So I've been really thinking about my electric brewery upgrade the past few days and I've hit the point where I need people with experience to weigh in.

I'm an experienced brewer with 100 batches of extract and 200+ batches of brew in a bag under my belt. Recently I've realized that I want a few features that propane BIAB struggles with: mash underletting, step mashing, and vorlaufing mostly.

I don't want to hear arguments for not needing any of those things please. I've been brewing for 10 years and I know what features I want at this point. Those are capabilities I want to have based on my experience and my brewing style.

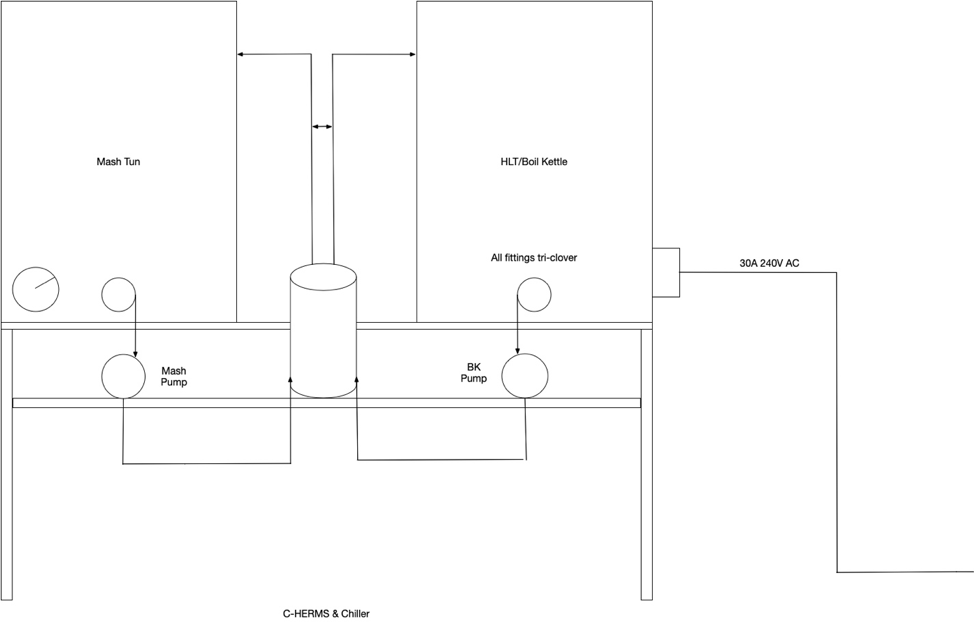

So I had my mind all made up that I could do a sweet 2 vessel BIAB system with a counterflow chiller acting as a HERMS.

But then I got thinking... What's the benefit there? I will still have to clean 2 vessels, and with a 3-vessel system I would have even simpler plumbing and I can have a dedicated HERMS coil.

So people with experience, I would love to get your feedback. Is there any real benefit to a 2 vessel system vs a 3 vessel other than cost?

My budget will be pretty high when it comes time to pull the trigger so I'm more of the mind to buy the system I want, not the system I can afford.

Edit: I just thought of the fact that I would need 2 heating elements instead of 1, and a more complex controller box for 3 vessels.

I'm an experienced brewer with 100 batches of extract and 200+ batches of brew in a bag under my belt. Recently I've realized that I want a few features that propane BIAB struggles with: mash underletting, step mashing, and vorlaufing mostly.

I don't want to hear arguments for not needing any of those things please. I've been brewing for 10 years and I know what features I want at this point. Those are capabilities I want to have based on my experience and my brewing style.

So I had my mind all made up that I could do a sweet 2 vessel BIAB system with a counterflow chiller acting as a HERMS.

But then I got thinking... What's the benefit there? I will still have to clean 2 vessels, and with a 3-vessel system I would have even simpler plumbing and I can have a dedicated HERMS coil.

So people with experience, I would love to get your feedback. Is there any real benefit to a 2 vessel system vs a 3 vessel other than cost?

My budget will be pretty high when it comes time to pull the trigger so I'm more of the mind to buy the system I want, not the system I can afford.

Edit: I just thought of the fact that I would need 2 heating elements instead of 1, and a more complex controller box for 3 vessels.

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)