OkieNotFromMuskogee

Active Member

That looks amazing - I especially love the unusual color

Thanks man! It's what was on sale

Prusa Orange?

Hatchbox On Sale Orange

That looks amazing - I especially love the unusual color

Prusa Orange?

That looks great!

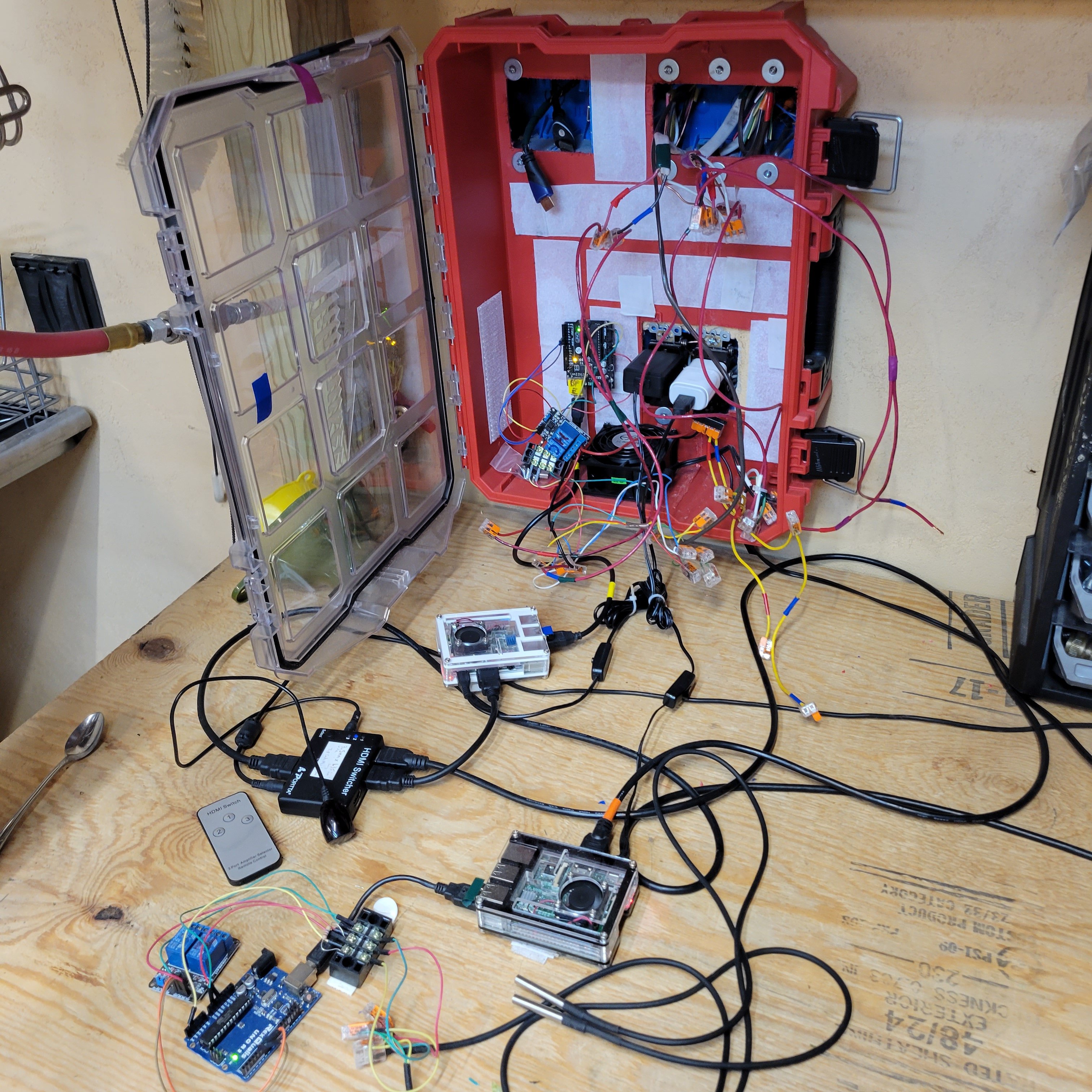

I need to figure out how to design in my supports. That seems to come out much better.

The pushbutton for the Pi is a gamechanger.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

It is - I was trying not to pile on because right now he's looking at those pieces of tape and eventually it will get to him enough to re-make it.Is it possible to embed text labels on the surface for those connectors & ports?

Is it possible to embed text labels on the surface for those connectors & ports?

Like "Heat" and "Cool" (or at least "H" and "C") above the duplex sockets?

The problem is: I'll bet he's got a > 1 day print there. If I were to guess, it's only about $5 in material, but tying up your printer for another day for an H and C is an emotional decision he needs to make.

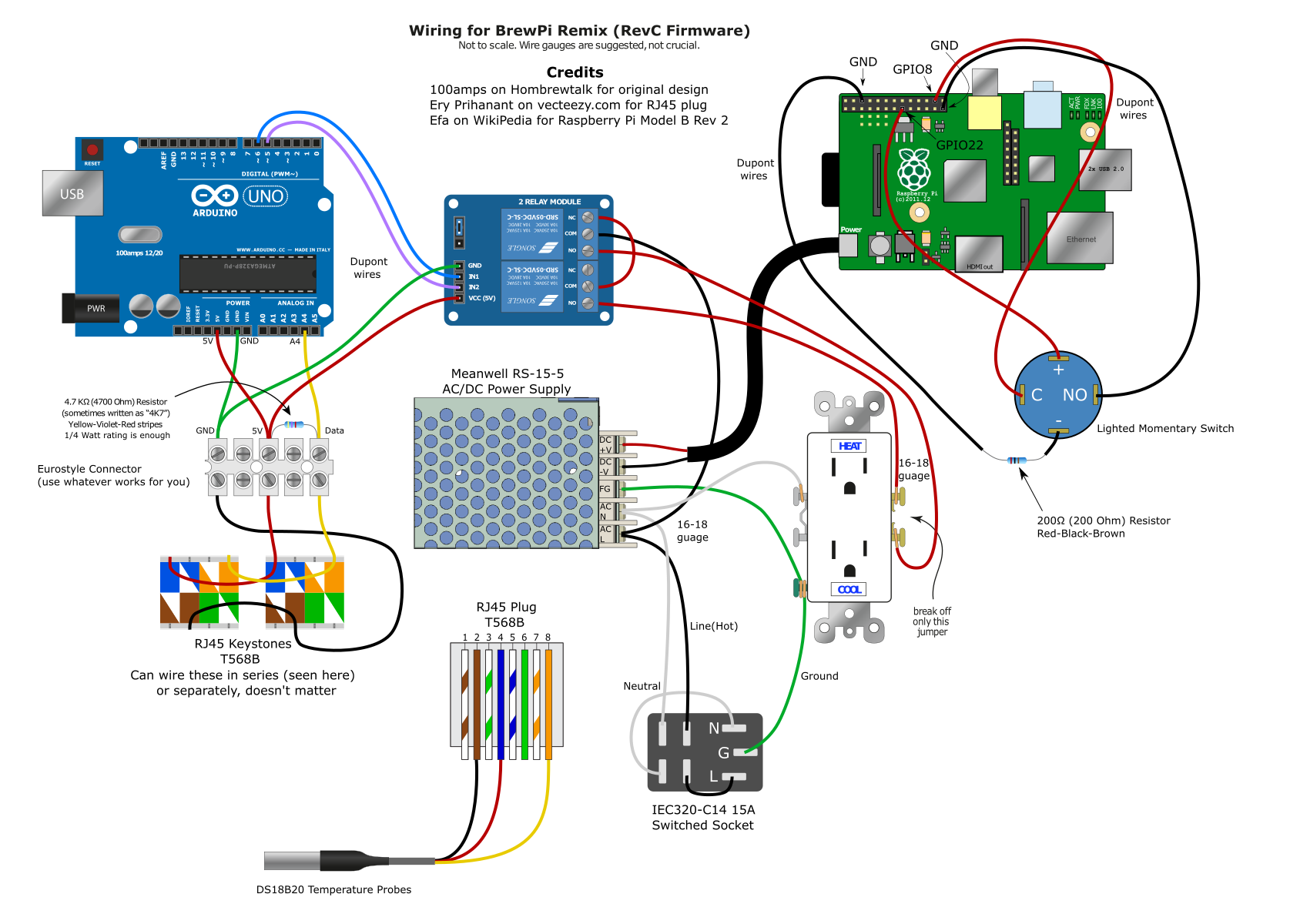

For the RJ45 jacks it says you can wire them in series like you did. That's actually parallel. But that's nitpicking.

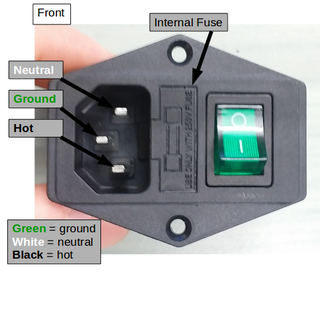

An enhancement I recommend is using a fused IEC power inlet. Say 8-10 amp fuse. But make sure it's one that has legitimate safety certifications. CSA/UL or whatever. The only way to ensure those certs are legit is to buy it from a responsible supplier. (Mouser, Digikey, etc.)

Such as these.An enhancement I recommend is using a fused IEC power inlet. Say 8-10 amp fuse. But make sure it's one that has legitimate safety certifications. CSA/UL or whatever. The only way to ensure those certs are legit is to buy it from a responsible supplier. (Mouser, Digikey, etc.)

Where is Dad's Pencil Sharpener in the box?No, I am referring to the switched AC bulkhead, as shown in the OP's illustration and outlined here:

View attachment 708978

Sadly, these are consistently mis-represented as "10 AMP" bulkheads even while the switch modules have "6A" molded into their shells...

Cheers!