JB_Brewing2

Well-Known Member

Limulus has offered a nice perspective and I'll throw my two cents in from another area of the country with a variation on set-up.

Right on OneManBrewery....I am just a week behind you eagerly awaiting my Medium BIAC.

I am hoping that the experienced on this forum can answer a few basic questions I have.

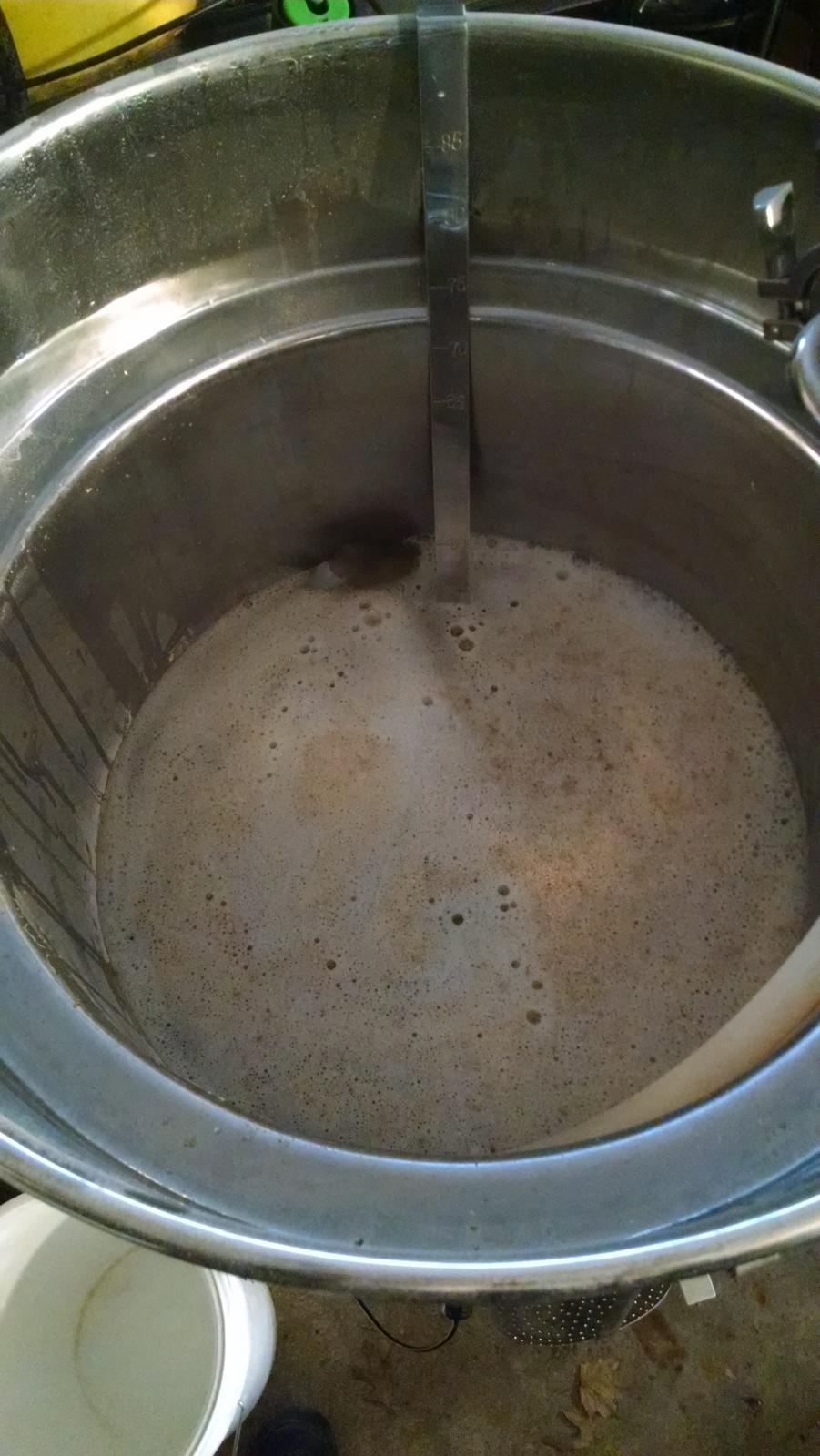

1. To sparge or not to sparge....Does anybody heat water in the jacket to sparge, or is the consensus to just add more grain and let the MT drain? I raise the colander and fly sparge for a short time until the wort is clear. My jacket is only used for efficiently cooling with the 53 degree municipal water.

2. Does anybody use the chiller to cold crash to 40F ( the coldest setting) before transferring to the keg? And if you use glycol in the jacket do you use PBW to clean if using the jacket for sparge water on the next brew? The jacket is my chiller and I crash in the keg after fermentation is complete.

3. Are the settings in Beersmith for the BIAC good, or are there tweaks that need to be made? Suggestions appreciated. Tweak it definitely; not for grain, hops, or yeast quantities, but certainly for boil size.

4. I've been doing 5 gallon batches with my gravity system. Is the Beersmith program accurate when scaling to a 10 gallon batch? I have several recipes from my five gallon gravity days and have had no issues converting ingredients from 5 to 10 gallons.

5. Any advice for the initial setup besides what is on the Brewha website? I have the original valves and have had no issues with blockage. This may be a result of my use of whole leaf hops secured in the Brewha hop containers rather than pellets although I don't know for sure.

Thanks....Cheers

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)