shoo

Well-Known Member

- Joined

- Aug 14, 2017

- Messages

- 93

- Reaction score

- 28

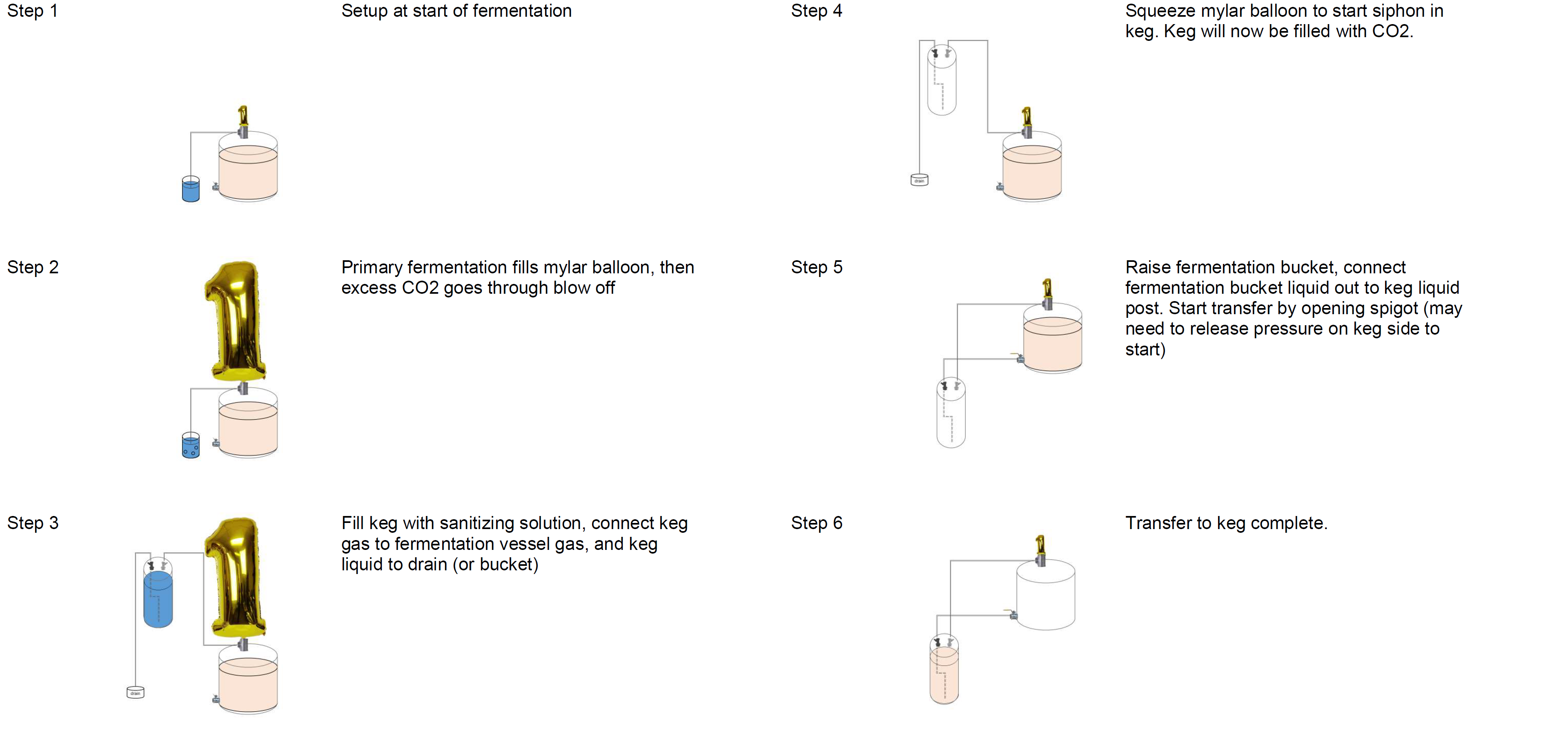

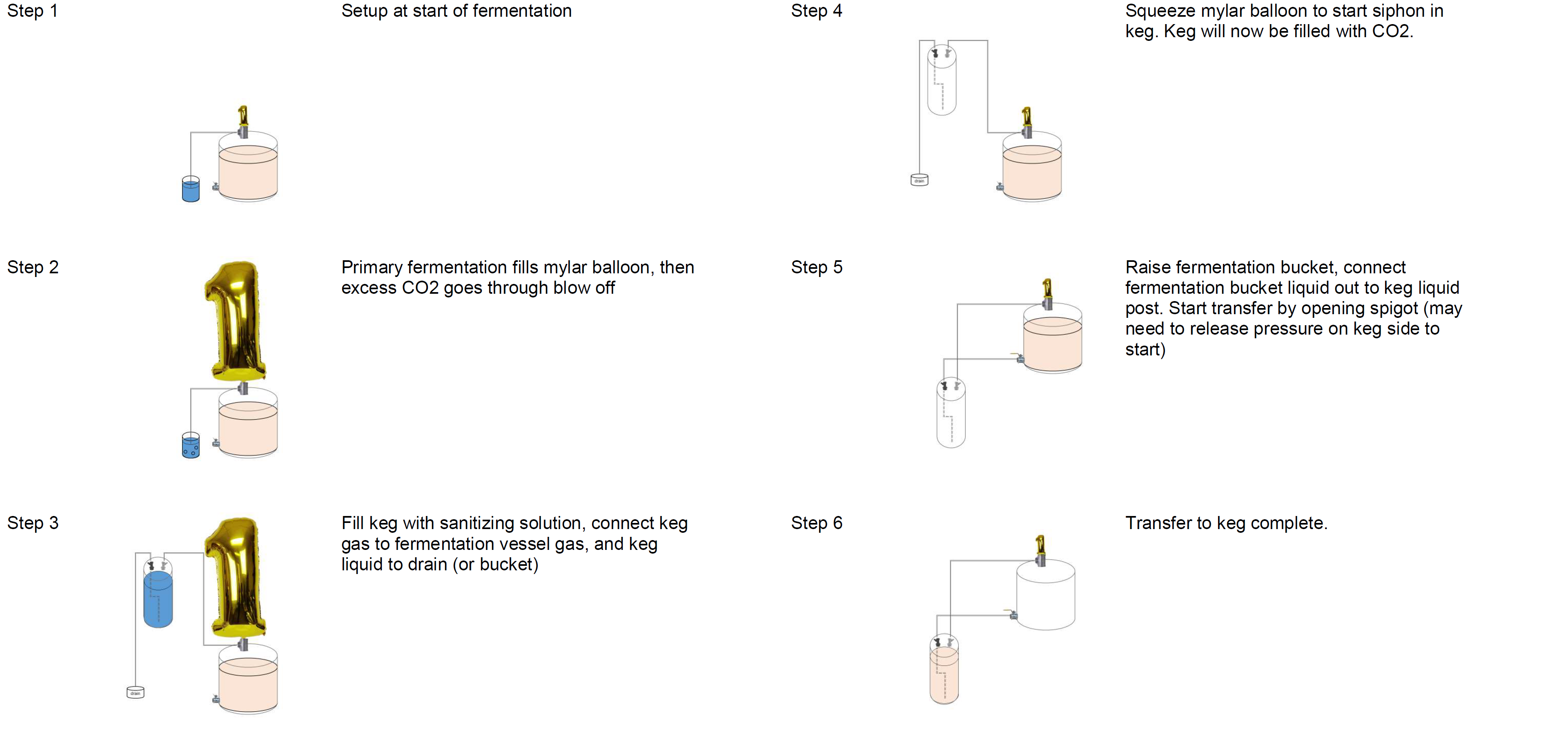

I have a very silly idea. I generally transfer from primary to keg/secondary through filling a keg with sanitizer, pushing it out using CO2 in my CO2 tank, and using a closed loop transfer from fermentor to keg. That seems like a waste of CO2, not to mention it's kindof a pain to take my tank out of the kegerator every time I want to do that. Got me thinking if there was a relative cheap/easy way to do this bypassing the tank altogether, using a balloon filled with CO2 from the primary.

Here's what I came up with. Haven't tried it yet, may give it a go on the next batch.

Thoughts? Also, where might I find a 30-40 liter mylar or similar balloon?

Here's what I came up with. Haven't tried it yet, may give it a go on the next batch.

Thoughts? Also, where might I find a 30-40 liter mylar or similar balloon?

Last edited: