My family just thinks I am being cheap when I set the winter thermostat to 64F...Thanks ! I had a look at the chamber but I do not have so much space really. My space so far is under a sink and I will definitely brew with season. But my apartment is heated (around 70F) during the time I am here and a little bit colder during working hours.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1-Gallon Brewers UNITE!

- Thread starter JeffoC6

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

frenchbrewer

Well-Known Member

lol I'm fine with 64F at night or during daytime when I'm at work... but then if it's under 69F when I'm home my wife would not be happy...My family just thinks I am being cheap when I set the winter thermostat to 64F...

I tape the probe to the side of the jug and put some bubble wrap over it to provide some ambient protection, or use a bottle of water with the probe taped to that if I had more than one jug fermenting.I am seriously thinking about it but I cannot find a way to put the sensor in the jug cause I cannot find a cap with 2 holes for for thermowell and airlock.

How do you do it?

Regarding the heat mats can you just put it like that on a plywood cabinet or does it need any insulation?

A piece of foam board would help keep the heat moving toward the jugs but not really needed.

64 degrees is perfect for most ale yeast.

frenchbrewer

Well-Known Member

OK I may do that. I guess the reading should be accurate-ish on the long run just maybe with latency but the main purpose is to keep the temp stable correct?I tape the probe to the side of the jug and put some bubble wrap over it to provide some ambient protection, or use a bottle of water with the probe taped to that if I had more than one jug fermenting.

A piece of foam board would help keep the heat moving toward the jugs but not really needed.

As long as you are close you should fine.

I made beer for a couple years with no temp control in my garage, the beer came out just fine. If you can control the temp though that is not a bad thing.

I made beer for a couple years with no temp control in my garage, the beer came out just fine. If you can control the temp though that is not a bad thing.

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

Druman07

Well-Known Member

I can fit two jugs tightly in a minifrig, though there is not enough vertical room with the "freezer" for both to have a airlock, so the one with the blow off tube goes under the "freezer". I have found my beer has improved significantly and is more consistent since I moved to a frig, vs the ups and downs of my basement temperature, though no doubt the other solutions mentioned are viable but require a bit more attention from the brewer.

offenbeckerm

Member

- Joined

- Jan 9, 2013

- Messages

- 9

- Reaction score

- 4

Hello my 1 gallon people. Actually not sure what I am lol. Brand new to the site and brand new to the craft. My wife bought me a 1 gallon maple porter kit for Christmas, which i just made and went into fermentation yesterday. I really enjoyed the process and now am hating the anticipation lol. Gonna try a few batches in my gallon and may get a second one to ease the waiting times. I'm really enjoying this forum also. Lots of terrific stuff!

Just like Tom Petty said, the waiting is the hardest part. I do a "big" brew of 5 gallons about every 6 weeks, and I try to scatter in a few little brews of either 1 or 2.5 gallons in between. Right now, my fermenting room has two secondary ferments of mead (split from one initial batch for experimentation), a one-gallon from a week ago, and a 2.5 gallon from about 3 weeks ago. I'm at a point where I can poke my head in every day or two and do something or see some progress. It might be transferring to a secondary, adding some dry hops, tossing in some wood chips...whatever. It's a fun hobby. I'd suggest just staggering some batches. Eventually, you'll have enough so that the waiting won't be so bad!

Infantryjared1

Well-Known Member

- Joined

- Feb 1, 2019

- Messages

- 60

- Reaction score

- 36

Yeah, that's what I'm working towards. Got 2 gallons of cider now in 3 or four days of fermentation and will be starting a gallon of red ale this weekend. I know when i move up to 5 gallons I'm going to want to keg, so I'm studying up on that before i make the leap. I'm definitely enjoying it and will so even more when I have a tasty beverage. Cheers

offenbeckerm

Member

- Joined

- Jan 9, 2013

- Messages

- 9

- Reaction score

- 4

Yeah, that's what I'm working towards. Got 2 gallons of cider now in 3 or four days of fermentation and will be starting a gallon of red ale this weekend. I know when i move up to 5 gallons I'm going to want to keg, so I'm studying up on that before i make the leap. I'm definitely enjoying it and will so even more when I have a tasty beverage. Cheers

I keg a lot of my 2.5 gallon batches in smaller keg (I think it's 2.5 gallons?) that I bought. They're not that hard to find, but sadly they're no cheaper than a 5 gallon. They also have some great 1 gallon and even 64oz. systems as well. I don't have one yet, but it's on my want list. In a small batch like that, bottling is pretty easy as well, but I want one so I can force carbonate mead and cider that I've killed to back-sweeten.

