Naysayer

Member

Hello,

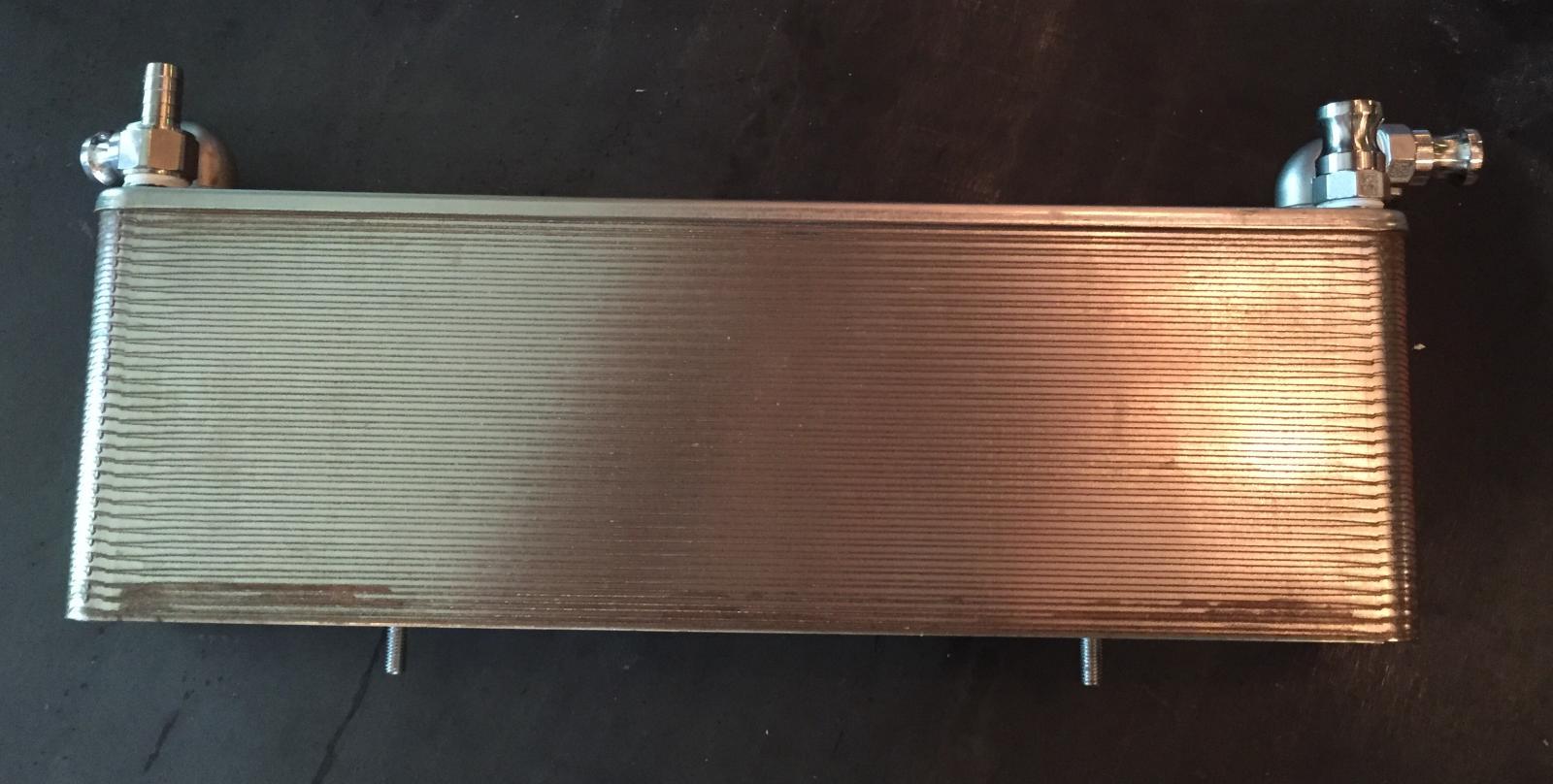

I have an 18", 60 plate counter-flow heat exchanger for sale. The model is B3-36A-60 with 1/2" Male NPT connections. The 1/2" NPT option enables more versatility with connections. You can find more details at Duda's website:

