Hey all,

I just recently decided to upgrade my all grain setup with the addition of a plate chiller and chugger pump. BrewHardware had a great kit/setup for sale that took a little customization for my configuration, but was probably the best bang for the buck out there. Since I saw a few partial guides to setting up a pump and chiller like this, I figured I'd do the full DIY here.

So, step 1 is to source all the parts you need to make the switch box:

I chose to use a 14ga workshop replacement cord, generic light switch, weatherproof switch and plug cover, GFCI outlet, and a 7 port 2-gang box. I thought I would need wire twists, but it turns out you don't so ignore those. Cost was probably around $30-40 for all the parts, with the GFCI socket being the most expensive ($18 at my local lowes).

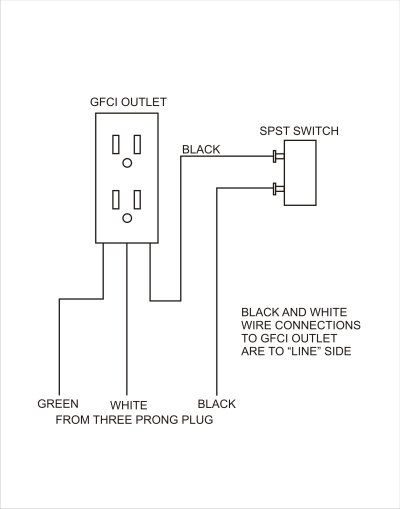

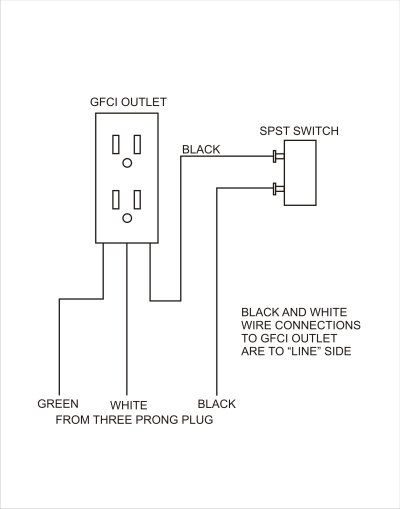

User day_tripper has a great wiring guide in this post:

https://www.homebrewtalk.com/f11/march-pump-wiring-switch-outlet-310309/#post3859204

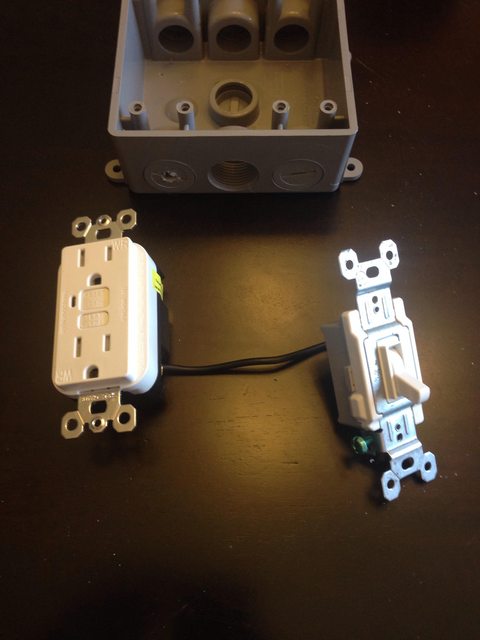

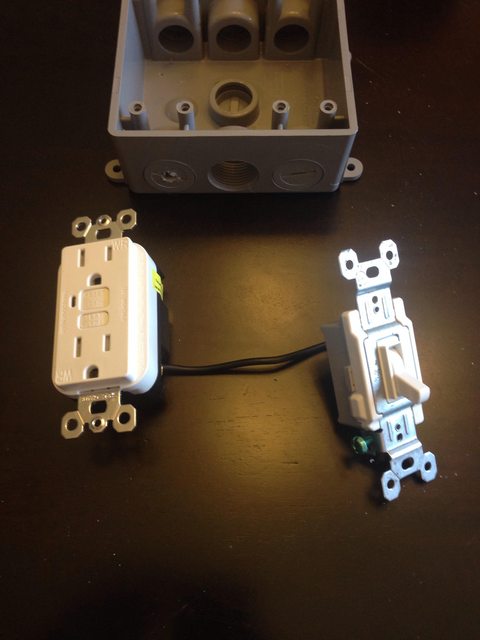

First step is to wire the switch and outlet together:

