You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

$5.00 False Bottom Plan

- Thread starter zzARzz

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

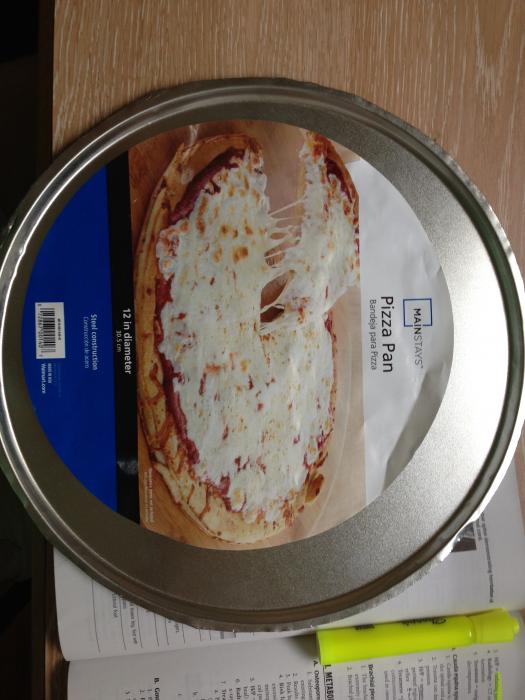

I loved this idea and I went with it. I found a pizza pan that says "steel" construction from Walmart. Any idea if this would be safe in a mash tun? I trimmed it down to size and it fits perfectly into the 10 gal rubbermaid. Here's a picture.

hyperboarder

Well-Known Member

I loved this idea and I went with it. I found a pizza pan that says "steel" construction from Walmart. Any idea if this would be safe in a mash tun? I trimmed it down to size and it fits perfectly into the 10 gal rubbermaid. Here's a picture.

It's a pizza pan so it's food grade, give it a shot.

zzARzz

Well-Known Member

- Joined

- Jul 7, 2012

- Messages

- 410

- Reaction score

- 52

I loved this idea and I went with it. I found a pizza pan that says "steel" construction from Walmart. Any idea if this would be safe in a mash tun? I trimmed it down to size and it fits perfectly into the 10 gal rubbermaid. Here's a picture.

That's basically the same thing I used in my 10 gallon Igloo mash tun and it has worked without a hitch. The hardest part is getting all of the barbs off of the bottom of it after you drill but with some patience and elbow grease it's good to go.

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

stamandster

undefined member

Instead of drilling I wonder if an awl could punch a hole that would work (providing it's thin enough stainless/aluminium). Use a piece of wood as a backer. Might go quicker...

Dude this is great. I added the SS 12" to my wishlist on amazon yesterday and it was $14 bucks. Looked at it today and it dropped to $8.56 with free second day shipping cuz of my Prime membership. I had been debating getting the FB from Jaybird for my 10G rubbermaid but i think this just saved me a ton of money.

Also for the barb issue, try a dremel sanding tool, thats what im gonna use. It worked great for the sharp edges on my keggle cuts.

One question though... how does it hold up with large grain bills? Any issue with bending?

Also for the barb issue, try a dremel sanding tool, thats what im gonna use. It worked great for the sharp edges on my keggle cuts.

One question though... how does it hold up with large grain bills? Any issue with bending?

zzARzz

Well-Known Member

- Joined

- Jul 7, 2012

- Messages

- 410

- Reaction score

- 52

Dude this is great. I added the SS 12" to my wishlist on amazon yesterday and it was $14 bucks. Looked at it today and it dropped to $8.56 with free second day shipping cuz of my Prime membership. I had been debating getting the FB from Jaybird for my 10G rubbermaid but i think this just saved me a ton of money.

Also for the barb issue, try a dremel sanding tool, thats what im gonna use. It worked great for the sharp edges on my keggle cuts.

One question though... how does it hold up with large grain bills? Any issue with bending?

I had 14 lbs of mash + water on my S/S 10 gallon one and it's still straight as an arrow. You could make some feet for it as others have done but I've had mine hollow for 10 + brews and it hasn't had an issue yet. For anything larger than a 10 gallon, though, 3 or 4 S/S feet w/ S/S screws may be a wise precaution.

zzARzz

Well-Known Member

- Joined

- Jul 7, 2012

- Messages

- 410

- Reaction score

- 52

Awesome, well I'm gonna go for it because it was only $0.98 at Walmart. zzARzz how did you get the barbs off the bottom? I might just get pliers for the big ones and leave the little ones.

I used a grill cleaning tool with a scraper on one end and a metal brush on the other. The scraper got the big pieces off and the brush got the smaller stuff. Only took a few minutes to get it pretty clean.

zzARzz

Well-Known Member

- Joined

- Jul 7, 2012

- Messages

- 410

- Reaction score

- 52

Instead of drilling I wonder if an awl could punch a hole that would work (providing it's thin enough stainless/aluminium). Use a piece of wood as a backer. Might go quicker...

I thought about that initially, but the punch I have is angled so I was worried about the holes either being too big or of different sizes that may have caused channeling while sparging. I figured the drill, while it takes a lot longer, keeps everything uniform.

Just finished up the holes earlier. Used my DeWalt drill and alternated two 1/8" bits with drill oil and after about an hour I got them all done. Gonna take the dremel to it tomorrow or Sunday when I get time and then head to Lowes to get the elbow and tubing. Can't wait to see how it turns out.

zzARzz

Well-Known Member

- Joined

- Jul 7, 2012

- Messages

- 410

- Reaction score

- 52

Just finished up the holes earlier. Used my DeWalt drill and alternated two 1/8" bits with drill oil and after about an hour I got them all done. Gonna take the dremel to it tomorrow or Sunday when I get time and then head to Lowes to get the elbow and tubing. Can't wait to see how it turns out.

Certainly post pictures of it if you can when it's done. With as easy as this is I don't think I could ever justify spending as much as is wanted for a pre-made false bottom. I got through about 3 episodes of South Park in the amount of time it took me to make mine

So glad I found this thread! I am for sure doing this. Going to pick up the following off of amazon:

http://www.amazon.com/Stainless-Steel-Pizza-Pan-Diameter/dp/B002UG7QVI/ref=sr_1_1?ie=UTF8&qid=1374276111&sr=8-1&keywords=stainless+steel+pizza+pan

Based on the reviews, I am loving the possibility of this being a great false bottom:

"...the lip is a good 1 1/2 inches and the graduation makes this a one use pan..."

...not for me it doesn't. Sounds awesome!

12 bucks for the SS Pizza Pan + another 5 bucks for other hardware to hook it all up = totally kick ass false bottom for under 20 bucks!

http://www.amazon.com/Stainless-Steel-Pizza-Pan-Diameter/dp/B002UG7QVI/ref=sr_1_1?ie=UTF8&qid=1374276111&sr=8-1&keywords=stainless+steel+pizza+pan

Based on the reviews, I am loving the possibility of this being a great false bottom:

"...the lip is a good 1 1/2 inches and the graduation makes this a one use pan..."

...not for me it doesn't. Sounds awesome!

12 bucks for the SS Pizza Pan + another 5 bucks for other hardware to hook it all up = totally kick ass false bottom for under 20 bucks!

Last edited by a moderator:

I loved this idea and I went with it. I found a pizza pan that says "steel" construction from Walmart. Any idea if this would be safe in a mash tun? I trimmed it down to size and it fits perfectly into the 10 gal rubbermaid. Here's a picture.

It's a pizza pan so it's food grade, give it a shot.

"Food grade" is not a good measure for this (ab)use. In the short run it may hold up, but since your mash is sour (pH of around 5.2) it will degrade (dissolve) the tin coating on the pan and then attack the steel. Aluminum won't fare any better.

Using a SS pan is the only way to keep it from becoming part of your beer.

The burrs can be removed by spinning a slightly larger drill bit in the burr-side of the holes. A very, very slow running drill can help if you don't want to do it by hand, just watch out it doesn't "catch" and make a bigger hole. Dremel tools are useful too.

zzARzz

Well-Known Member

- Joined

- Jul 7, 2012

- Messages

- 410

- Reaction score

- 52

So glad I found this thread! I am for sure doing this. Going to pick up the following off of amazon:

http://www.amazon.com/Stainless-Steel-Pizza-Pan-Diameter/dp/B002UG7QVI/ref=sr_1_1?ie=UTF8&qid=1374276111&sr=8-1&keywords=stainless+steel+pizza+pan

Based on the reviews, I am loving the possibility of this being a great false bottom:

"...the lip is a good 1 1/2 inches and the graduation makes this a one use pan..."

...not for me it doesn't. Sounds awesome!

12 bucks for the SS Pizza Pan + another 5 bucks for other hardware to hook it all up = totally kick ass false bottom for under 20 bucks!

That's the same pan I used for my 10 gallon cooler and it has worked really well. I did a blonde ale last week and with the addition of some rice hulls (my first time using them) the false bottom performed flawlessly with an 85% efficiency.

One note, though, I'll get about a pinch of grist that comes out during the sparge, but I clip a mesh strainer to the side of my brew pot and set the flow tube from the MLT in the strainer to catch anything that gets through. Other than that the only thing I do is change the dip tube about every 5 brews since the braided vinyl tubing tends to get hard and brittle, but eventually I'm going to make a SS dip tube with compression fittings which I'll post when I get around to it.

I'm glad you like the design and happy brewing!

Last edited by a moderator:

zzARzz

Well-Known Member

- Joined

- Jul 7, 2012

- Messages

- 410

- Reaction score

- 52

"Food grade" is not a good measure for this (ab)use. In the short run it may hold up, but since your mash is sour (pH of around 5.2) it will degrade (dissolve) the tin coating on the pan and then attack the steel. Aluminum won't fare any better.

Using a SS pan is the only way to keep it from becoming part of your beer.

The burrs can be removed by spinning a slightly larger drill bit in the burr-side of the holes. A very, very slow running drill can help if you don't want to do it by hand, just watch out it doesn't "catch" and make a bigger hole. Dremel tools are useful too.

When I made the first iteration of this false bottom I used an anodized aluminum pan for my 5 gal MLT since I didn't know if this was going to work or not and it was really cheap, but I was pleasantly surprised to find it held up without any signs of corrosion or weird flavors in the beer.

Having had some experience with it now, however, I would agree with your recommendation of going with a SS pan rather than aluminum or coated steel, especially for MLTs of 10 gallons +.

http://www.amazon.com/Stainless-Ste...dp_top_cm_cr_acr_txt?ie=UTF8&showViewpoints=1

Gave ya some props on Amazon and posted the link. Just got an email, it helped someone decide to purchase it already lol

Gave ya some props on Amazon and posted the link. Just got an email, it helped someone decide to purchase it already lol

ChocolateMaltyBalls

Well-Known Member

I just ordered mine the other day, right after a big price drop. I'm looking forward to getting rid of my bazooka screen, and maybe start fly sparging. Thanks dude!

Chrissthomas

Member

I am looking to move into all grain so I have been researching building a false bottom and this thread is great. I do have a question. John Palmer says this in chapter 17 of how to brew, "Another extraction efficiency problem that needs to be considered when designing your tun is preferential flow down the walls. The smooth space between the grainbed and the wall of the tun can be the path of least resistance to the drain. To minimize this short circuiting, false bottoms should fit tightly". I am curious how some of these FBs are fairing in efficiency, in light of this preferential flow. Some of the pictures shown clearly show a false bottom smaller than the mash tun itself. I am very interested especially in the plastic microwave screen because it seemed the easiest to find/make and you don't have to worry about trying to find a stainless steel one. Did anyone make that plastic one and have problems with preferential flow or even the plastic colapsing under the weight of the grain?

vinylrooster

Well-Known Member

Hey Everyone,

I wanted to do my first all-grain brew and did a lot (A LOT) of research into to the best methods, costs involved, etc. I decided that the false bottom would give me the most flexibility, but at anywhere from $30-$100 for professionally made ones, my inner Scrooge said, "Bah, humbug!" So I did some more looking and came up with my own using only $5 worth of parts. It's for a 5 gallon Igloo beverage cooler, but the design is simple and could be modified for almost any size round mash tun. I'll admit I'm as green as one gets to brewing and would greatly appreciate any comments and suggestions about my design. It's still untested, but I'll be brewing a Scottish Heavy Ale next week and will post an update as to how it performed.

