Baja_Brewer

Well-Known Member

Hi All,

Been here on and off for a number of years now. I started homebrewing after my freshman year in college (relax, I lived in Canada) and kept it up for about two and a half years and 30-35 batches. At that point I transferred to a school in the US and brought some of my gear back with me. I made a few bad batches, buckled down in school, and then sold a ton of my gear to fund a summer off on my motorcycle - this included my grain mill, mash tun, boil kettle, burner, a bunch of kegs (should have kept tho$e)

Told myself I'd get back into it after school, but instead I got a full time job, a project car, and started grad school Kept the job, haven't finished the car (its close, I swear :cross

Kept the job, haven't finished the car (its close, I swear :cross , and finished grad school - and started feeling like I'm never going to have any free time to get back into brewing.

, and finished grad school - and started feeling like I'm never going to have any free time to get back into brewing.

Like many here I sold my soul to be an engineer - so what if I build myself an automated homebrewing system?! Yeah, like I have time for THAT! But seriously, I want to be a grand brewmaster someday. I need to invest my 10k hours somehow, right? Enter the picobrew.

As far as I can tell - there are three camps for the Picobrew:

1) the "never in 1,000 years - standing over a HLT trying to hit your strike water temperature that you've calculated from the amount of grain, water you intend to use, ambient temperature and intended mash temperature is the only way you'll ever learn make good beer" camp.

2) the "I'd buy one, but its too expensive" crowd.

3) the "yup, I'm buying one!" traitors.

Now, for the same reason I don't exclusively listen to/read/watch CNN, NPR, or Fox News - I am a little bit of all of those. AND I bought a Picobrew. I want control and records for my brews, without standing around with a thermometer in my hand.

I made it into the end of the "pre-order" session in January 2015 after I knew that the product was actually shipping and I had read enough feedback to learn that the machine wasn't a complete piece of garbage - and I was stoked to get it. They've stepped up their production, and I had mine within 2 months of ordering, receiving a tentative shipment date of a few weeks after someone who had pre-ordered in October or November. Not bad!

So I received it yesterday, March 7, 2015, and my second brew is currently underway. First impression? Wow - impressive piece of equipment. No way anyway could have built anything a quarter of caliber in less than hundreds of hours of design, component selection, fabrication and software writing. I think the designers went through 3 prototypes? Very solid, and cool.

I had the option of plugging it into ethernet or connecting to my Wi-Fi (no brainer) and it it was already tied to my Picobrew account - which is assigned when you're assigned a unit production number. I did that, thought I did a rinse, and then proceeded to dial up the Pico Pale Ale kit they provided. I tweaked the recipe for slightly higher IBU's, synced the recipe to my Pico- and was off!

Well not quite, the mash wasn't holding temperature and the mash tun part of the step filter wasn't filling with water. WTF Picobrew? Relax - its probably my fault and.... yep! The oring I put on the keg while rebuilding it was too small - air was getting pulled in while the pump tried to pull the wort/water in - so I wasn't getting a full flow. Whoops.

Fix that and try again :cross:

I actually fell asleep during the boil!

Cleanup took about 25 minutes since I tried to do the machine's rinse with the mash tun still full (hint, empty it) and had to re-do the rinse. I did a no chill brew - opting to drain the machine after the chill alarm sounded to hook up a wort chiller, and stuck the keg in a snow bank while I cleaned, moving it to the basement before bed. I pitched the yeast this morning, and we'll see how it turns out!

