You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2-vessel HERMS or 3 vessels?

- Thread starter TheMadKing

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

So just an update for everyone, I've been watching every video of 1, 2, and 3 vessel systems I can find, I sat down and wrote out my requirements and the things I could compromise on, and after very careful thought I've decided to go with a 3-vessel Spike-based system

I'm basically taking their turnkey HERMS system, making minor modifications to the temp probe placements, replacing their pumps with a chugger (already have) for water and a Blichmann riptide for wort, I sourced my own table, and I'm going to use an Auber Brew Buddy panel.

I intend to use a bag in the mash tun for ease of cleaning, and I may remove the false bottom for most brews and use only the bag since I've found out that they are a pain to clean. That should allow me to clean the entire system in place.

This setup allows me the greatest flexibility to use almost any brewing techniques that I want i.e. biab, kettle rims, herms, traditional, hybrid 2 vessel.

I just wanted to say thank you to everyone on this thread that posted replies, you guys gave me a great starting point/foundation to really get at the core of my decision.

This is an expensive decision at $4400... But I think it will be worth it in the long run, and I will never really need to buy any hotside equipment again.

Cheers! [emoji482]

I'm basically taking their turnkey HERMS system, making minor modifications to the temp probe placements, replacing their pumps with a chugger (already have) for water and a Blichmann riptide for wort, I sourced my own table, and I'm going to use an Auber Brew Buddy panel.

I intend to use a bag in the mash tun for ease of cleaning, and I may remove the false bottom for most brews and use only the bag since I've found out that they are a pain to clean. That should allow me to clean the entire system in place.

This setup allows me the greatest flexibility to use almost any brewing techniques that I want i.e. biab, kettle rims, herms, traditional, hybrid 2 vessel.

I just wanted to say thank you to everyone on this thread that posted replies, you guys gave me a great starting point/foundation to really get at the core of my decision.

This is an expensive decision at $4400... But I think it will be worth it in the long run, and I will never really need to buy any hotside equipment again.

Cheers! [emoji482]

Good luck - I am sure you will be happy with your choices! Would love to see pics of your gear after you get it set up.

Yes good luck to you! For what it's worth I have a three vessel e-herms and I absolutely love it. Once I dialed it in it's very consistent and repeatable, when you want to make the same recipe and have it come out the same as the last time you brewed it. I also make outstanding beer with it. It's a great tool in my hands so to speak. I think you can make great beer with any system you have dialed in and are proficient with though, and my rig is perfect for me. Again lots of luck and be sure to post up a pick or two when you get her going!

John

John

I have officially received wife approval for the plan!! I ordered my Auber Instruments Brew Buddy I panel kit this morning ($1140 including all TC temp probes, a wire kit, shipping and tax) and I'll put that together over the coming weeks, while I work myself up to dropping the big chunk of change on the spike gear. It'll be a slow process but I'm pumped to be going E-HERMS!

Ahks

Well-Known Member

Sounds like a great plan and a great system!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$33.95

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Bridgeview Beer and Wine Supply

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

Update, I ordered my Spike gear! 3 kettles, all the fittings, heating elements, HERMS coil... All I need now are a blichmann riptide, a stainless table, and a couple TC fittings!