Parts List

(1) 9" 18-gauge Aluminum Pizza Pan; 0.4" depth - {I got mine from a restaurant supply store} - $2.88

(1) PEX Elbow Adapter; brass - {From Home Depot in the plumbing section} - $1.71

(2) #31 O-Rings - {Home Depot in the faucet repair section} - $0.23/ea

1/8" drill bit

1/2" or 3/8" drill bit - {Depending on your inlet size; I made my assembly out of 1/2" parts, so I used a 1/2" bit}

Variable speed drill

Ruler or T-Square

Pencil

Scotch Tape

Old cutting board or sheet of wood

Safety Glasses - {Better to look like a dork for an hour that a pirate the rest of your life}

How To

Begin by taping the pizza pan domed side up to the cutting board. This will make it easier for the rest of the steps. Use the ruler or T-Square to draw a straight line down the center of the pan. Rotate it 90 degrees and make another line so the cross marks the center of the pan. Mark the lines every 1/2" from the center out to the edges on each axis. Finally draw parallel lines at each mark to form a grid:

Put on your goggles and start drilling 1/8" holes at each point on the grid. There'll be about 250 of them so it'll take a while.

When that's done, use the 1/2" or 3/8" bit to drill the port in the center of the pan for the PEX elbow. Use a wire brush, sandpaper or the like to clean all the barbs off the underside of the pan from drilling. Wash the pencil grid of the pan and use a garden hose or high pressure water to clean off any metal flakes that may have collected in the rolled rim of the pan.

Take one of the O-Rings and push it onto the inlet side of the PEX elbow about halfway down the barb. Insert the elbow into the port in the center of the pan so it looks like this:

Holding it in place, take the other O-Ring and push it over the inlet barb on the underside of the pan. The PEX elbow should be held firmly in place, decently sealed and easily rotated:

Here's mine installed in my mash tun. I used 3" of 1/2" braided tubing to hold mine in place and it is held snugly. You could also use copper tubing with compression fittings, but I find this way much easier to deal with as far as installation and cleaning are concerned.

I put 1 gallon of water into the tun to test dead space and it was only 1/4 gallon short, so not too bad. Hopefully some of you can mess around with the design and I'll post my findings when I brew next week.

NOTE

11/16/2012 -- A few people have mentioned that due to the lightness of aluminum there have some issues with the false bottoms floating while mashing, causing stuck sparges by grist getting caught in the dip-tubes and lines. One way to remedy this is to use rigid, braided food-safe tubing from the PEX elbow to the barb on the valve. This is what I use and I haven't had an issue with floating or stuck sparges.

Another would be to use compression fittings and copper/SS tubing which would keep the false bottom in place as well. This is what I'll likely use when I upgrade to a 10 gallon mash tun in the future.

Finally, adding weights to the false bottom such as SS washers above and below the PEX elbow or weights mounted along the upper edge of the rim would likely cure this issue as well.

Update

I brewed with this false bottom for the first time today and I’m honestly impressed at how well it worked! Hit 85% efficiency and had only a pinch of grain material come out while fly sparging. The tun had a fast, steady flow and didn’t even hint at a slow or stuck sparge. Had exactly 5.7 gallons of wort which was what BeerSmith predicted.

Even though this is my first all-grain brew, this false bottom worked much better than my friend’s who uses the braided S/S line method. She often has to fiddle with it and complains of stuck sparges all the time. Cheap B-Day present, perhaps?

I got the hole size and spacing parameters from a fantastic article I read by John J. Palmer and Paul Prozinski here: http://morebeer.com/brewingtechniques/library/backissues/issue3.4/palmer.html. It has some great info on improving mash efficiency and it taught me quite a bit.

UPDATE

12/3/2012 - I upgraded to a 10 gallon Igloo cooler for my mash tun to do higher gravity brews and made a new false bottom. This one is made from a 12" stainless steel pizza pan I purchased from Amazon for $13. I cannibalized the parts from my 5 gallon mash tun and they work flawlessly. Here you can see the the false bottom made with the same 1/8" drilled holes at 1/2" offsets. I set the PEX pickup end as low as possible under the false bottom as this pan is a bit deeper than the 9" in the previous build. Hopefully this will minimize the wort lost to dead space. I'm planning an Imperial IPA next and will report the new mash tun's performance once it is complete.

UPDATE

12/29/2012: Brewed an Imperial IPA with the new 10 gal mash tun and 12" pizza pan false bottom. Worked even better than the original 9" version. The addition of S/S hose clamps on the dip tube made grain material in the 8qt re-circulation almost non-existent so I highly recommend using them with this design. Hit 82% efficiency and there was no hint of a stuck sparge (very smooth, slow, steady flow). I'm very happy that a second iteration of this design has proven as effective as the original.