http://www.dudadiesel.com/choose_item.php?id=HX3660

If you're able to supply the cooling water flow rates (there are options for 5 GPM and 10 GPM on the chart), then this thing is capable of cooling down 10 gallons of wort in 2-4 mins (depends on your flow rates). You can access this information in the link below:

http://www.dudadiesel.com/files/beerwortchart.pdf

You will need two pumps to use this heat exchanger effectively: one for cooling water and one for wort. I've done a bunch of trials using only water before I used this in a brew session, and the flow rates are important. If you have a couple Chugger or March pumps with 5 GPM flow capability, then you should be set. I've been using two 809-PL-HS March pumps with good success. I've also experimented with ice water as the cooling fluid: this further improves the effectiveness. Also, using lower temperature cooling water can reduce the required flow rates, if needed.

Price:

List price from Duda Diesel: $275 +shipping

Asking price from me: $220 +shipping (I will only charge what the mail carrier charges)

Details of use and reasons for sale:

As mentioned, I've used this heat exchanger in a number of water trials and eventually in four 15-gallon all grain batches. It is in near perfect condition (maybe some small scratches on surface, if anything). The main reason I purchased this heat exchanger was to reduce the amount of water used during a brew session. The amount of cooling water was reduced immensely! However, having never used a plate heat exchanger (only immersion chillers), I underestimated how much water it takes to back flush/clean a plate heat exchanger. It's not a ridiculous amount of water by any means...similar to any other plate heat exchanger from what my friends tell me. It just doesn't meet my overall goal of an extremely low amount of water waste, so I have decided to try something else.

Feel free to ask me any questions. I will post some pictures of the item shortly.

Cheers!

I have an 18", 60 plate counter-flow heat exchanger for sale. The model is B3-36A-60 with 1/2" Male NPT connections. The 1/2" NPT option enables more versatility with connections. You can find more details at Duda's website:

http://www.dudadiesel.com/choose_item.php?id=HX3660

If you're able to supply the cooling water flow rates (there are options for 5 GPM and 10 GPM on the chart), then this thing is capable of cooling down 10 gallons of wort in 2-4 mins (depends on your flow rates). You can access this information in the link below:

http://www.dudadiesel.com/files/beerwortchart.pdf

You will need two pumps to use this heat exchanger effectively: one for cooling water and one for wort. I've done a bunch of trials using only water before I used this in a brew session, and the flow rates are important. If you have a couple Chugger or March pumps with 5 GPM flow capability, then you should be set. I've been using two 809-PL-HS March pumps with good success. I've also experimented with ice water as the cooling fluid: this further improves the effectiveness. Also, using lower temperature cooling water can reduce the required flow rates, if needed.

Price:

List price from Duda Diesel: $275 +shipping

Asking price from me: $220 +shipping (I will only charge what the mail carrier charges)

Details of use and reasons for sale:

As mentioned, I've used this heat exchanger in a number of water trials and eventually in four 15-gallon all grain batches. It is in near perfect condition (maybe some small scratches on surface, if anything). The main reason I purchased this heat exchanger was to reduce the amount of water used during a brew session. The amount of cooling water was reduced immensely! However, having never used a plate heat exchanger (only immersion chillers), I underestimated how much water it takes to back flush/clean a plate heat exchanger. It's not a ridiculous amount of water by any means...similar to any other plate heat exchanger from what my friends tell me. It just doesn't meet my overall goal of an extremely low amount of water waste, so I have decided to try something else.

Feel free to ask me any questions. I will post some pictures of the item shortly.

Cheers!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)