yeah, there are a lot of options with this system... Too many to think about.

I will look into needle valves, do hardware stores carry them with 1/2" NPT?

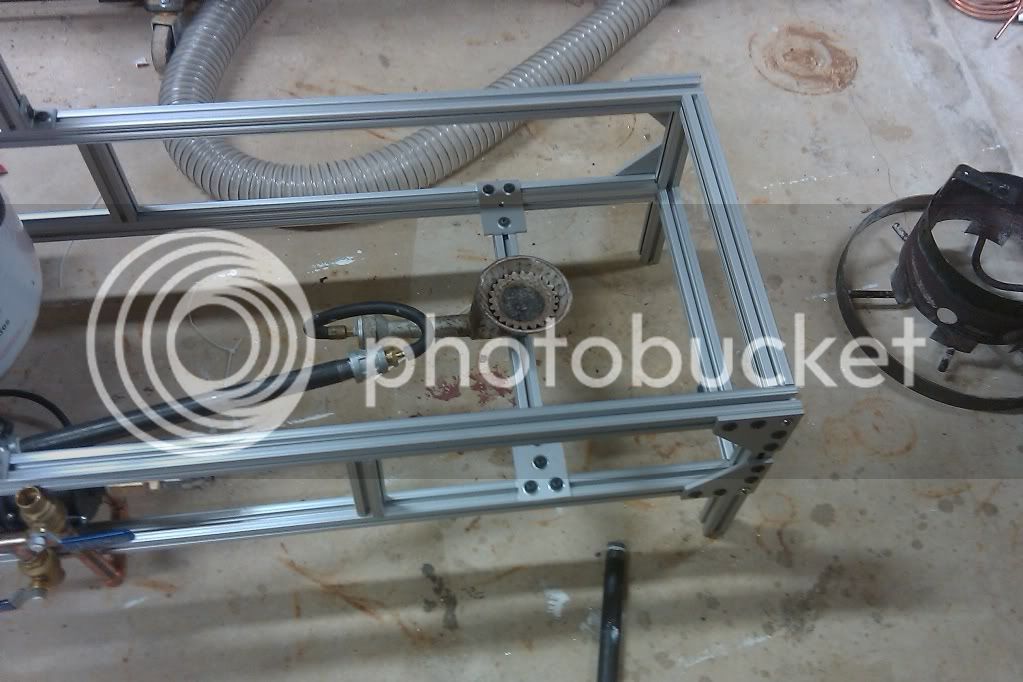

The tankless has a 6" stub of a vent, you can see 1/2" of it protruding on the top. I am probably going to just ad a 90° turn to keep it away from the cooler.

I am interested in going electric, but my garage is opposite of my electrical panel, and I have no 240Vac over there. In addition, the service panel is in the basement, the garage is on a slab obviously, and routing the electrical service there would require me to cut out the back of a closet and the basement ceiling... not fun.

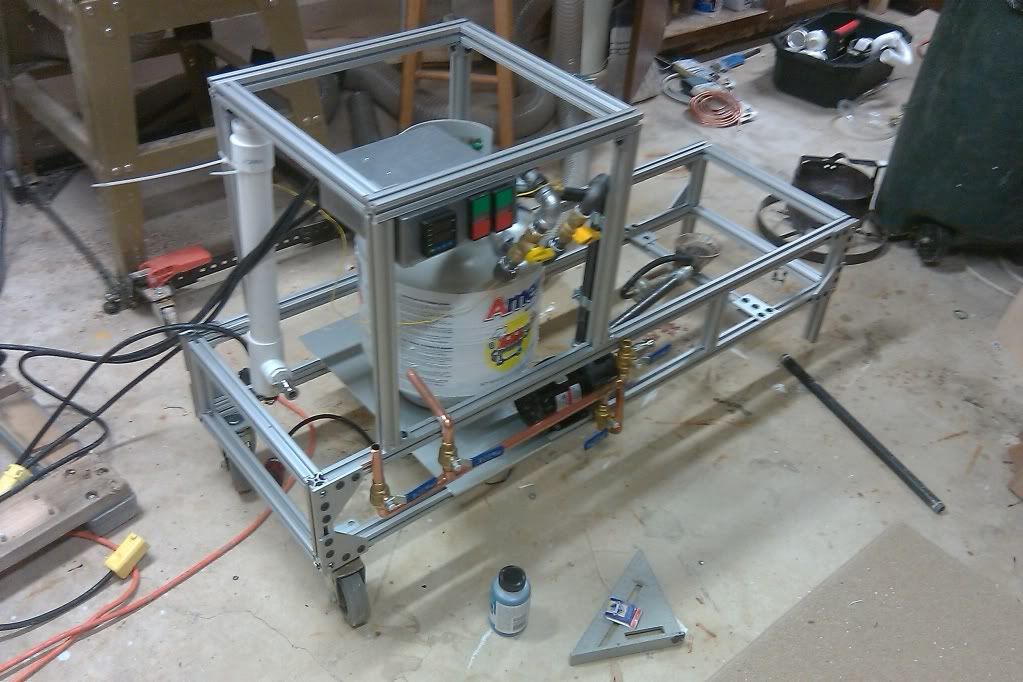

I kept the build that long since I might shift the cooler stand over a bit to give more room for the tankless heater. As it is now, the tankless heater will overhang by about 2 inches. Additionally, I wanted room for a 100qt kettle in case I ever needed it, and they are roughly 20-21" in diameter.

Thanks for the thoughts and feedback, keep them coming.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)