Infantryjared1

Well-Known Member

- Joined

- Feb 1, 2019

- Messages

- 60

- Reaction score

- 36

I forget the website, I think it was KorneyKeg, or something real similar. Anyway, the sell 5 gallon kegs that have been converted to ball and lock for like 45 bucks. They're used and could be "ugly", dents and what have you, but all the reviews are great

Do any of you folks harvest yeast from the small batches? If I only use a third to half of a packet, does it make much sense to harvest that amount from the jugs?

I usually use my 1 gallon batches to ferment my next 5 gallon batch, but I don't know why you wouldn't. Dollars are still dollars...Do any of you folks harvest yeast from the small batches? If I only use a third to half of a packet, does it make much sense to harvest that amount from the jugs?

That’s kinda my thinking, it’s something I’ve just started reading into and wasn’t sure if it had diminished results at a lower pitch. Thanks!

That’s kinda my thinking, it’s something I’ve just started reading into and wasn’t sure if it had diminished results at a lower pitch. Thanks!

I have on several occasions poured my wort over a yeast cake. It’s a lot of work doing it that way though because when I do that, I bottle and brew on the same day.

Infantryjared1

Well-Known Member

- Joined

- Feb 1, 2019

- Messages

- 60

- Reaction score

- 36

You can brew 2 gallons with one pack of yeast, at least my HB store only sells them fit for 5 gallon. A few bucks for 2 guaranteed gallons of usable yeast, versus 20 bucks or so of ingredients is worth the piece of mind in my opinion. But, I'm also just starting out.

I keg a lot of my 2.5 gallon batches in smaller keg (I think it's 2.5 gallons?) that I bought. They're not that hard to find, but sadly they're no cheaper than a 5 gallon. They also have some great 1 gallon and even 64oz. systems as well. I don't have one yet, but it's on my want list. In a small batch like that, bottling is pretty easy as well, but I want one so I can force carbonate mead and cider that I've killed to back-sweeten.

I just bought a 1.75 gallon keg and a 24oz co2 paintball bottle (plus converter).

While bottling a 1 gallon batch is easier than a 5, I've got to say that being able to drink my beer the next day was amazing. No worries about bottle bombs, dealing with tabs, or having to wait another 3 weeks. And it fits in my garage fridge.

Attachments

I’ve looked at those smell kegs longingly myself. Someday!

PCSharkynose

Member

- Joined

- Jan 27, 2019

- Messages

- 9

- Reaction score

- 6

I did two batches today and now they are in fermentors doing their thing. One is a nut brown ale the other is a honey porter. Two weeks can't come soon enough.

edit... I think I can't add images because I don't have enough posts.

2nd edit... I figured out what I did wrong

Last edited:

BrewnWKopperKat

(Ο_Ο)

It was fun to hear about variations in the "Hop Sampler" process in the (Basic Brewing Radio) Feb 7, 2019 episode - replace Pilsen/light with Amber or Vienna.

I've also done some "hop steeps" this way. Rather than adding all the hops at "flame-out", let the wort cool to 180* F (or 170*, or ...) then add the hops (and keep the wort at 180* F) for 20 - 30 minutes.

Anyone else trying multiple hops? Perhaps Hop Stand vs. Dry Hop scaled to a gallon and converted to use extract+steep (and maybe cold steep)?

I've also done some "hop steeps" this way. Rather than adding all the hops at "flame-out", let the wort cool to 180* F (or 170*, or ...) then add the hops (and keep the wort at 180* F) for 20 - 30 minutes.

Anyone else trying multiple hops? Perhaps Hop Stand vs. Dry Hop scaled to a gallon and converted to use extract+steep (and maybe cold steep)?

Last edited:

I did two batches today and now they are in fermentors doing their thing. One is a nut brown ale the other is a honey porter. Two weeks can't come soon enough.

Those both look tasty! I think when my next order gets placed, one or both need to happen.

Looks like I’m acquiring a free mini fridge for the basement, anyone have a simple small batch lager recipe? Been dying to try one.

