Hey.

Time for my second brew! Last time around things didn't go too smooth but I did learn alot about brewing and my setup. Got few questions before diving back in, and I realize most of these are probably answered million times over so sorry about that.

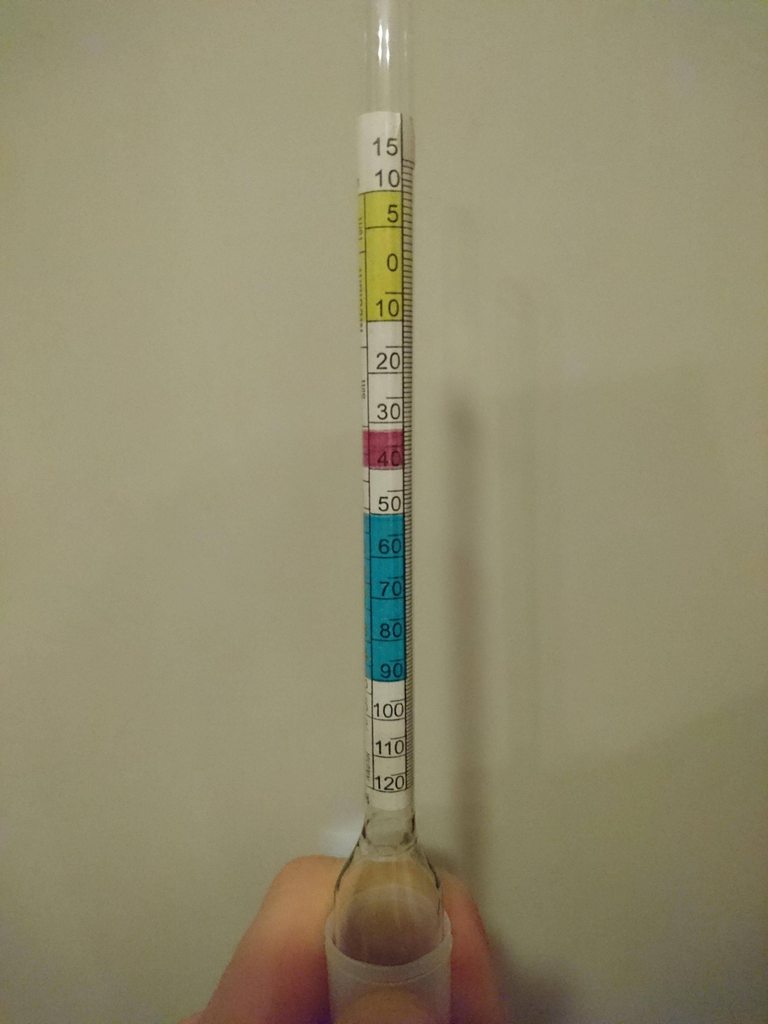

Last brew had really metallic after taste and was really strong. Since my og measurements went sideways I have no idea how much, but it really got you drunk. Strong alcohol taste too. Going to get some better measurements this time!

During fermentation the room temperature got really high couple times, so that probably had a lot to do with the off tastes. Now I got better place for my fermenter with temp around 18-20C (62-68F). Going to put the fermenter into water bucket with some wet cloth on top too. That should be enough to keep the temp from going up?

Last time I planned to use two kettles for boiling and ended up using 3. Boil off was insane and it was crazy mess to boil. This time I will make smaller 2,5 gallon batch and stick with just 1 kettle. Also noticed that my bottling bucket had alot of scratches on the inside and from what I understand that can lead to infections, off tastes and even ruining the beer due not sanitizing? And as 8 gallon bucket would have ton of headspace for 2,5 gallon batch, I figured I will get new 3 gallon fermenter with tap on the bottom. Could skip getting new bottling bucket and less headspace.

Since I will be making small batch and need new measuring jar anyways, I was thinking of getting Fermtech Wine Thief. It's supposedly allows for easy return of the sample back to fermenter. Tempted to save the samples since going for small batch but sounds like high possibility for infection?

I didn't dryhop my first brew and was thinking of doing that now. I read that 7-14g per gallon would be ok? Felt a bit high but I do love dem hoppy beers.

Since I have no idea about my efficiency, I set it to 80%. Last time I went with 60, but it was alot more since my OG was high. Doing fly sparge and mashing in diy-cooling box mash tun.