I know what I'm doing this weekend. Great diy build, thanks for posting

I am looking to move into all grain so I have been researching building a false bottom and this thread is great. I do have a question. John Palmer says this in chapter 17 of how to brew, "Another extraction efficiency problem that needs to be considered when designing your tun is preferential flow down the walls. The smooth space between the grainbed and the wall of the tun can be the path of least resistance to the drain. To minimize this short circuiting, false bottoms should fit tightly". I am curious how some of these FBs are fairing in efficiency, in light of this preferential flow. Some of the pictures shown clearly show a false bottom smaller than the mash tun itself. I am very interested especially in the plastic microwave screen because it seemed the easiest to find/make and you don't have to worry about trying to find a stainless steel one. Did anyone make that plastic one and have problems with preferential flow or even the plastic colapsing under the weight of the grain?

The false bottom on this will fit tightly, the weight of the plate itself will keep it down if its Stainless Steel. Some people posted previously about the aluminum one floating, and ive read other threads with people using plastic and it floating too. Ur better off going with SS as that won't bend in the middle under the pressure of heavy grain bills like the plastic one could. Plus with high temps, plastic becomes more pliable so i think thats even more recipe for something to go wrong.

zzARzz

Well-Known Member

- Joined

- Jul 7, 2012

- Messages

- 410

- Reaction score

- 52

I am looking to move into all grain so I have been researching building a false bottom and this thread is great. I do have a question. John Palmer says this in chapter 17 of how to brew, "Another extraction efficiency problem that needs to be considered when designing your tun is preferential flow down the walls. The smooth space between the grainbed and the wall of the tun can be the path of least resistance to the drain. To minimize this short circuiting, false bottoms should fit tightly". I am curious how some of these FBs are fairing in efficiency, in light of this preferential flow. Some of the pictures shown clearly show a false bottom smaller than the mash tun itself. I am very interested especially in the plastic microwave screen because it seemed the easiest to find/make and you don't have to worry about trying to find a stainless steel one. Did anyone make that plastic one and have problems with preferential flow or even the plastic colapsing under the weight of the grain?

I usually hit 80%+ efficiency with my SS one and haven't had any issues as far as channeling is concerned. In my Igloo cooler, at least, the pan fits snugly under the barb adapter inside the mash tun and with the threaded tubing and weight of the mash it holds down well. When draining the wort I always run it through a mesh strainer to catch any bits that may have gotten through and I never have more than a pinch or two of grist.

One modification that I have played with and would alleviate any concern regarding the false bottom floating up, but that I haven't gotten around to doing on mine, is to use a SS dip tube with compression fittings angled slightly to keep the whole thing rigid and tight.

I don't have any experience with the plastic screens that some have used, but as long as you put some support feet on it between the false bottom and the bottom of the cooler I imagine it wouldn't have any issues flexing under the wort temp/grist weight, but I have no idea if floating would still be problematic.

BethelLight

Active Member

... Did anyone make that plastic one and have problems with preferential flow or even the plastic collapsing under the weight of the grain?

I built the plastic false bottom on my first all grain system in an effort to save money. It worked good. However I did have a couple of problems that needed work arounds.

1) To keep it from collapsing and stopping flow I used the largest 90 deg elbow I could find and then put notches in the portion that protruded through the bottom (see picture).

2) It did eventually loose it's original shape due to the heat and weight of the grain. To compensate for this and potential lifting I would put a 1 gal strainer bag that I bought at Lowes over the entire false bottom. This would prevent a stuck mash by keeping grain from potentially getting under the false bottom.

I believe it is safe to say that "every" false bottom that just sits on the bottom of the mash tun has the potential to lift and allow grain to get under it. I have friends who have had this problem with stainless steel ones they purchased online or from their homebrew shop.

I got great efficiency with this false bottom but to be honest it was just a cheap way for me to start doing all-grain without spending a lot of money. I have since moved on. I hope you enjoy your journey as much as I have! :-D

Thom

FalconsBrew

Well-Known Member

- Joined

- Jan 7, 2013

- Messages

- 84

- Reaction score

- 9

The pan linked earlier is about $20 now. What do you guys think about this one?

http://www.amazon.com/dp/B0000CFM7Q/?tag=skimlinks_replacement-20

http://www.amazon.com/dp/B0000CFM7Q/?tag=skimlinks_replacement-20

Last edited by a moderator:

Think it would work just fine.

Similar threads

- Replies

- 0

- Views

- 216

- Replies

- 1

- Views

- 306

- Replies

- 0

- Views

- 272

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)