Started my build today. My goal is a relatively simple, yet decent looking keezer with quality components. Picked up a lot of the parts over black Friday weekend from sales. I was going to go with a 7 cf freezer, but as I started putting kegs in I realized things would really be packed in. So I spent the extra coin on the bigger unit, and this freezer will comfortably hold 5 kegs on the floor, maybe 6, and I don't have to deal with having a huge collar to fit kegs on the hump.

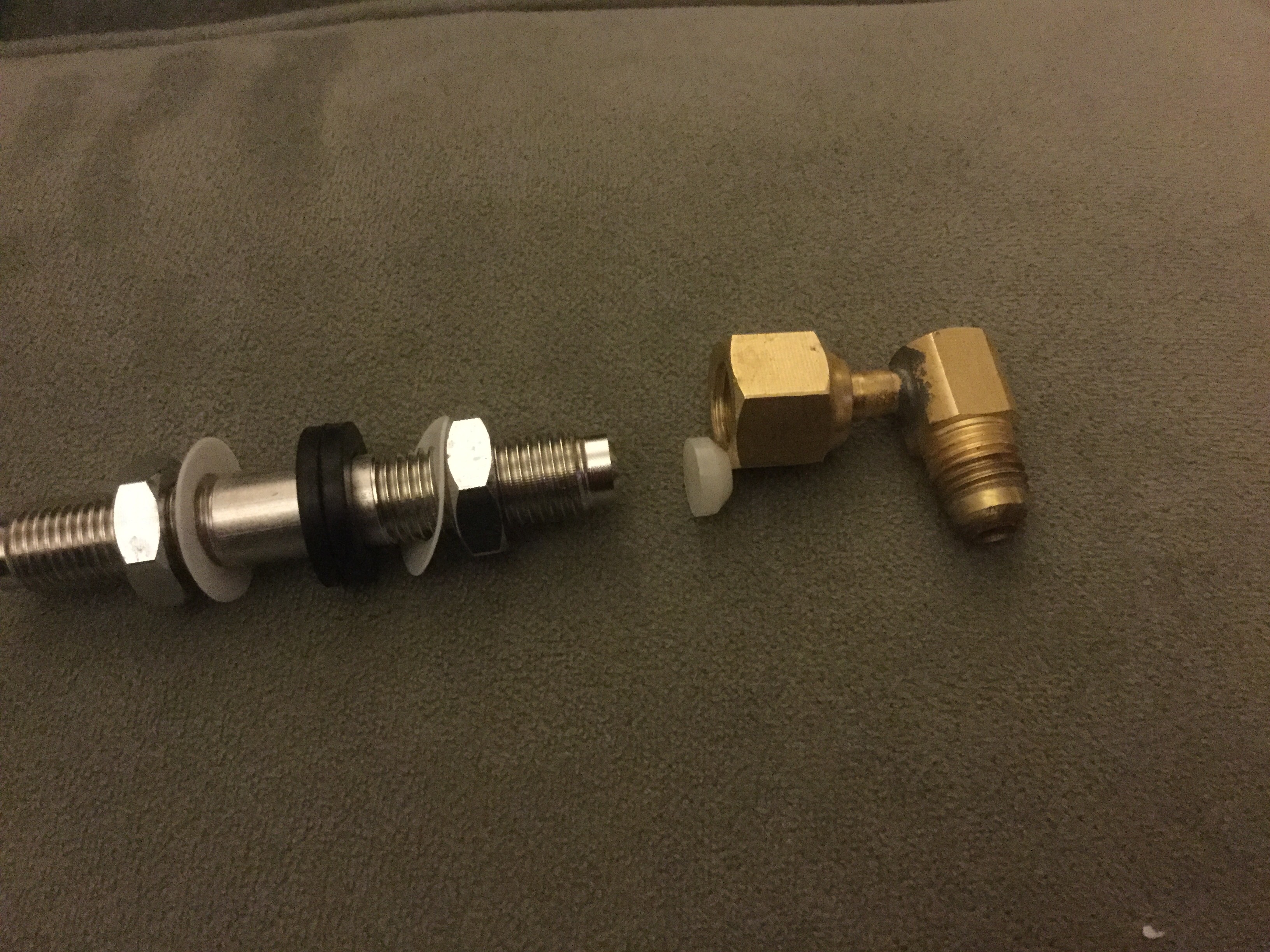

The keezer is going to have 4 taps. I'm using Perlick flow control faucets and all stainless where possible. Went with a 20 lb tank, which will be out side of the freezer, and a Taprite dual pressure regulator. One gas line will go to a 4 line distribution block for serving, and the other will be for carbing the keg that's "on deck." I picked up two bulkheads from CHI Company for getting the gas lines thru the collar. For liquid lines I'm using Ultra Barrier Antimicrobial & PVC Free tubing and Ultra Barrier PVC free 5/16" for gas. Almost all connections will be MFL.

Since I didn't have to deal with having anything sit on the hump, I decided to make a 6" collar, with 8" oak on the outside. Then to raise everything up a little bit I'm going to build a 6" base for the keezer to sit on.

Some pics from today. Tomorrow the base gets built.

Forgot to add, the quality time spent with my grandfather in his workshop.......priceless.

The keezer is going to have 4 taps. I'm using Perlick flow control faucets and all stainless where possible. Went with a 20 lb tank, which will be out side of the freezer, and a Taprite dual pressure regulator. One gas line will go to a 4 line distribution block for serving, and the other will be for carbing the keg that's "on deck." I picked up two bulkheads from CHI Company for getting the gas lines thru the collar. For liquid lines I'm using Ultra Barrier Antimicrobial & PVC Free tubing and Ultra Barrier PVC free 5/16" for gas. Almost all connections will be MFL.

Since I didn't have to deal with having anything sit on the hump, I decided to make a 6" collar, with 8" oak on the outside. Then to raise everything up a little bit I'm going to build a 6" base for the keezer to sit on.

Some pics from today. Tomorrow the base gets built.

Forgot to add, the quality time spent with my grandfather in his workshop.......priceless.