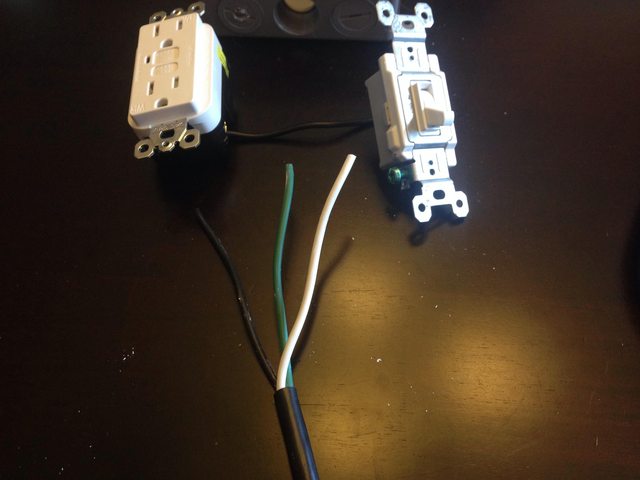

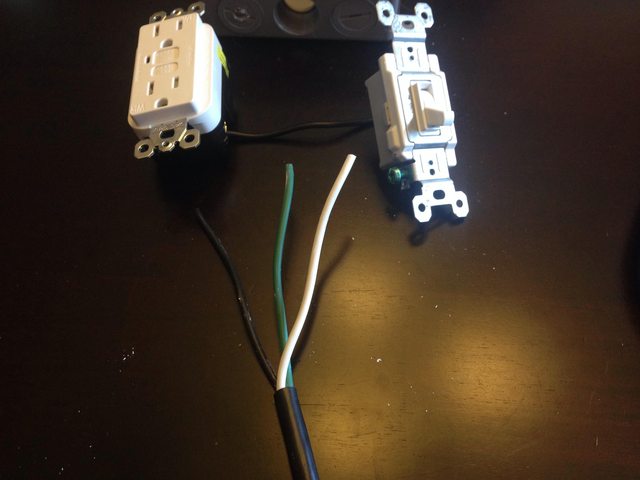

Then take a good few inches off the end of your workshop replacement cord to expose the three wires (green, white, black). Strip 1/4-1/2" from the end of each of the colored wires. Thread this through your gang box through one of the ports. This is important as all the wiring will be done in the box now.

As in the above diagram, green to ground, white to white. Not shown is black to switch.

