EyeofdaHawk

Well-Known Member

Howdy peeps

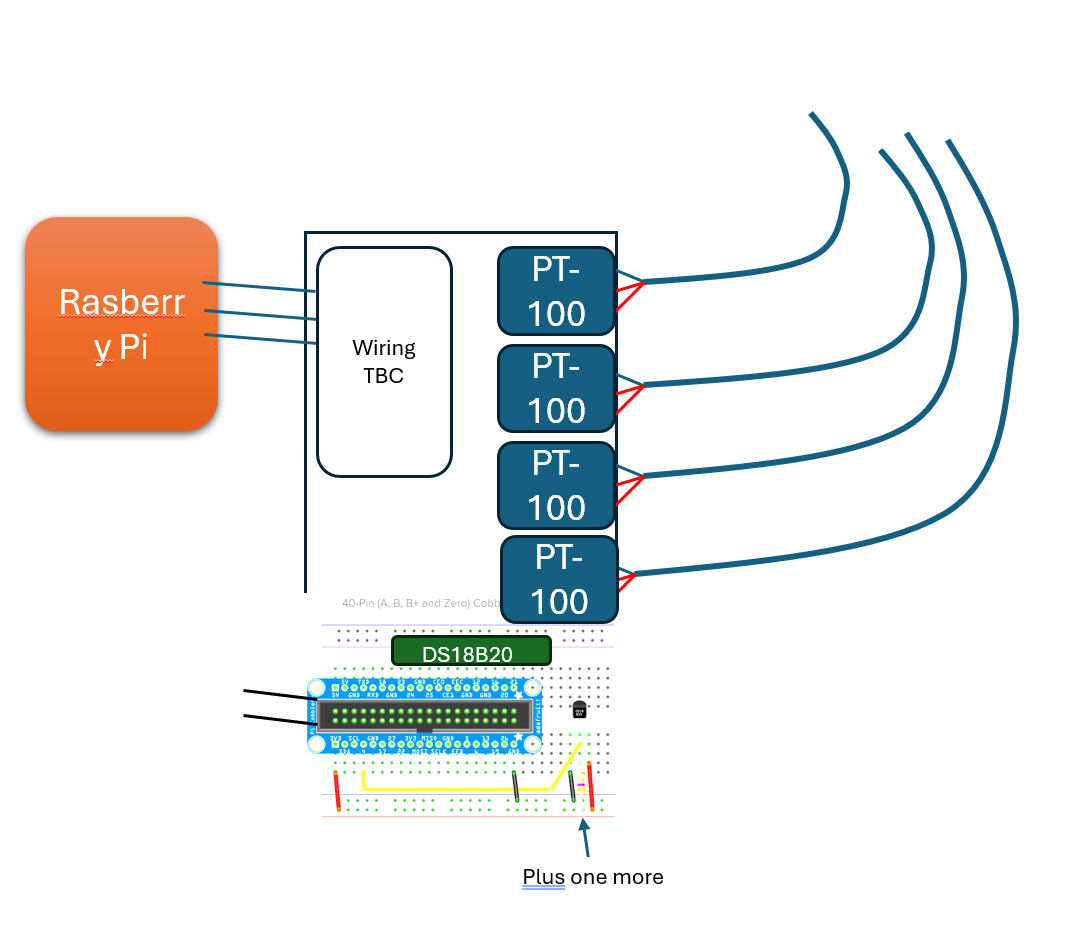

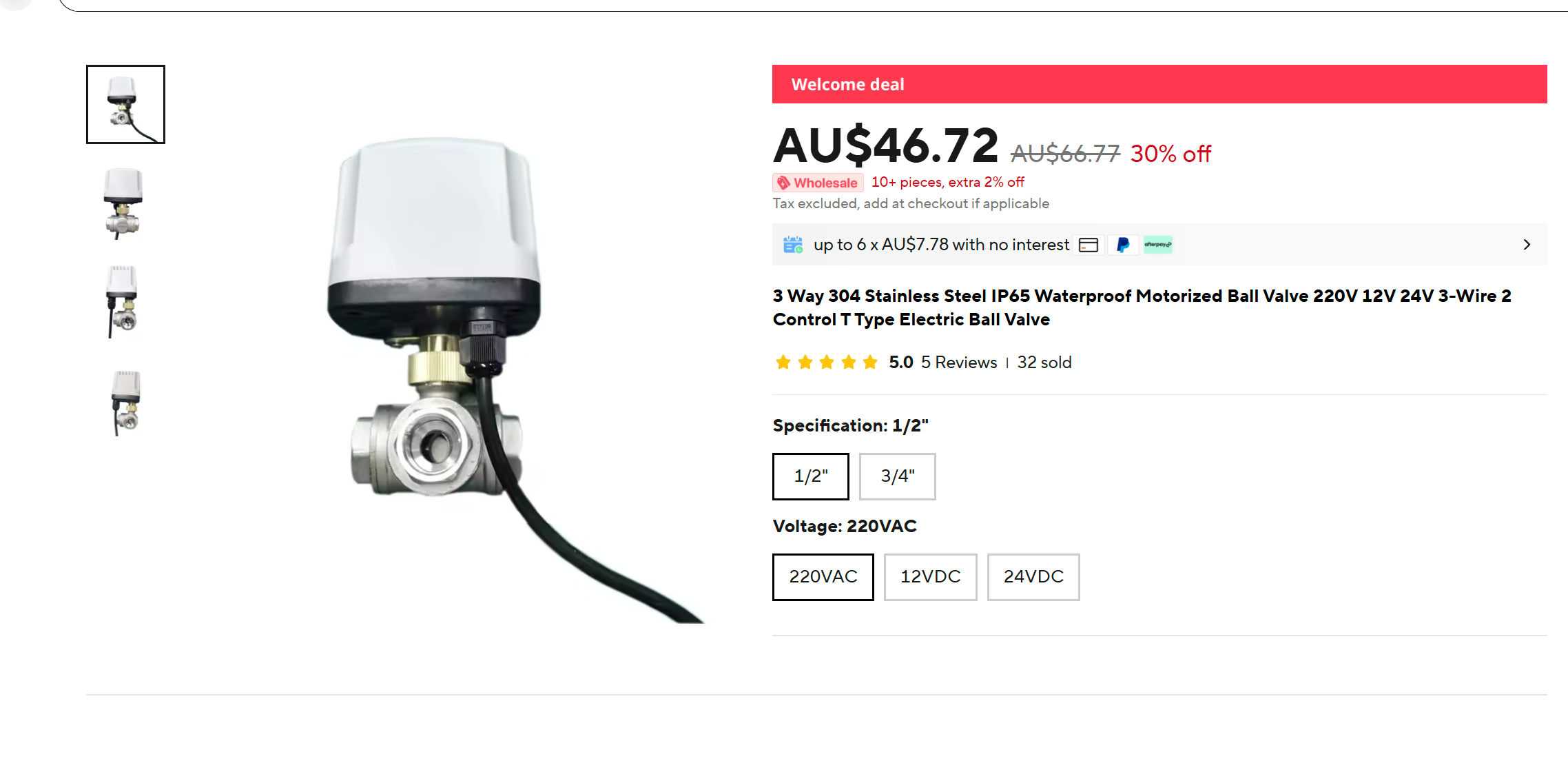

I'm keen to know if i can use adjust my existing system to add in automation (via Rasberry Pi - maybe craftbeerpi). I understand it would require essentially a new control board and that's no issue. What i wonder is can i use the existing SSR, the PIDs, etc. I plan on getting a bunch of these so i can remotely control the valves.

Main question is can i control the PIDs, and thus the power to the elements (2x 6kw - 240v), or would i need to bypass them? I also wonder if i could plug into the 'auto' side of the pumps.

Effectively i need a new project and this is one i've been mulling over for some time.

Cheers

Hawk

I'm keen to know if i can use adjust my existing system to add in automation (via Rasberry Pi - maybe craftbeerpi). I understand it would require essentially a new control board and that's no issue. What i wonder is can i use the existing SSR, the PIDs, etc. I plan on getting a bunch of these so i can remotely control the valves.

Main question is can i control the PIDs, and thus the power to the elements (2x 6kw - 240v), or would i need to bypass them? I also wonder if i could plug into the 'auto' side of the pumps.

Effectively i need a new project and this is one i've been mulling over for some time.

Cheers

Hawk

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)