I did it Redneck Style, Deluxe, i.e. no duck tape. I placed a big zip tie around the neck of the BMB. Then I took another one and passed it underneath that one, across the mouth of the BMB, under the first zip tie on the opposite side, and back to the ratchety end. I then zipped the one around the neck good and tight and cut off the end. Stuck the lid on and pressed it home, and positioned both sides of the looped over the top one over the lid, to either side of the stopper hole, and zipped that one tight enough to hold the lid down, but still barely loose enough to work it out to the sides and remove the lid. If you accidentally zip it too tight you can reach inside and trip the little ratchet pawl with a scratch awl or something, and release it.

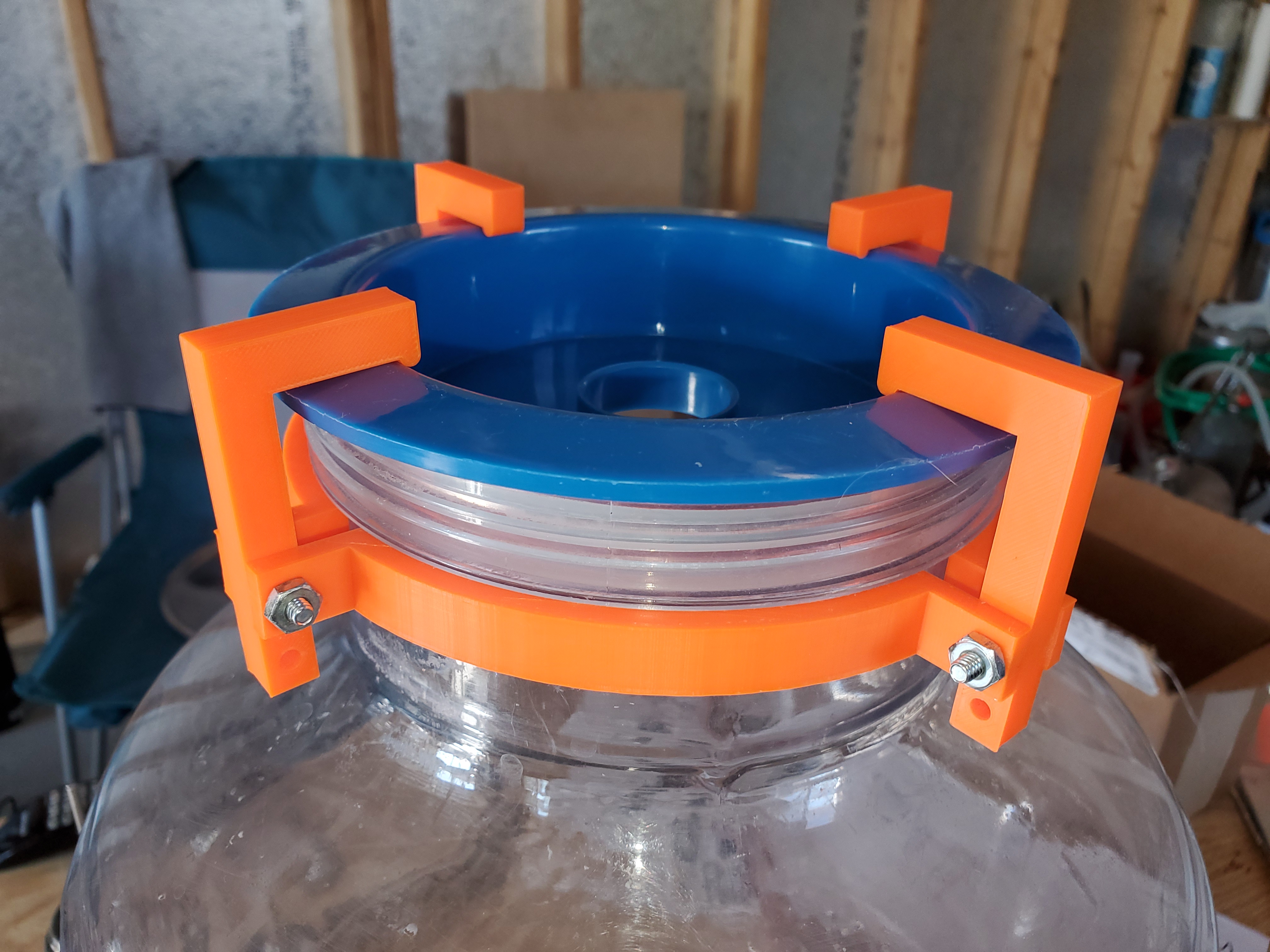

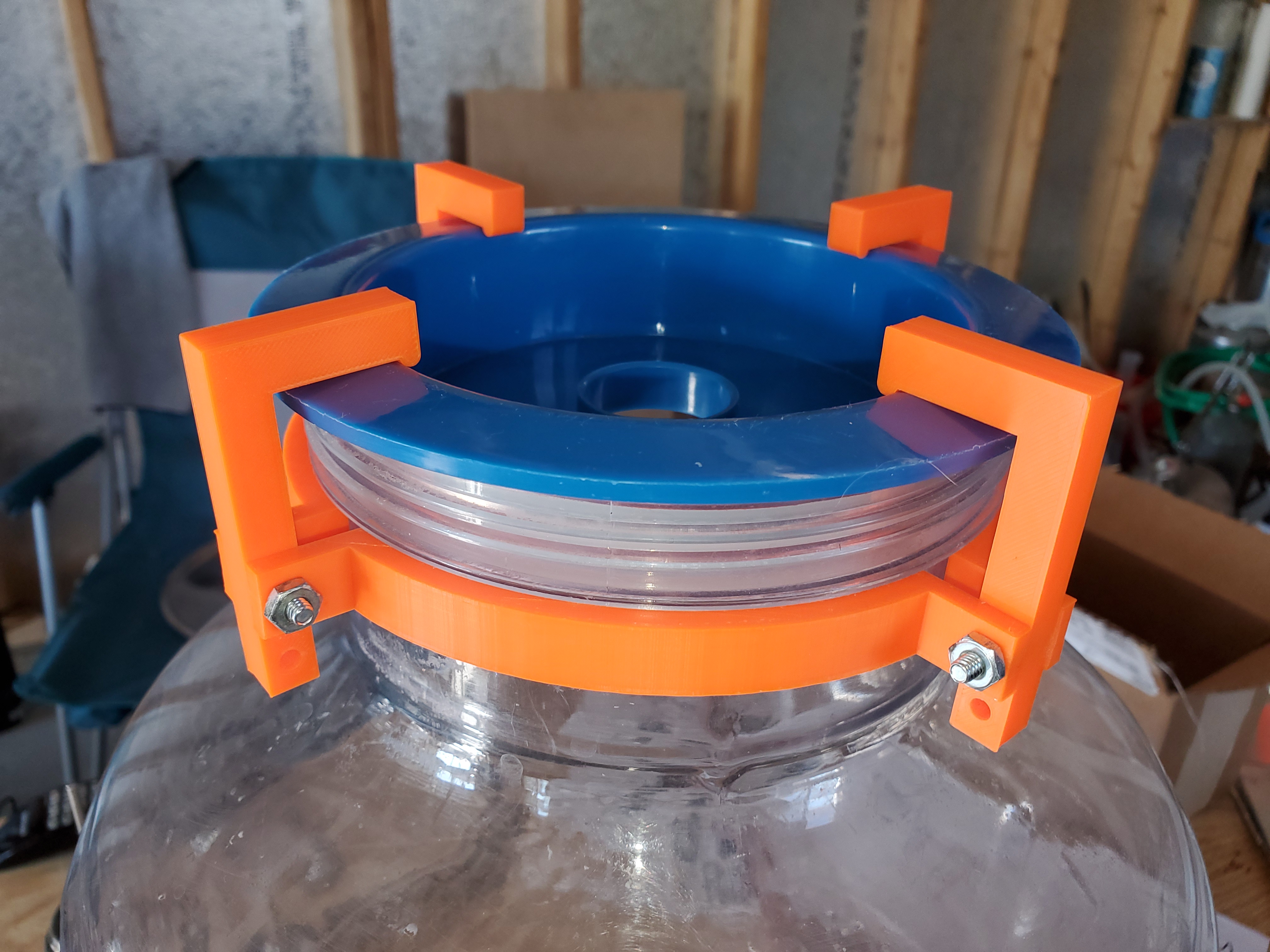

I do like the 3D printed one above, though. I might make myself one some day. Right now my printer is in a state of neglect and disrepair and I have other more pressing projects. But the zip ties are at least better than duck tape. Meanwhile it would be a pretty quick and simple thing to just make a neck band out of steel with a couple of nuts welded to the sides, and a hold-down bar across the top with a central hole for the airlock access and holes for bolts to run into the nuts on the neck band. Thumbscrews actually. I have also been thinking about a steel neck band with handles on it for moving the BMB around, and maybe a custom dolly for underneath.

Aluminum would be nice instead of steel but I don't have what I need for welding aluminum. Or stainless steel.

Another way to do just hold the lid on would be to pass a ratchet strap under the bottom and over the top and tighten it just enough to keep the lid secure without squashing the BMB down. You would have to be careful not to dislodge it while moving it around. Or just don't move it around.

I am sort of disappointed in the design, though, that it doesn't have any molded-in deadeyes that could be used for lashing the lid down or attaching handles. I guess they figured it would never have any pressure under it and they are well, almost always right on that account. There are so many things I like about it, I guess, that the flaws are more irritating than if it just plain sucked.

If you get one of those web belt contraptions for the BMB with the carry straps on it, you could lash over the lid from that, too.

poste haste.

poste haste.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)