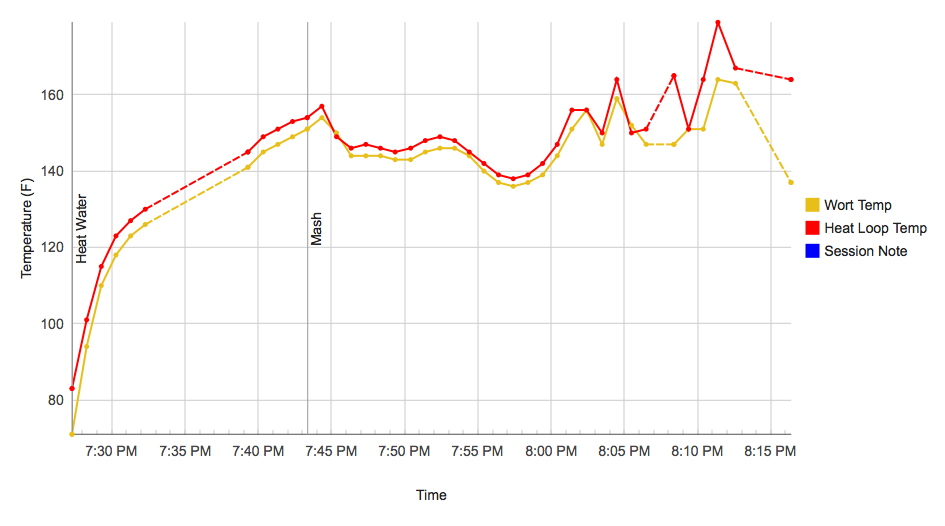

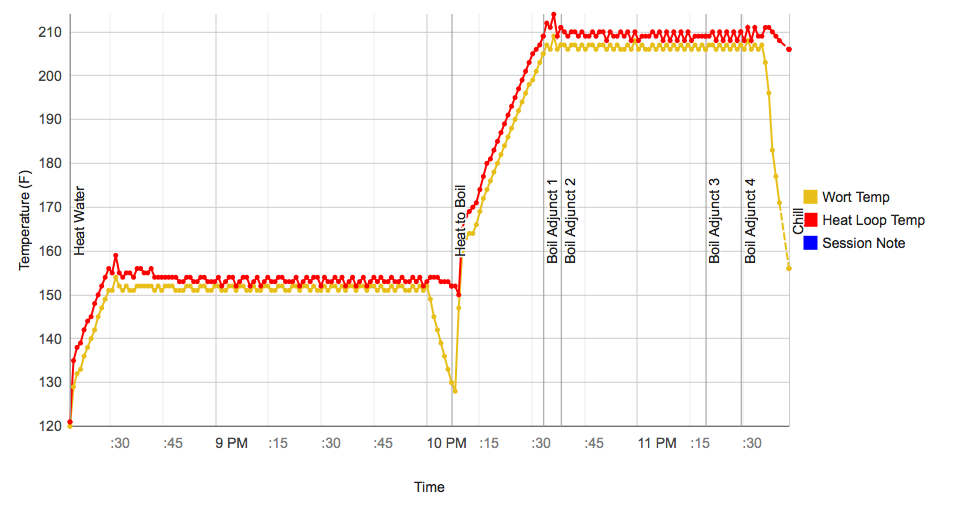

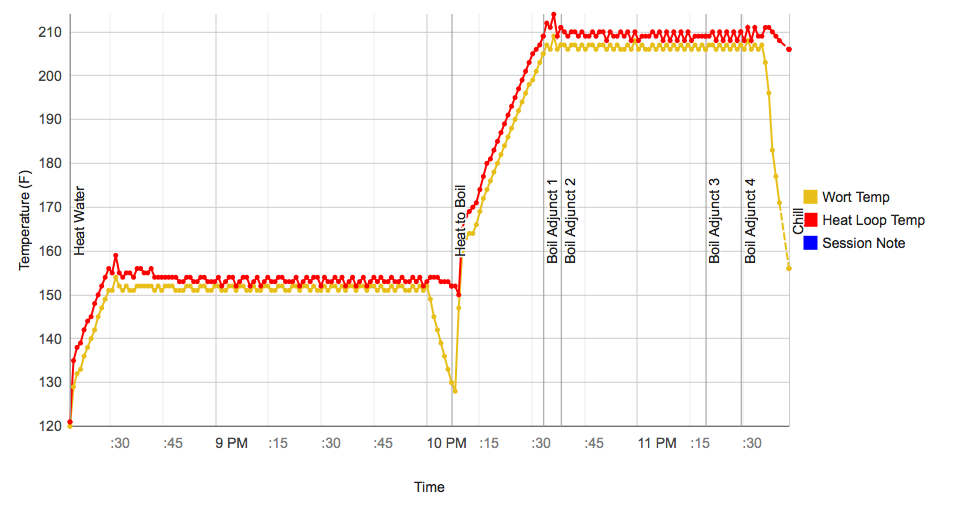

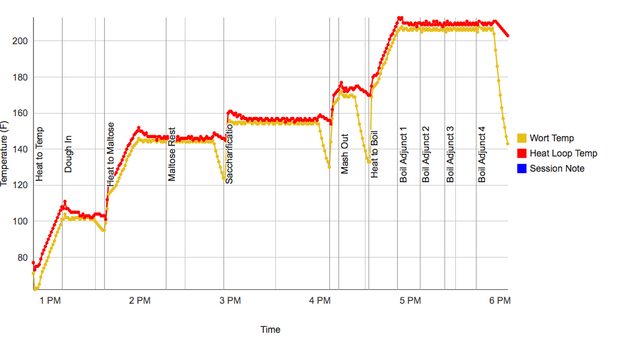

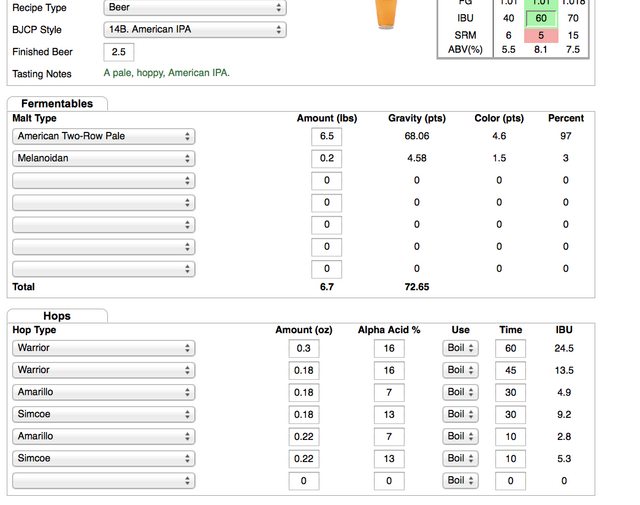

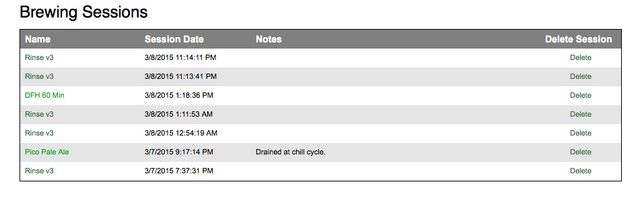

My intentions for the Picobrew, and this thread, are to make as much good beer as possible. I'm a huge data geek- so the brewing logs/plots (above) are a big sell for the Picobrew. I'm brewing three batches this weekend including the Pico Pale and two of my former favorite clones (DFH 60 Min IPA and Bell's Two Heart) - Right now is the perfect time to ferment in the common area of the house, but I have all of the parts to build a BrewPi Fermentation Controller, which I