Hey guys,

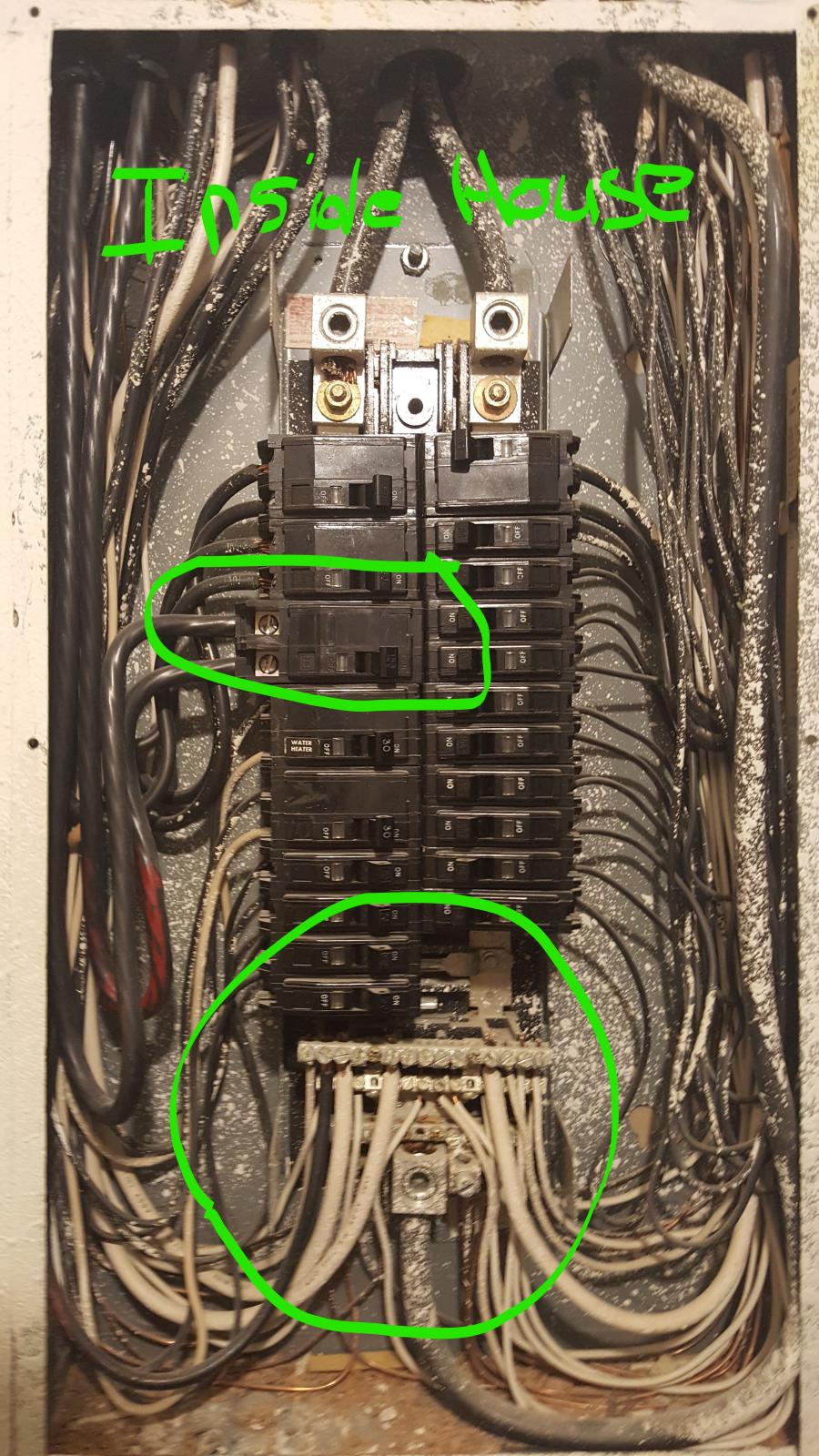

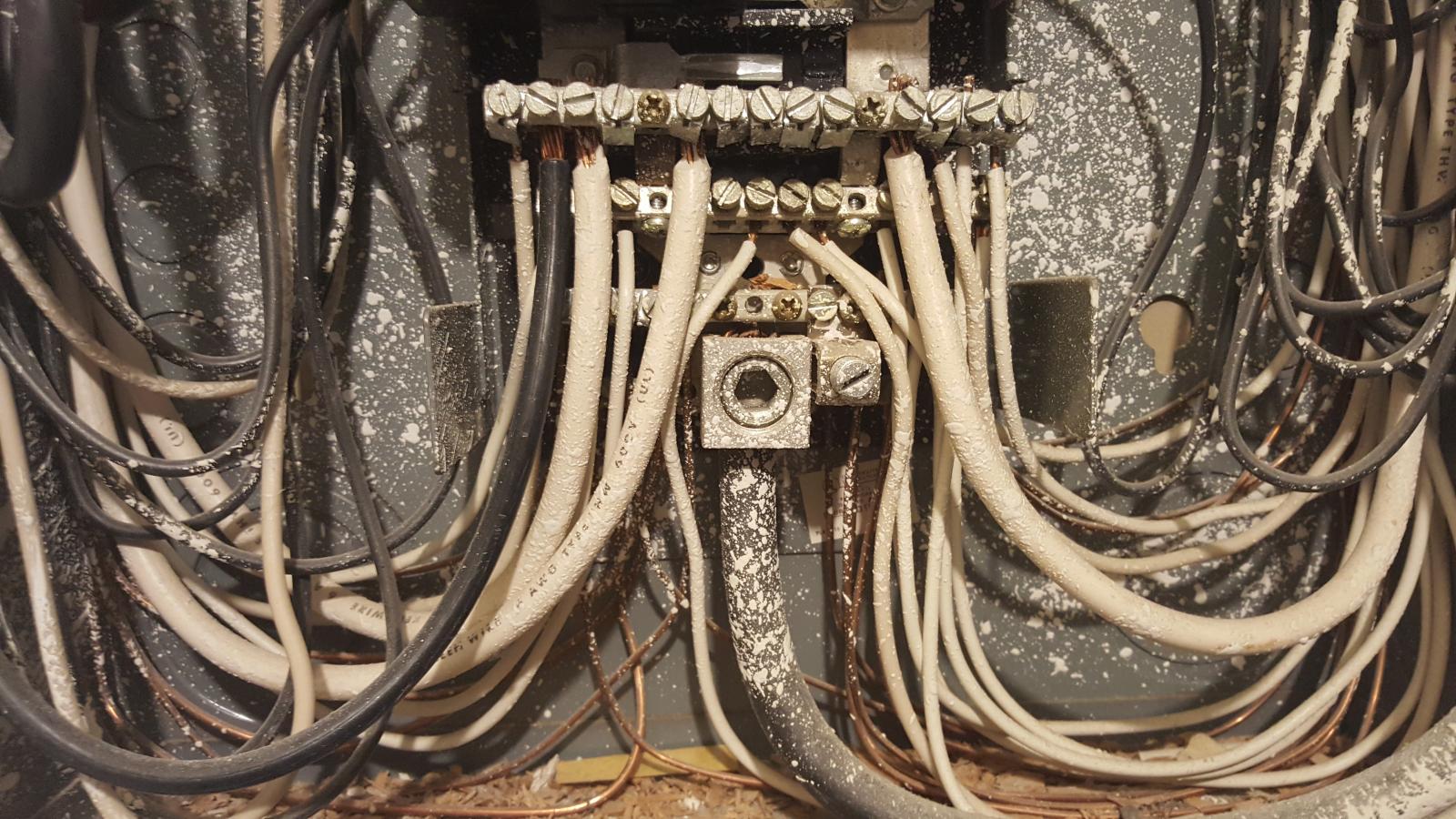

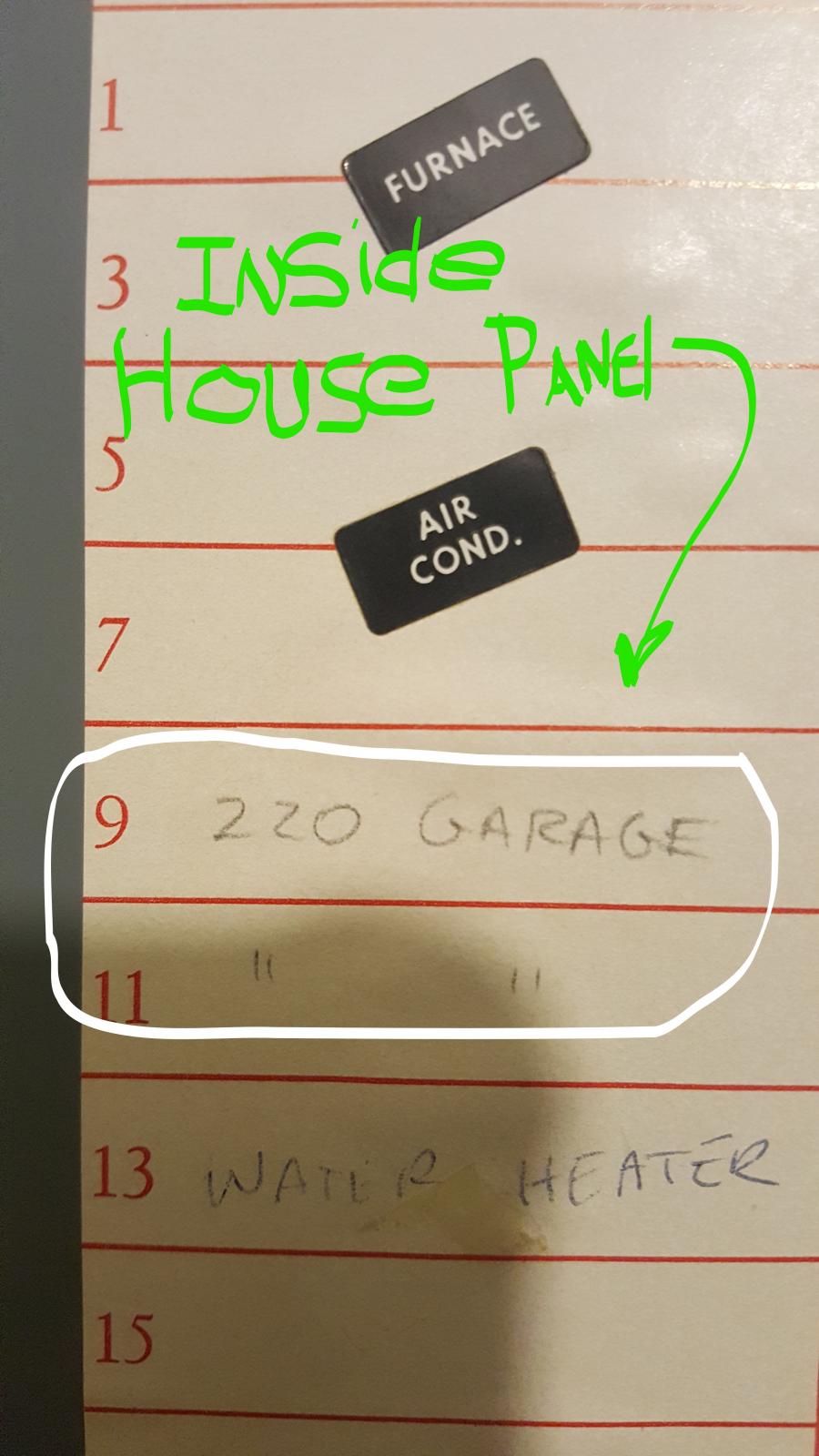

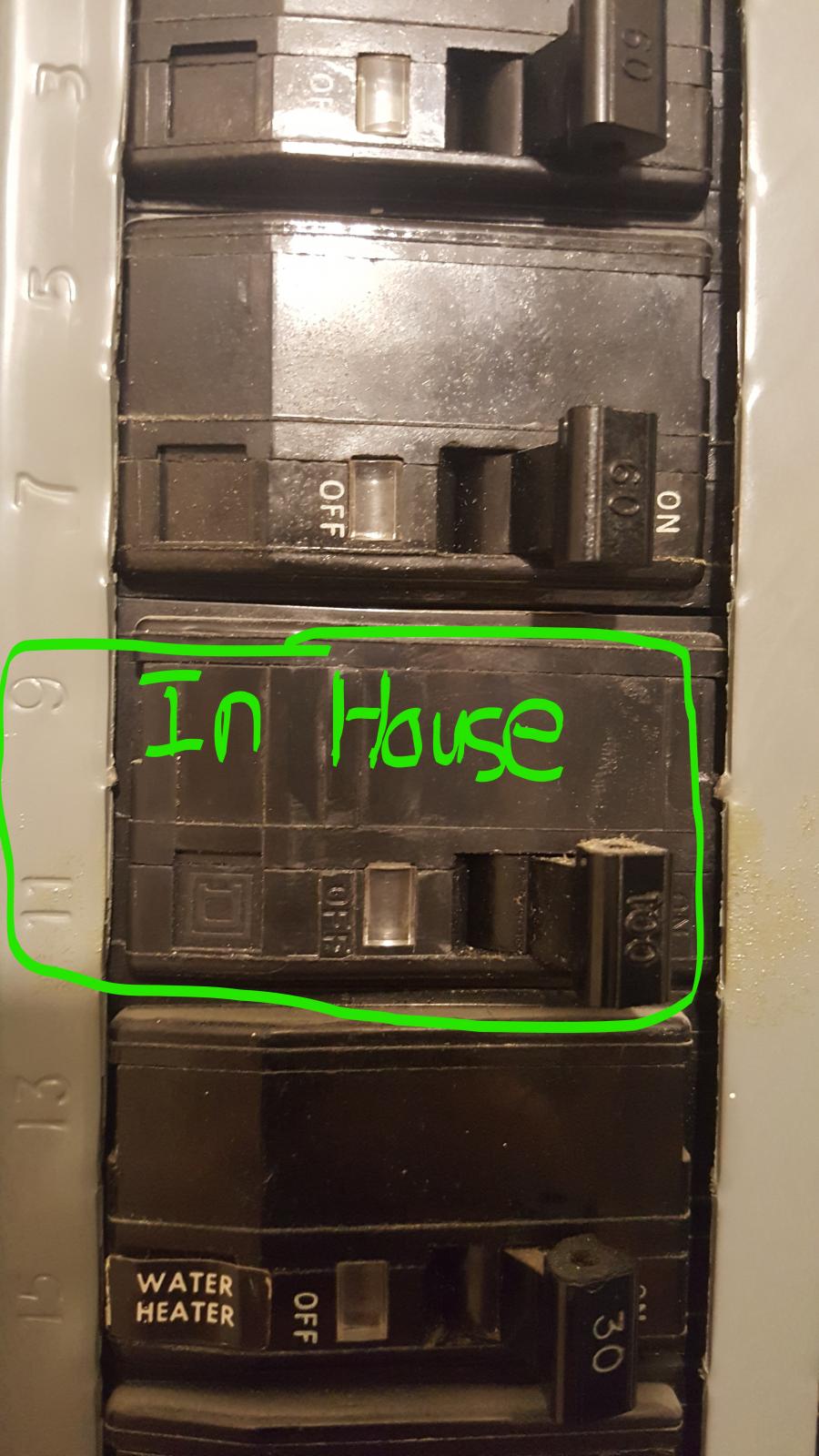

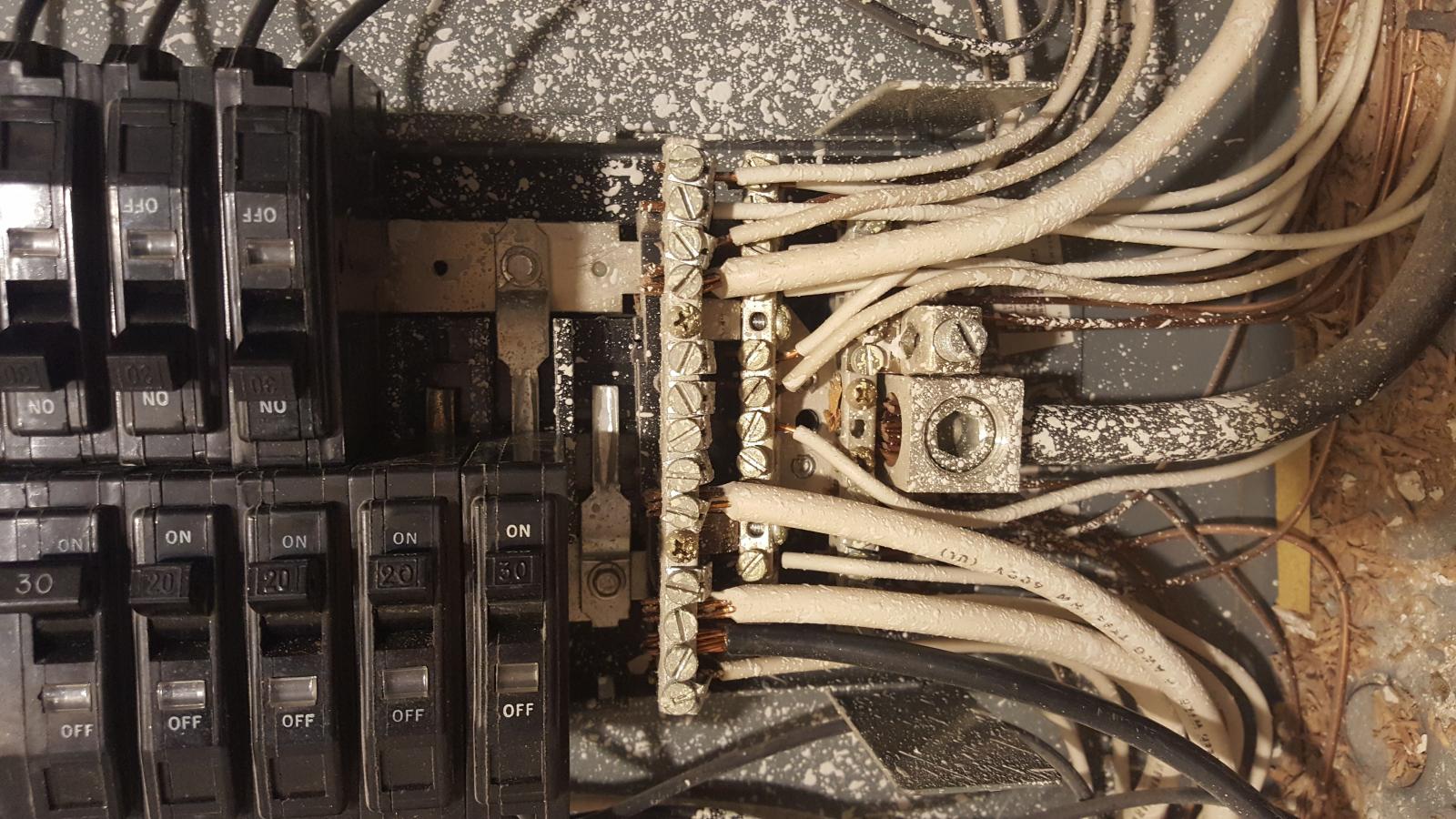

Thanks for you help as usual. I plan on climbing up and crawling all the way to the opposite side of the house and checking this out sometime this weekend. It is so hard to get back there. I am actually half afraid of what I might find. As far as the house goes the main house panel is not up to code either. The inspector told me it would have to be moved to an exterior wall and out of my master bedroom closet. It also needs to be replaced because it does not have a main breaker to kill "all circuits" which is a no-no too. And, code requires it to have "X" amount of space around it. So theoretically I can't hang cloths around it or use half of the closet. Yeah right...

Anyway, I really don't know if I can afford all of that at the moment. (maybe income tax)... I really just want to make beer again.

PS... Oh and I already found a splice job in the attic for the exhaust vent over the stove. My thought was to fix with a junction box. I am not sure how much slack I will have for this type of repair though. I am afraid I might find more the deeper I dig, like the new fans in the two bathrooms I noticed???

Thanks again,

Matt...

It sounds like you have some electrical upgrades in your future. Not having a service disconnect for your house panel is not a good sign. Unfortunately, if you're seeing other sketchy wiring about, you'll probably find more.

I would plan for upgrades when money allows. Don't let it stop you from brewing though. Build your brewery well and plug it into your shop panel with a gfci in between. The brewery won't need to be changed when the wiring gets updated. A three wire feed doesn't meet today's code but if you do things right, it doesn't spell instant death.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)