MotorcycleMatt

Well-Known Member

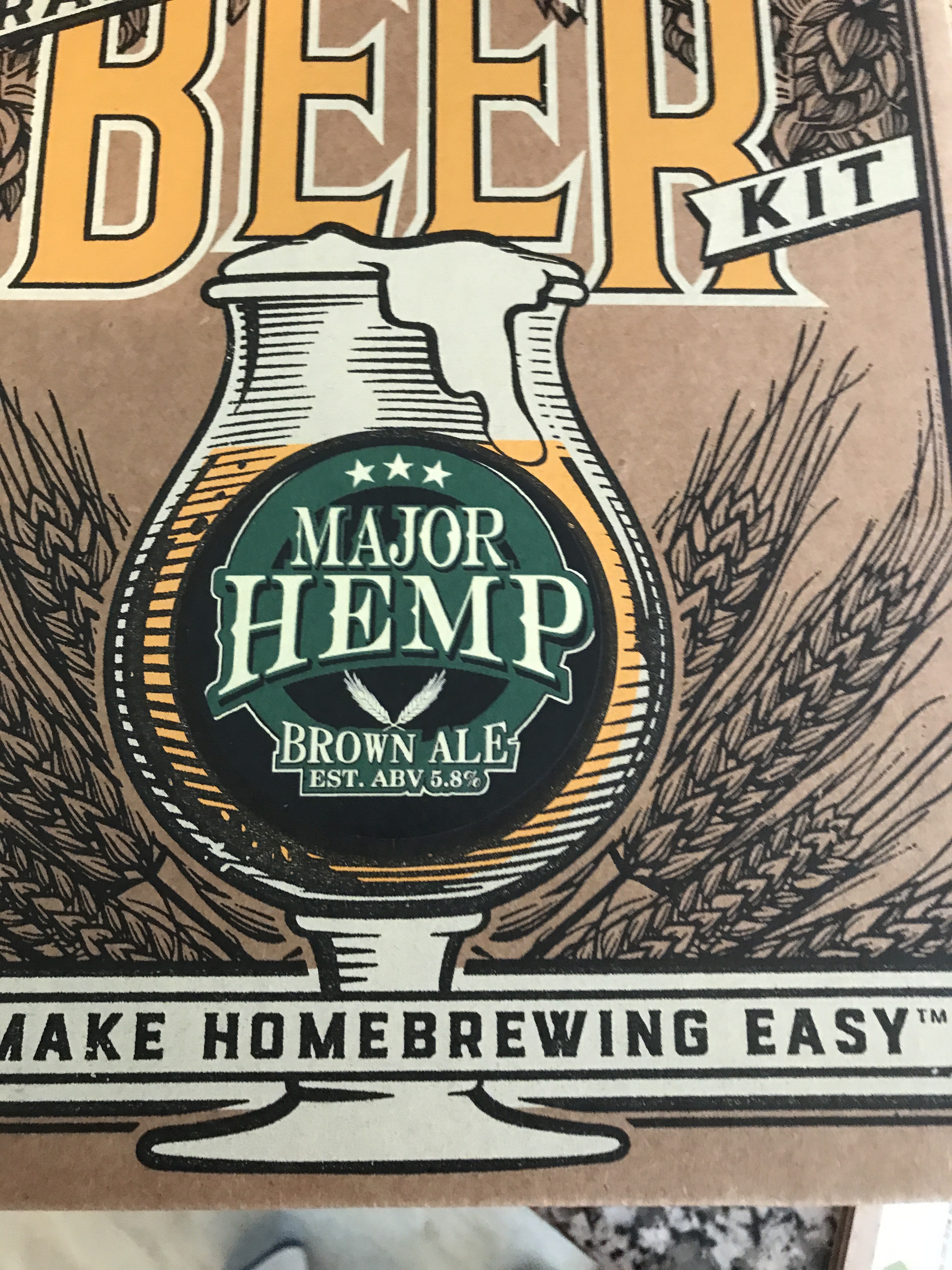

I picked up a cheapo 1 gal kit that was on clearance in target, heating up my mash water now. Looking forward to trying 1 gallon test batches before I scale up to my 5 gallon system

Infantryjared1

Well-Known Member

- Joined

- Feb 1, 2019

- Messages

- 60

- Reaction score

- 36

I dont have any temperature control right now for fermentation, other than a cold basement (not colder than 63 or so) so haven't looked into lagers. Have seen many recipes though on the recipe section of the forums. If I had one, I'd share it though. Cheers!

I have a keezer I built out of a 10 ft³ chest freezer with wooden collar, and a raspberry pi for temp control. Inside are 4 1.5 gal kegs and 2 2.5 gal kegs. Those 1.5s (morebeer.com stackable torpedo kegs) are some of my favorite things in the world.

I can brew a 3.5 gallon batch, split between 4 1-gallon fermenters with different dry hops or yeast, then keg them all and compare. Or try 3 different fermentation temps for the same batch at the same time, ruling out just about every variable but temperature.

I've done at least 20 1-gallon batches to compare variations when 'dialling in' my saison and my patersbier, plus several to address the "what if I brew 5 gallons of this and it sucks" worry.

1-gallon batches can be very finicky in ways (trying to get exactly 0.12oz bittering hops, for example) but can be very rewarding when you hit 'just right' and know you can easily scale it up to 3gal or 5gal.

(imho the biggest drawback in 1 gallon brews is that people always want to try my beer, and I hate having to explain "well, there's 6 bottles left of the latest")

j

I can brew a 3.5 gallon batch, split between 4 1-gallon fermenters with different dry hops or yeast, then keg them all and compare. Or try 3 different fermentation temps for the same batch at the same time, ruling out just about every variable but temperature.

I've done at least 20 1-gallon batches to compare variations when 'dialling in' my saison and my patersbier, plus several to address the "what if I brew 5 gallons of this and it sucks" worry.

1-gallon batches can be very finicky in ways (trying to get exactly 0.12oz bittering hops, for example) but can be very rewarding when you hit 'just right' and know you can easily scale it up to 3gal or 5gal.

(imho the biggest drawback in 1 gallon brews is that people always want to try my beer, and I hate having to explain "well, there's 6 bottles left of the latest")

j

I brewed my first lager (essentially a helles bock) a few months ago, sized to fit the 2.5 gallon destination keg. 65% pilsner malt, 35% munich malt, 24 IBU Magnum hops for full 60 min boil, fermented with WLP835 (Andechs, yeast vault) at 50°F in my keezer for about 20 days followed by 2 days at about 62°F then kegged and back into keezer now at 36-40°F.Looks like I’m acquiring a free mini fridge for the basement, anyone have a simple small batch lager recipe? Been dying to try one.

Came out delightful. OG 1.066 FG 1.011. Scaled to 1 gallon I'd go with 22oz pilsen malt, 12oz munich, and 0.1oz Magnum (or 24 IBU of your favorite bittering hop), mash between 150 and 152 for 60-75 mins, boil for 60 mins. For extract find one that is similar proportions of pilsner/munich (65/35) and target 1.065 OG.

j

Came out delightful. OG 1.066 FG 1.011. Scaled to 1 gallon I'd go with 22oz pilsen malt, 12oz munich, and 0.1oz Magnum (or 24 IBU of your favorite bittering hop), mash between 150 and 152 for 60-75 mins, boil for 60 mins. For extract find one that is similar proportions of pilsner/munich (65/35) and target 1.065 OG.

j

I’ll have to try something similar to this (or exactly!) when I get my fridge and next grain order going. Thanks for the advice

Biggest factors are to select a yeast you like, and chill wort to that yeast's optimal temperature before pitching. Then rest in low 60s for 2-3 days before packaging.I’ll have to try something similar to this (or exactly!) when I get my fridge and next grain order going. Thanks for the advice

j

Hmm okay. I’ve rummaged through various recipes and I have a very simple inventory at the moment. I really like seeing a basic grain bill to start with. Yeast will be an experimentation for a time, but maybe I’ll get lucky early

InspectorJon

Well-Known Member

Looks like I’m acquiring a free mini fridge for the basement, anyone have a simple small batch lager recipe? Been dying to try one.

https://www.beercraftr.com/1-gallon-san-diego-lager/

https://www.beercraftr.com/1-gallon-uncommon-lager/

https://www.beercraftr.com/1-gallon-boston-lager-recipe/

Divide any 5 gallon recipe by 5 works pretty well also. Use a gram scale to weigh hops and small amounts of specialty grains.

Similar threads

- Replies

- 55

- Views

- 3K

- Replies

- 22

- Views

- 2K

- Replies

- 16

- Views

- 1K

- Replies

- 4

- Views

- 1K

- Replies

- 18

- Views

- 2K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)