will use with my mini-fridge kegerator (fits two kegs) as a fermentation chamber/cooler, and a seed germination mat as a heater. The BrewPi will also give me the ability to log fermentation temperatures, thus nearly completing the grain to glass data log. I'm currently planning on doing closed vessel transfers to minimize oxidation for secondary/carbinating - and bottling from the keg. We'll see how long that last actually happens.

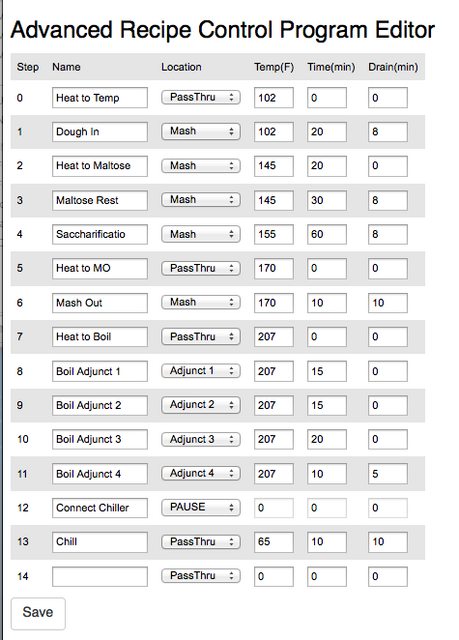

The Picobrew is currently in the middle of ramping to a Maltose rest - and its warm out, so I'm going to go walk the dogs! I'll post the temperature chart and a bit on the Picobrew advanced recipe control editor later once this brew has completed!

