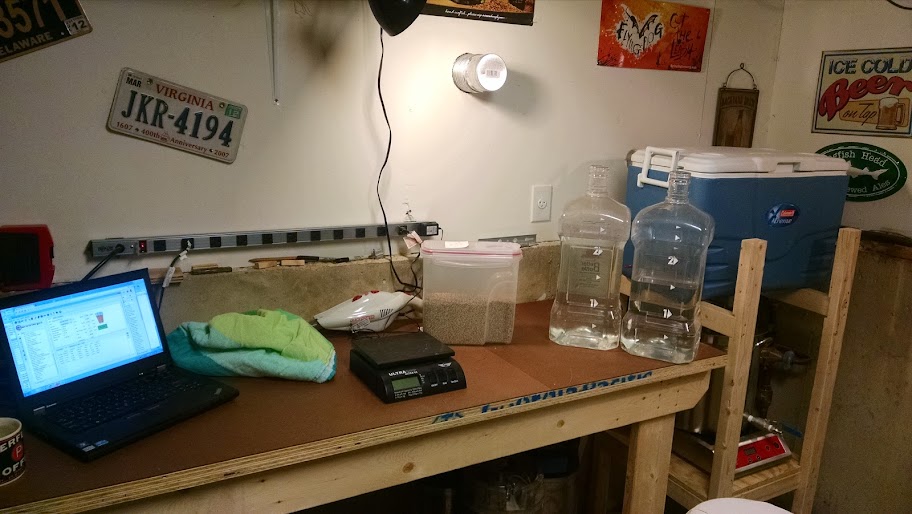

Didn't feel like starting another new thread document the remaining parts of my basement brewery build, so I will be putting them here!

Yesterday I

FINALLY got time to tackle installing the utility sink in my basement. I had multiple hours here and there, but yesterday was the first full day I could allocate to this and good thing, cause I needed the whole day!

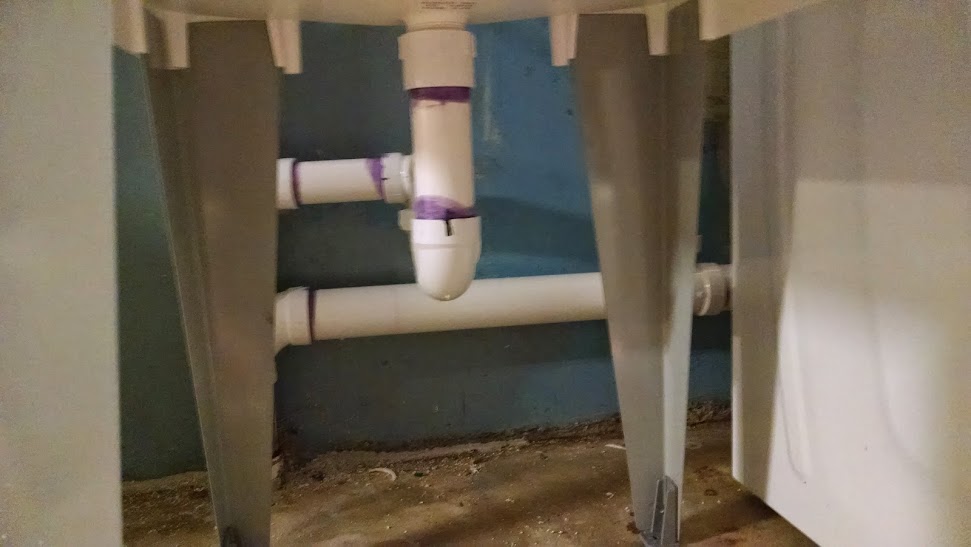

My existing plumbing in basement only had a laundry standpipe and hot/cold water. The laundry standpipe also wasn't up to code as the pipe was 2" but the p-trap and other piping was 1 1/2". I redid the standpipe and added a new vent connection to meet code - and more importantly not have the laundry siphon out my the p-trap on the sink

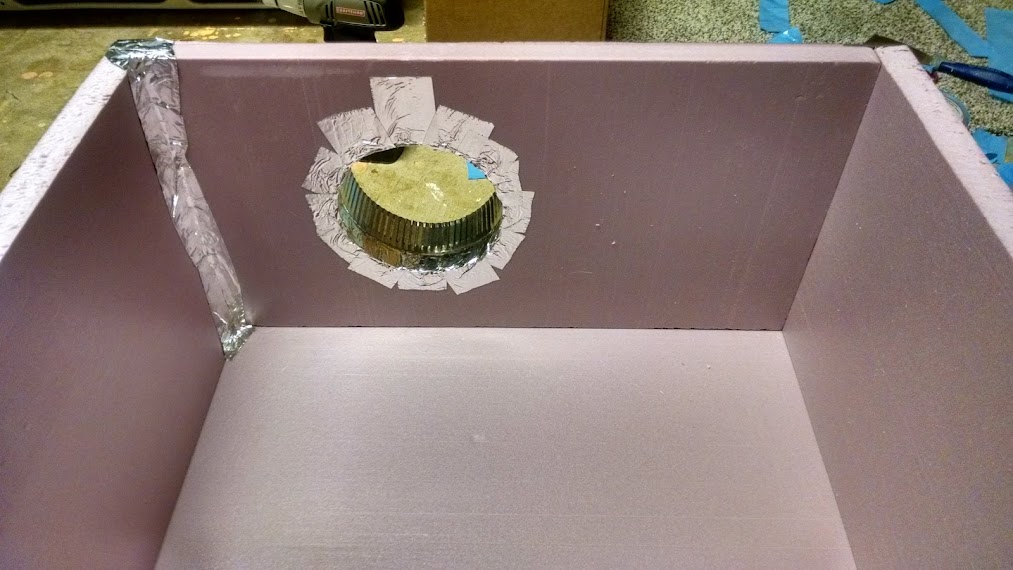

First, I turned off the water. Public Service Announcement - make sure to exercise (turn off and on) your gate stop valves on your water lines a few times a year. A few were REALLY hard to loosen. I then started to cut into the top pipe and my pipe cutter was walking all around on me and almost "threading" the pipe. Not sure if it was just a dull cutting blade or if its done. Regardless, trip 1 to the hardware store was made to get a new pipe cutter. I then got back and cut the pipe, cleaned and soldered in my fittings. I used tin foil held up by a metal thumb tack to prevent from burning my walls and/or house down - worked really well. I could have had some really nice solder joints, but I was scared the little bit of solder didn't make a good seal so I melted on more than I should have (probably totally unnecessary).

Soldered new pipe

Here is a pic of some cleaned pipe

Then I added two 45 degree fittings in alternating directions to extend me away from the wall and over the cement foundation wall.

Then I began the vent and drain piping. I started with a normal hand saw, moved to a hack saw and then remembered I had a little multi-tool. That thing is a life saver! Towards the end I was getting pretty good at making even cuts. You can barely see the laundry standpipe behind the machine, but its there. I actually had to make trip number 2 to the hardware store (right before Home Depot closed on a Sunday night) to get a slip joint and more 2" pipe for an extender for the standpipe since I had only purchased 2' sections #smallCarProblems.

Laundry standpipe and venting installed:

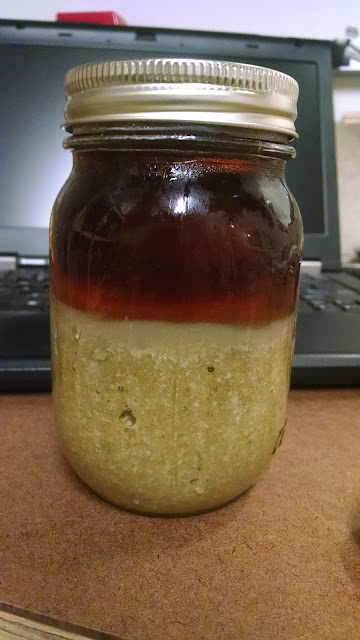

I then measured everything for the sink and glued it up. Had to be more precise here. I end up gluing the stub out and one part of the p-trap, then the sink tub and the other part of the p-trap. Everything fit perfect so I was able to slip the trap underneath and tighten it down.

Laundry drain front view:

Laundry drain side view:

Im thinking to myself, "Awesome I'm done just need to connect the supply hoses to the shut-off valves...Oh crap! I didn't buy 2 of the same hoses like I thought I did. Hardware store is closed, oh well." So I plan on going to get the correct hose tonight. I did check it with the one hose and worked and no leaks! Wife also did some laundry this morning with no issues. I call this a success!

Another Angle. You can see the 45s on the water pipes better.

Now I just need to installing my venting solution for the boil and can make some beer!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)