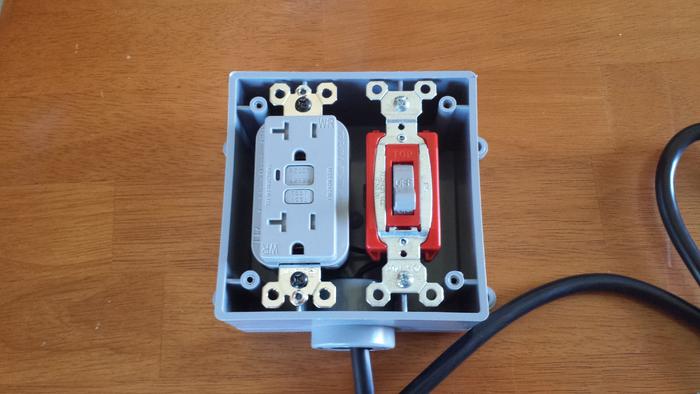

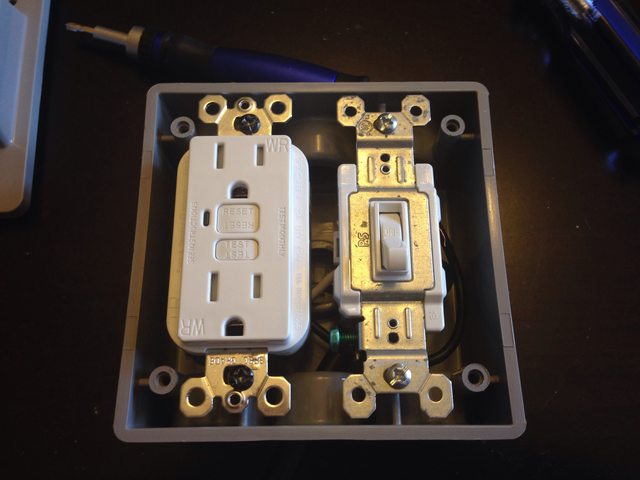

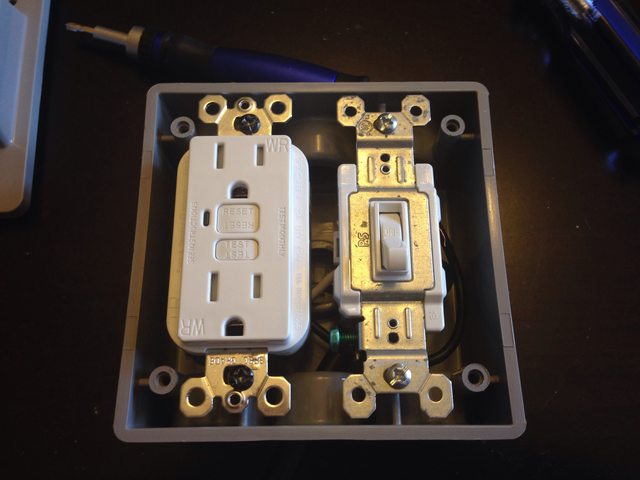

Screw the switch and GFCI outlet ports down in your box:

Before bolting everything else together, do a quick test to make sure that everything is working. I plugged in my fermentation heater to do a quick test to make sure everything worked. The switch should turn all power off to the outlets, and then also pressing the test button on the outlet should pop the "reset" button and turn on the indicator light.

Screw your cover down, making sure the seals are compressed and the outlet is centered in the hole so the cover seals properly. Make sure you take note of what position the switch is in, and what position on and off are.

The cover even came with some nice on/off stickers:

Mount to your brew station/stand/portable setup/etc:

Plug everything in and test for leaks/etc:

Congrats, you now have a portable GFCI switchbox for your pump setup. Typically outdoor sockets should be GFCI, but this way you can plug into anywhere and know you wont zap yourself if there is a leak.

I'll be ordering a HDPE board to mount this on eventually, as the wood would take a bunch of polyurenthane to seal and prevent water damage. HDPE is easier to maintain in the long run, but more expensive up front.

Hope you enjoyed, and please note I'm not a certified electrician...so do this at your own risk.

I just recently decided to upgrade my all grain setup with the addition of a plate chiller and chugger pump. BrewHardware had a great kit/setup for sale that took a little customization for my configuration, but was probably the best bang for the buck out there. Since I saw a few partial guides to setting up a pump and chiller like this, I figured I'd do the full DIY here.

So, step 1 is to source all the parts you need to make the switch box:

I chose to use a 14ga workshop replacement cord, generic light switch, weatherproof switch and plug cover, GFCI outlet, and a 7 port 2-gang box. I thought I would need wire twists, but it turns out you don't so ignore those. Cost was probably around $30-40 for all the parts, with the GFCI socket being the most expensive ($18 at my local lowes).

User day_tripper has a great wiring guide in this post:

https://www.homebrewtalk.com/f11/march-pump-wiring-switch-outlet-310309/#post3859204

First step is to wire the switch and outlet together:

Then take a good few inches off the end of your workshop replacement cord to expose the three wires (green, white, black). Strip 1/4-1/2" from the end of each of the colored wires. Thread this through your gang box through one of the ports. This is important as all the wiring will be done in the box now.

As in the above diagram, green to ground, white to white. Not shown is black to switch.

Screw the switch and GFCI outlet ports down in your box:

Before bolting everything else together, do a quick test to make sure that everything is working. I plugged in my fermentation heater to do a quick test to make sure everything worked. The switch should turn all power off to the outlets, and then also pressing the test button on the outlet should pop the "reset" button and turn on the indicator light.

Screw your cover down, making sure the seals are compressed and the outlet is centered in the hole so the cover seals properly. Make sure you take note of what position the switch is in, and what position on and off are.

The cover even came with some nice on/off stickers:

Mount to your brew station/stand/portable setup/etc:

Plug everything in and test for leaks/etc:

Congrats, you now have a portable GFCI switchbox for your pump setup. Typically outdoor sockets should be GFCI, but this way you can plug into anywhere and know you wont zap yourself if there is a leak.

I'll be ordering a HDPE board to mount this on eventually, as the wood would take a bunch of polyurenthane to seal and prevent water damage. HDPE is easier to maintain in the long run, but more expensive up front.

Hope you enjoyed, and please note I'm not a certified electrician...so do this at your own risk.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)