Redtab78

Well-Known Member

Well, when I say Giant, I documented the entire thing just in case someone else like me enjoys seeing what others do and how they do it.

Having that said, lets get to it!!

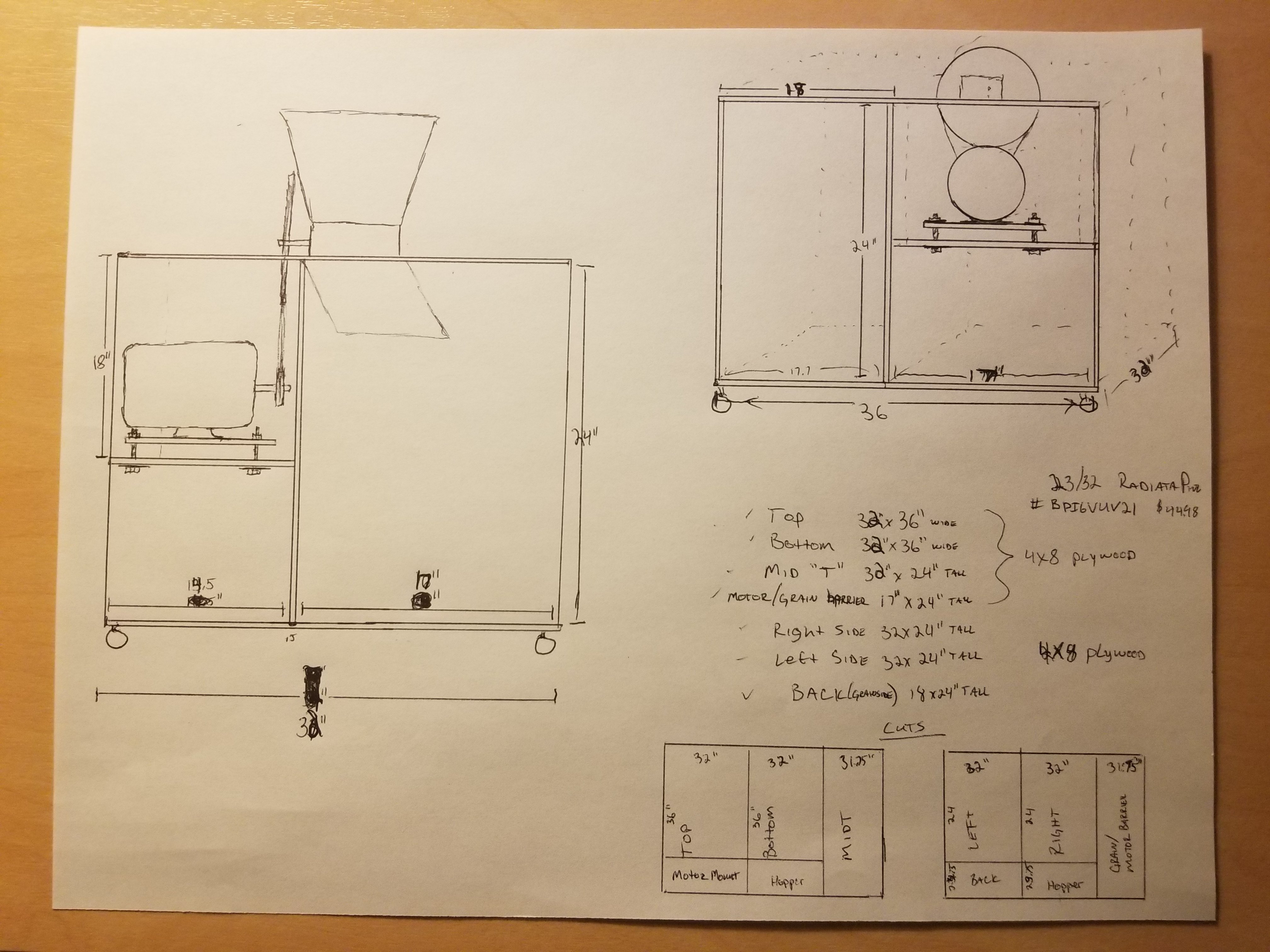

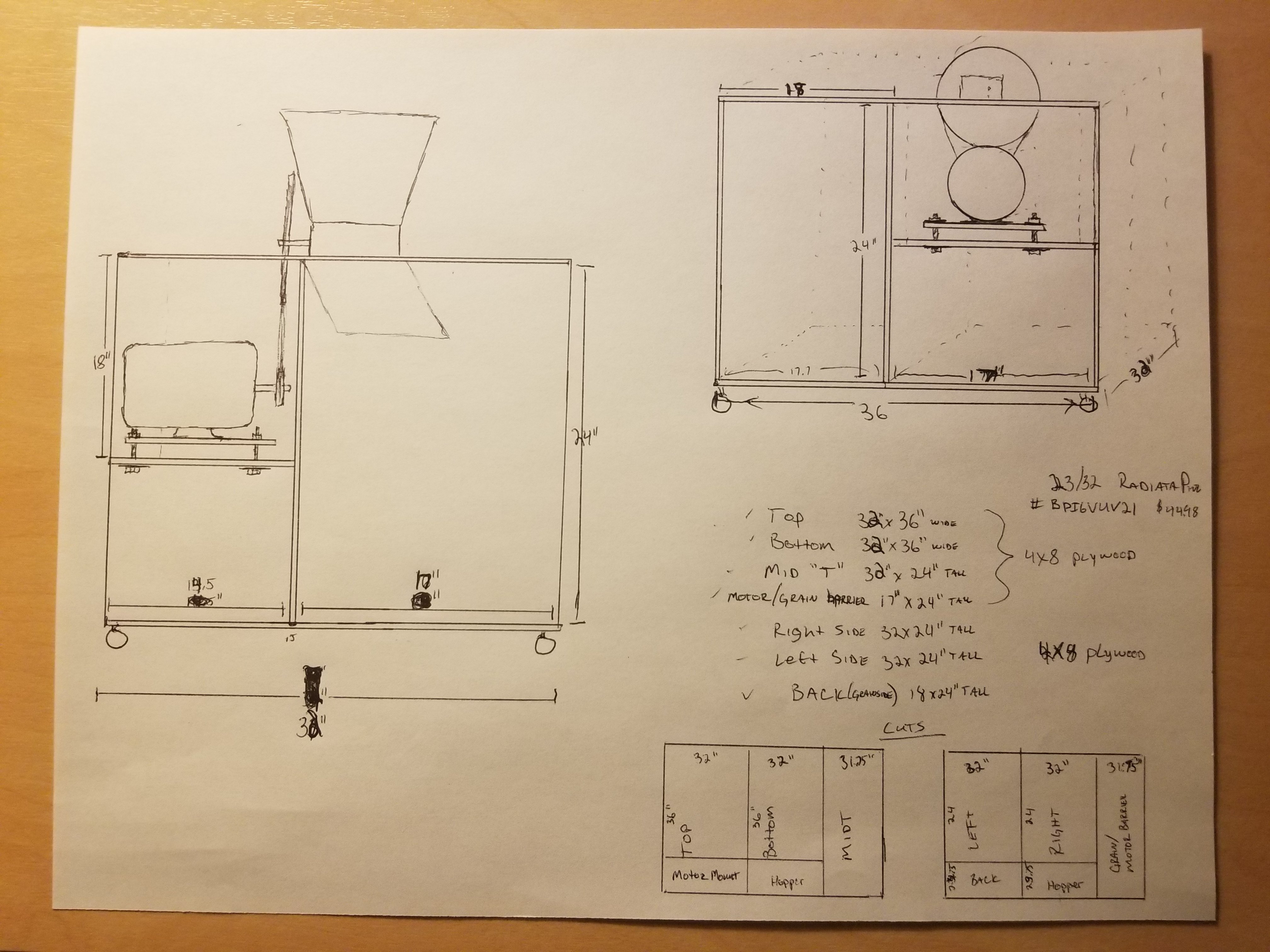

Here is the original design:

Even though the cutlist shows 2 full 4x8 sheets being used, I actually didnt all of both pieces, and I have about 1/3rd of a sheet left over that I plan to use later for another add on. After getting both sheets cut at 32" at Home Depot, (mostly had them cut it so it would fit in my jeep)

I made my first cuts, which was the bottom and the middle divider between what will later become storage and the milling area:

Using my handy dandy Kregg jig, I glued and pocket holed all joints:

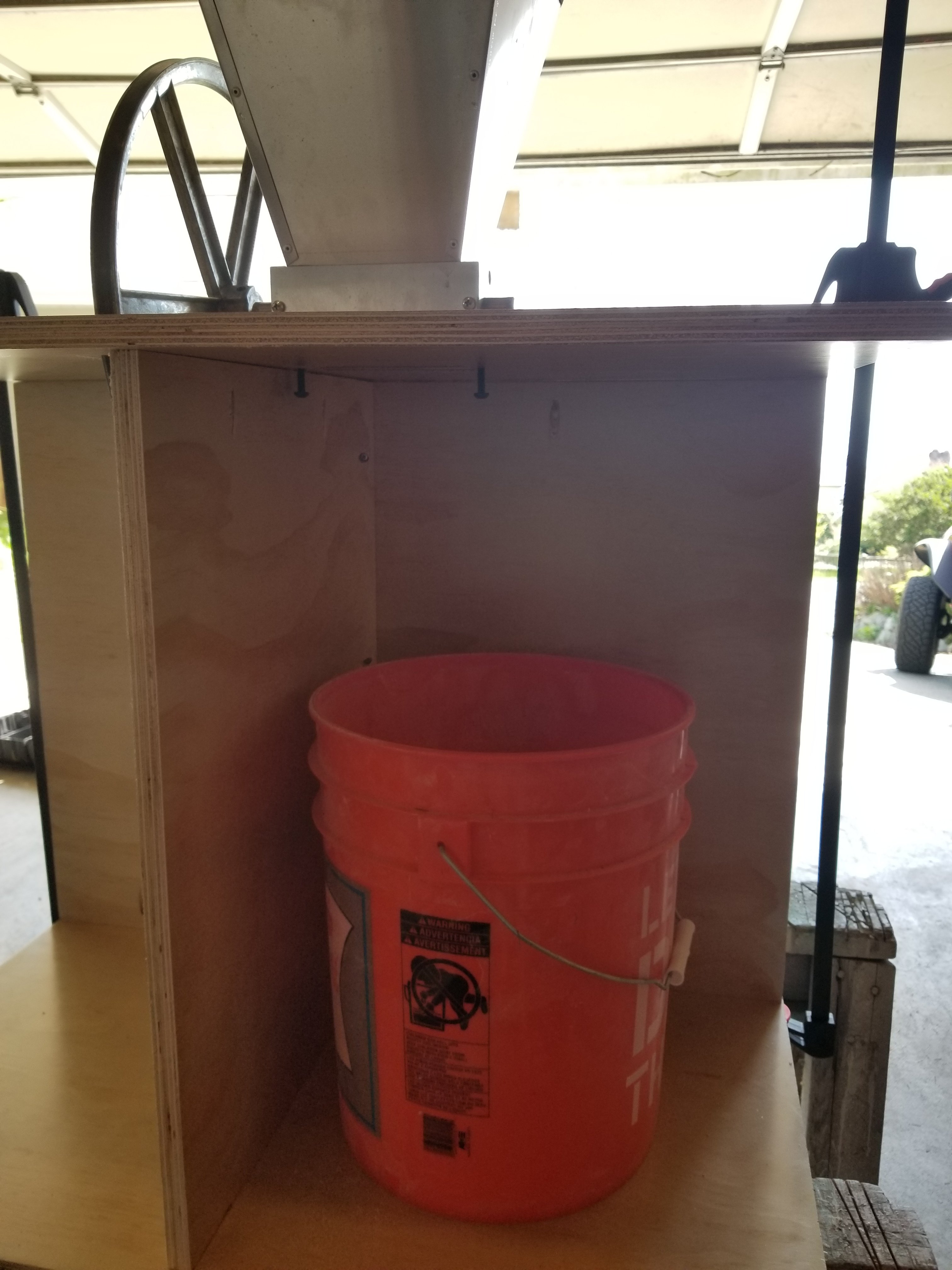

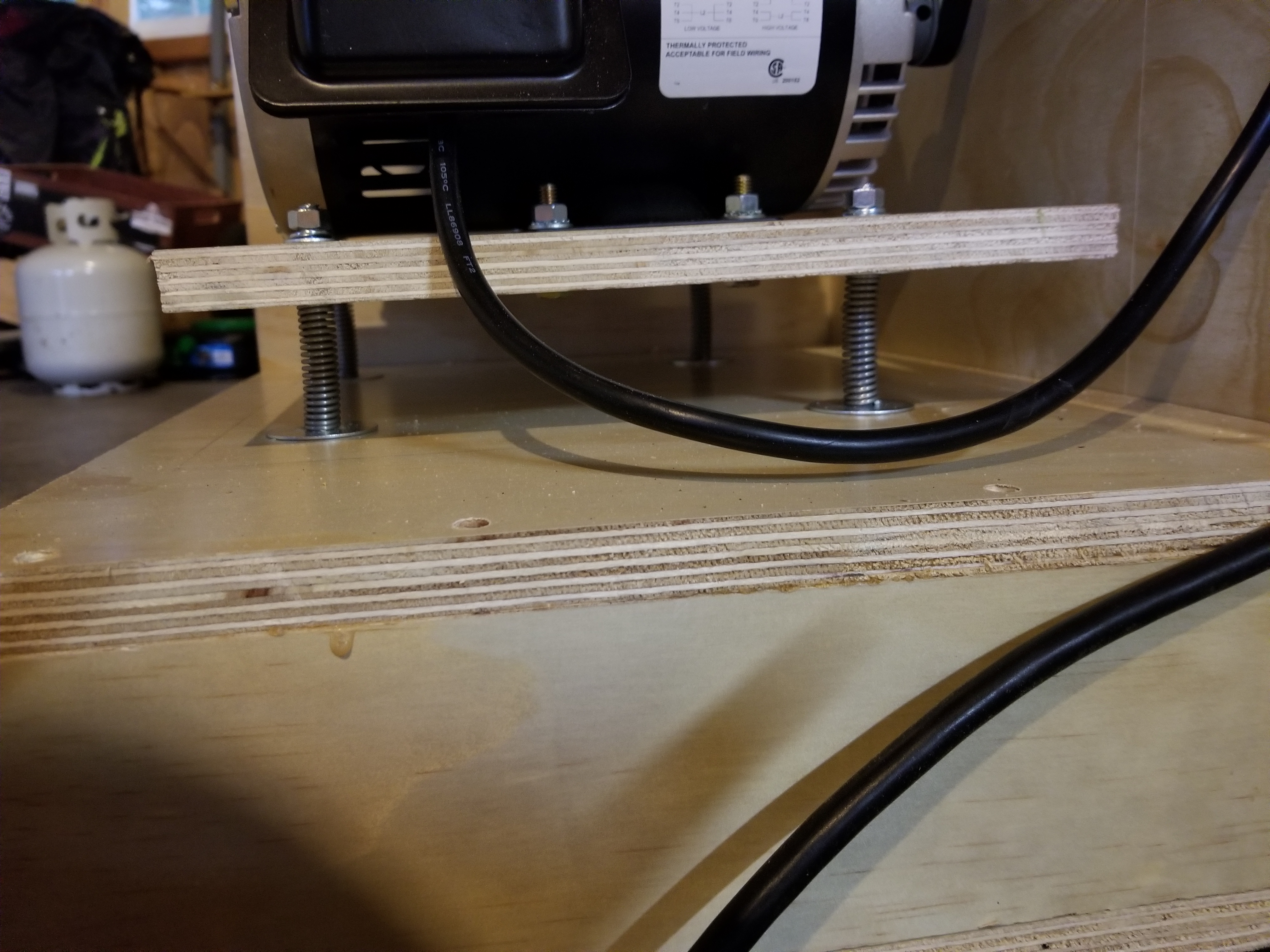

Next was the dividing wall between the motor and my catch bin:

Having that said, lets get to it!!

Here is the original design:

Even though the cutlist shows 2 full 4x8 sheets being used, I actually didnt all of both pieces, and I have about 1/3rd of a sheet left over that I plan to use later for another add on. After getting both sheets cut at 32" at Home Depot, (mostly had them cut it so it would fit in my jeep)

I made my first cuts, which was the bottom and the middle divider between what will later become storage and the milling area:

Using my handy dandy Kregg jig, I glued and pocket holed all joints:

Next was the dividing wall between the motor and my catch bin: