Find anyone with a cnc (even a hobby tabletop model) in your area, the labels are made from "tri-laminate" poly stock, you engrave the color on top showing the color in the middle of the laminate. Trophy shops normally have it too to make desk-door signs. If you can't find local, I have a antique (cantankerous) old bridgeport cnc I converted.

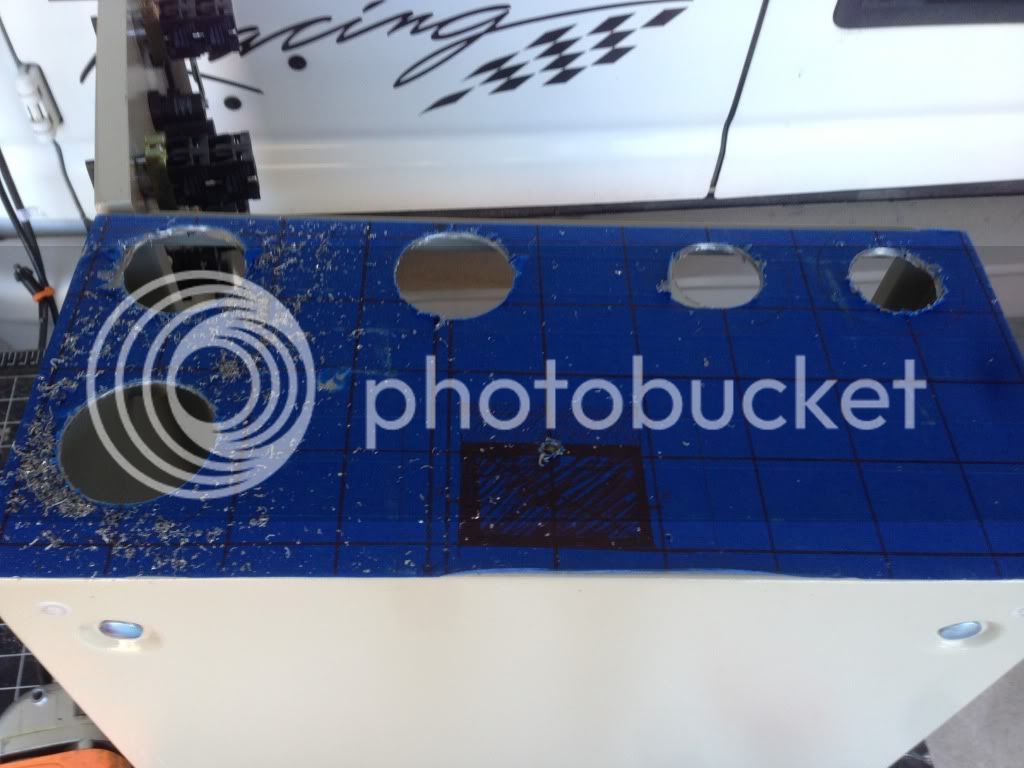

FOR the holes, (yes I know you are done) I have been using a plasma cutter with a template for about fifteen years now. Ten seconds per hole. HOLD the template, scribe with plasma torch, done. In Powerplants a jig saw vibration may knock offline relays controlling power and cities go black.

(thank you for putting me onto Chad for the filters, I will be in touch with him)

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)