Been here on and off for a number of years now. I started homebrewing after my freshman year in college (relax, I lived in Canada) and kept it up for about two and a half years and 30-35 batches. At that point I transferred to a school in the US and brought some of my gear back with me. I made a few bad batches, buckled down in school, and then sold a ton of my gear to fund a summer off on my motorcycle - this included my grain mill, mash tun, boil kettle, burner, a bunch of kegs (should have kept tho$e)

Told myself I'd get back into it after school, but instead I got a full time job, a project car, and started grad school

Like many here I sold my soul to be an engineer - so what if I build myself an automated homebrewing system?! Yeah, like I have time for THAT! But seriously, I want to be a grand brewmaster someday. I need to invest my 10k hours somehow, right? Enter the picobrew.

As far as I can tell - there are three camps for the Picobrew:

1) the "never in 1,000 years - standing over a HLT trying to hit your strike water temperature that you've calculated from the amount of grain, water you intend to use, ambient temperature and intended mash temperature is the only way you'll ever learn make good beer" camp.

2) the "I'd buy one, but its too expensive" crowd.

3) the "yup, I'm buying one!" traitors.

Now, for the same reason I don't exclusively listen to/read/watch CNN, NPR, or Fox News - I am a little bit of all of those. AND I bought a Picobrew. I want control and records for my brews, without standing around with a thermometer in my hand.

I made it into the end of the "pre-order" session in January 2015 after I knew that the product was actually shipping and I had read enough feedback to learn that the machine wasn't a complete piece of garbage - and I was stoked to get it. They've stepped up their production, and I had mine within 2 months of ordering, receiving a tentative shipment date of a few weeks after someone who had pre-ordered in October or November. Not bad!

So I received it yesterday, March 7, 2015, and my second brew is currently underway. First impression? Wow - impressive piece of equipment. No way anyway could have built anything a quarter of caliber in less than hundreds of hours of design, component selection, fabrication and software writing. I think the designers went through 3 prototypes? Very solid, and cool.

I had the option of plugging it into ethernet or connecting to my Wi-Fi (no brainer) and it it was already tied to my Picobrew account - which is assigned when you're assigned a unit production number. I did that, thought I did a rinse, and then proceeded to dial up the Pico Pale Ale kit they provided. I tweaked the recipe for slightly higher IBU's, synced the recipe to my Pico- and was off!

Well not quite, the mash wasn't holding temperature and the mash tun part of the step filter wasn't filling with water. WTF Picobrew? Relax - its probably my fault and.... yep! The oring I put on the keg while rebuilding it was too small - air was getting pulled in while the pump tried to pull the wort/water in - so I wasn't getting a full flow. Whoops.

Fix that and try again :cross:

I actually fell asleep during the boil!

Cleanup took about 25 minutes since I tried to do the machine's rinse with the mash tun still full (hint, empty it) and had to re-do the rinse. I did a no chill brew - opting to drain the machine after the chill alarm sounded to hook up a wort chiller, and stuck the keg in a snow bank while I cleaned, moving it to the basement before bed. I pitched the yeast this morning, and we'll see how it turns out!

My intentions for the Picobrew, and this thread, are to make as much good beer as possible. I'm a huge data geek- so the brewing logs/plots (above) are a big sell for the Picobrew. I'm brewing three batches this weekend including the Pico Pale and two of my former favorite clones (DFH 60 Min IPA and Bell's Two Heart) - Right now is the perfect time to ferment in the common area of the house, but I have all of the parts to build a BrewPi Fermentation Controller, which I will use with my mini-fridge kegerator (fits two kegs) as a fermentation chamber/cooler, and a seed germination mat as a heater. The BrewPi will also give me the ability to log fermentation temperatures, thus nearly completing the grain to glass data log. I'm currently planning on doing closed vessel transfers to minimize oxidation for secondary/carbinating - and bottling from the keg. We'll see how long that last actually happens.

The Picobrew is currently in the middle of ramping to a Maltose rest - and its warm out, so I'm going to go walk the dogs! I'll post the temperature chart and a bit on the Picobrew advanced recipe control editor later once this brew has completed!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)