My typical batch sizes are 1.25 and 2.5 gallons, which I do in an SS Brewtech Mini (5.5 gallon) kettle on my stovetop. (I also do the occasional much smaller batch, but use a different setup for that.)

For the 2.5-gallon batches, I usually drop 5 F over a 60-minute mash, which I've never loved, but it didn't seem

too bad, and seemed to still make good beer. In the past week I've been taking a closer look -- that is, frequent temperature measurements during the mash -- and the picture is not a pretty one. It turns out the temperature first goes

up by about 4 F over 10-20 minutes, then drops 9 from there. I'm using a glass-top radiant range, so clearly there's a lot of thermal input even after the heat is turned off.

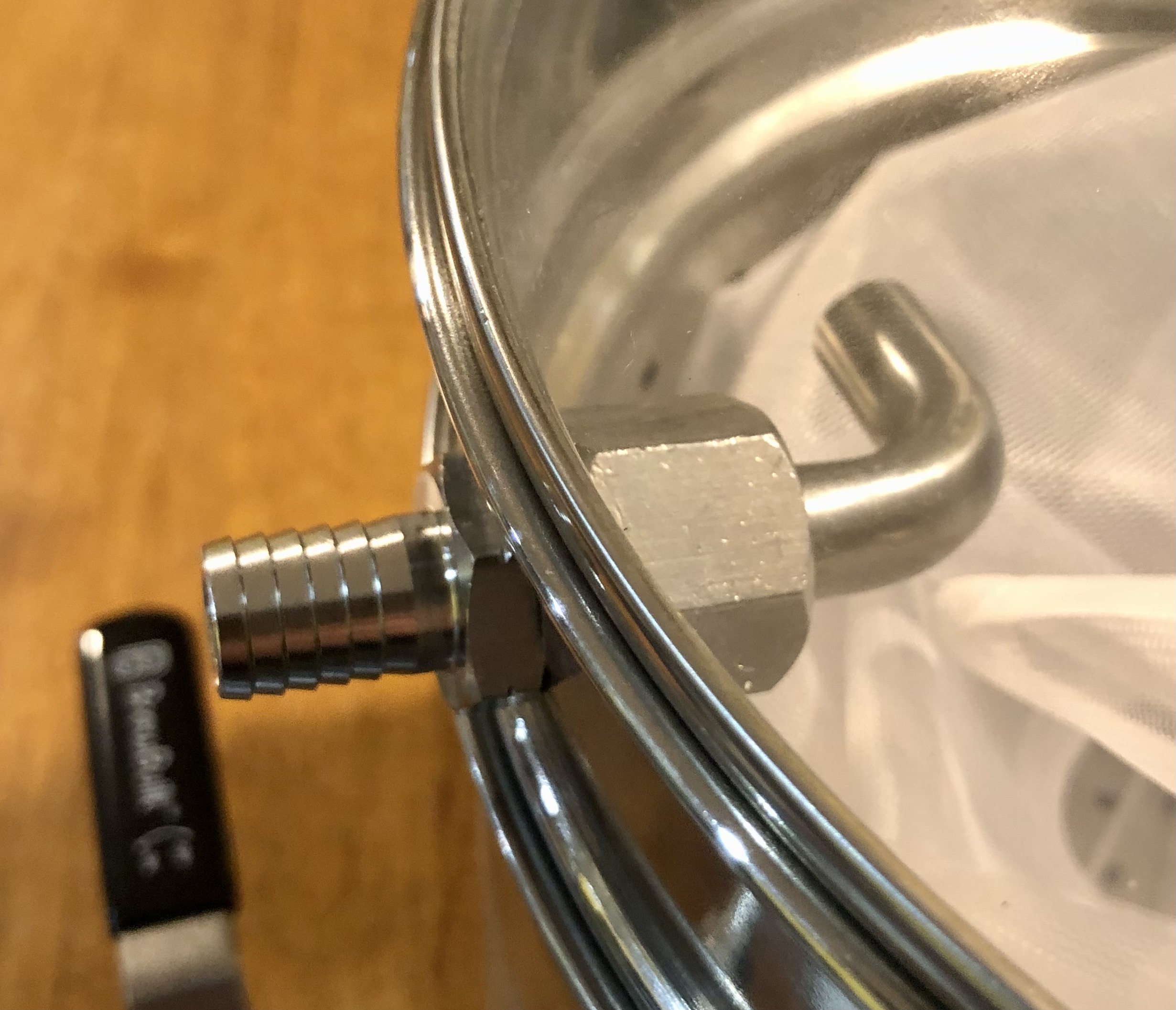

Here is my solution:

View attachment 865905

I had to muscle it on to my kettle (which is pretty svelte, even for 5 gallons), but it fits well -- so check your dimensions!

I still use my stovetop to get to strike temperature, but then I place the kettle onto an insulated trivet, and turn this thing on. It took some fiddling, but I was able to hold mash temperature at +/- 1 degree, measured every 10 minutes for a 90-minute mash. I've only done it twice so far, so it could get even better once I figure out the details.

It's thermostatted, which might be a good thing, or might not. I'm thinking I might try turning that thermostat all the way up so that it's always on, then using a variable-AC supply I have.