hood for 30 years, ASME pressure vessel certified.

and it is very common to mix solar flux with water or denathered alcohol.

Im a welder by trade, and I never heard of mixing the flux with water. In fact, water will cause welding defects such as porosity, and cause leaks. If your using solar flux type B for welding stainless, go out and buy a product called HEET. They sell it in the automotive section in wal-mart. HEET is what your supposed to mix the flux with.

I think HEET is just a form of alcohol and I believe that if you use it in welding, the purpose would be to help drive out any water moisture.

ok sounds good. i'll try out the helium mix and some smaller wire

we own the welding supply shop. i'll make the mix. what are the %

sounds good. i'll make that mix up this weekend and give it a try. i have an old stainless liquid oxygen container i am practicing on.

if i were to make the conical, i would buy one of these hoppers that are apways posted on here and weld it to the bottom of the open cylinder. if i do that, should i weld the inside so its cleanest on the inside, or should i weld from the outside. i was thinking the inside. do you get what i'm asking?

ok, so lots more practice before i even consider mig welding the fermenter.

and i will look for the solar B flux. i have seen it in our shop before i know we get it in once in a while.

Also I should tell you solar flux isnt cheap, at $45 for a one pound can, but it goes a long way, as you only need a little at a time. Also a product called heet.

By the way, even though I weld for a living, I would love to work in a welding supply store. I would never have any money each payday, it would go all back into the store for equipment, and gadgets!