Would it be good idea to lower the efficiency on the recipe and aim for lower OG? If I get tad higher it wouldnt be too strong?

Here's the recipe I made. I ain't no expert so if something doesn't seem right, please let me know!

Brew2 (American Pale Ale)

Original Gravity (OG): 1.055 (°P): 13.6

Final Gravity (FG): 1.014 (°P): 3.6

Alcohol (ABV): 5.40 %

Colour (SRM): 9.2 (EBC): 18.1

Bitterness (IBU): 56.9 (Average - No Chill Adjusted)

90% American 2-Row

10% Crystal 60

1.1 g/L Amarillo (8.6% Alpha) @ 60 Minutes (Boil)

1.1 g/L Simcoe (12.2% Alpha) @ 15 Minutes (Boil)

0.5 g/L Citra (11.1% Alpha) @ 5 Minutes (Boil)

1.1 g/L Amarillo (8.6% Alpha) @ 7 Days (Dry Hop)

0.5 g/L Citra (11.1% Alpha) @ 7 Days (Dry Hop)

1.1 g/L Simcoe (12.2% Alpha) @ 7 Days (Dry Hop)

Single step Infusion at 66°C for 60 Minutes. Boil for 60 Minutes

Fermented at 20°C with Safale US-05

Cheers!

Time for my second brew! Last time around things didn't go too smooth but I did learn alot about brewing and my setup. Got few questions before diving back in, and I realize most of these are probably answered million times over so sorry about that.

Last brew had really metallic after taste and was really strong. Since my og measurements went sideways I have no idea how much, but it really got you drunk. Strong alcohol taste too. Going to get some better measurements this time!

During fermentation the room temperature got really high couple times, so that probably had a lot to do with the off tastes. Now I got better place for my fermenter with temp around 18-20C (62-68F). Going to put the fermenter into water bucket with some wet cloth on top too. That should be enough to keep the temp from going up?

Last time I planned to use two kettles for boiling and ended up using 3. Boil off was insane and it was crazy mess to boil. This time I will make smaller 2,5 gallon batch and stick with just 1 kettle. Also noticed that my bottling bucket had alot of scratches on the inside and from what I understand that can lead to infections, off tastes and even ruining the beer due not sanitizing? And as 8 gallon bucket would have ton of headspace for 2,5 gallon batch, I figured I will get new 3 gallon fermenter with tap on the bottom. Could skip getting new bottling bucket and less headspace.

Since I will be making small batch and need new measuring jar anyways, I was thinking of getting Fermtech Wine Thief. It's supposedly allows for easy return of the sample back to fermenter. Tempted to save the samples since going for small batch but sounds like high possibility for infection?

I didn't dryhop my first brew and was thinking of doing that now. I read that 7-14g per gallon would be ok? Felt a bit high but I do love dem hoppy beers.

Since I have no idea about my efficiency, I set it to 80%. Last time I went with 60, but it was alot more since my OG was high. Doing fly sparge and mashing in diy-cooling box mash tun.

Would it be good idea to lower the efficiency on the recipe and aim for lower OG? If I get tad higher it wouldnt be too strong?

Here's the recipe I made. I ain't no expert so if something doesn't seem right, please let me know!

Brew2 (American Pale Ale)

Original Gravity (OG): 1.055 (°P): 13.6

Final Gravity (FG): 1.014 (°P): 3.6

Alcohol (ABV): 5.40 %

Colour (SRM): 9.2 (EBC): 18.1

Bitterness (IBU): 56.9 (Average - No Chill Adjusted)

90% American 2-Row

10% Crystal 60

1.1 g/L Amarillo (8.6% Alpha) @ 60 Minutes (Boil)

1.1 g/L Simcoe (12.2% Alpha) @ 15 Minutes (Boil)

0.5 g/L Citra (11.1% Alpha) @ 5 Minutes (Boil)

1.1 g/L Amarillo (8.6% Alpha) @ 7 Days (Dry Hop)

0.5 g/L Citra (11.1% Alpha) @ 7 Days (Dry Hop)

1.1 g/L Simcoe (12.2% Alpha) @ 7 Days (Dry Hop)

Single step Infusion at 66°C for 60 Minutes. Boil for 60 Minutes

Fermented at 20°C with Safale US-05

Cheers!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)