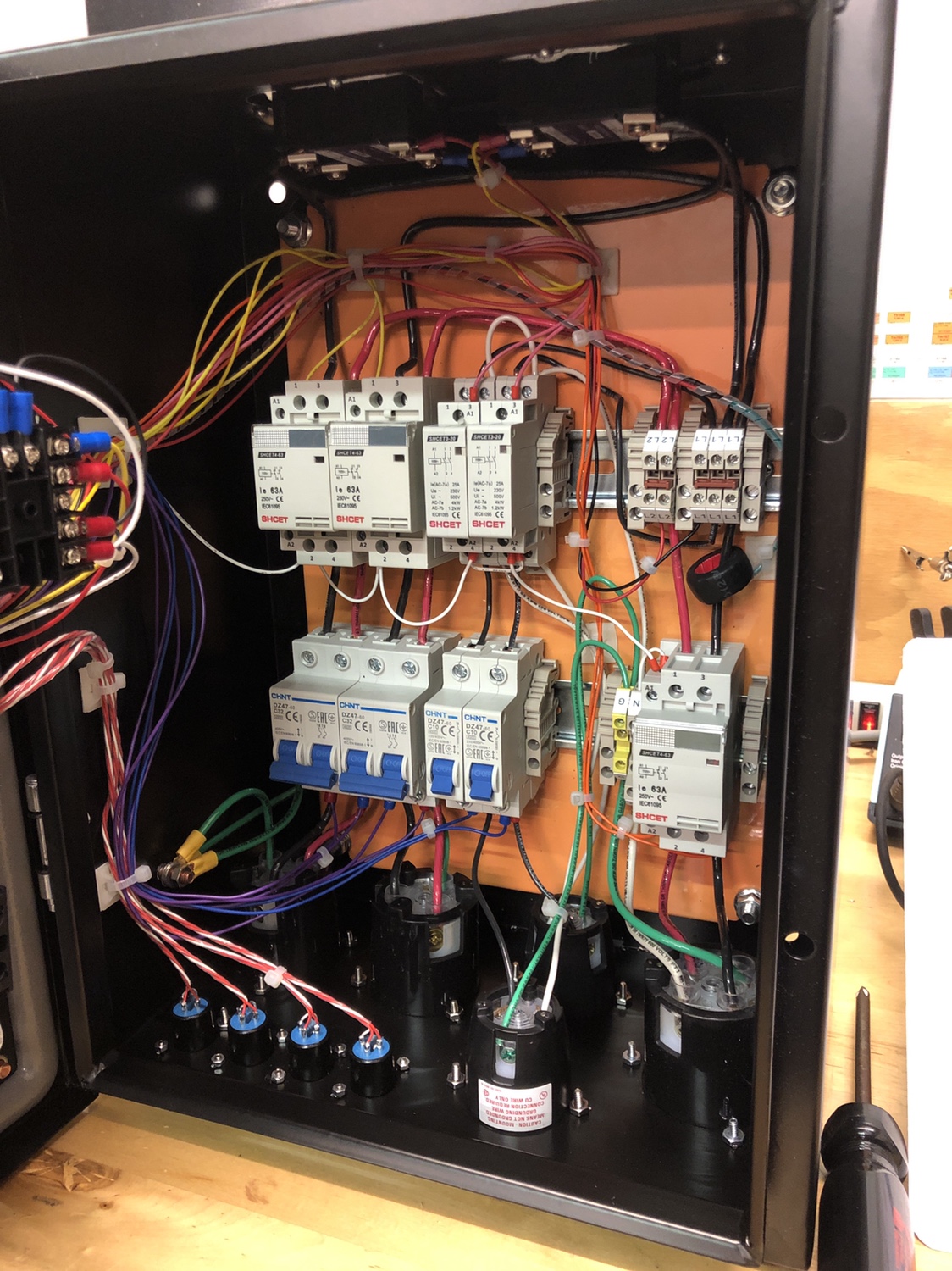

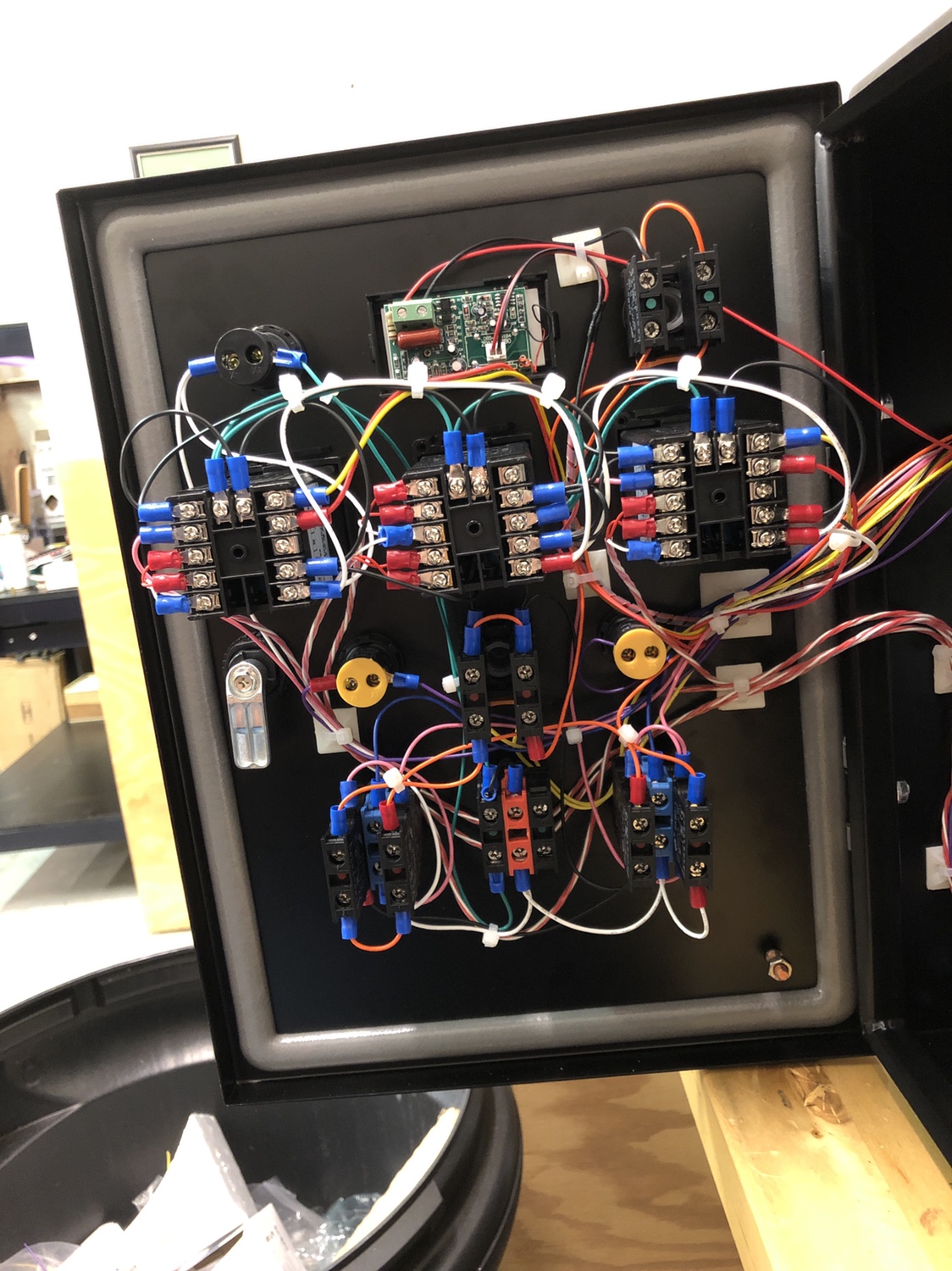

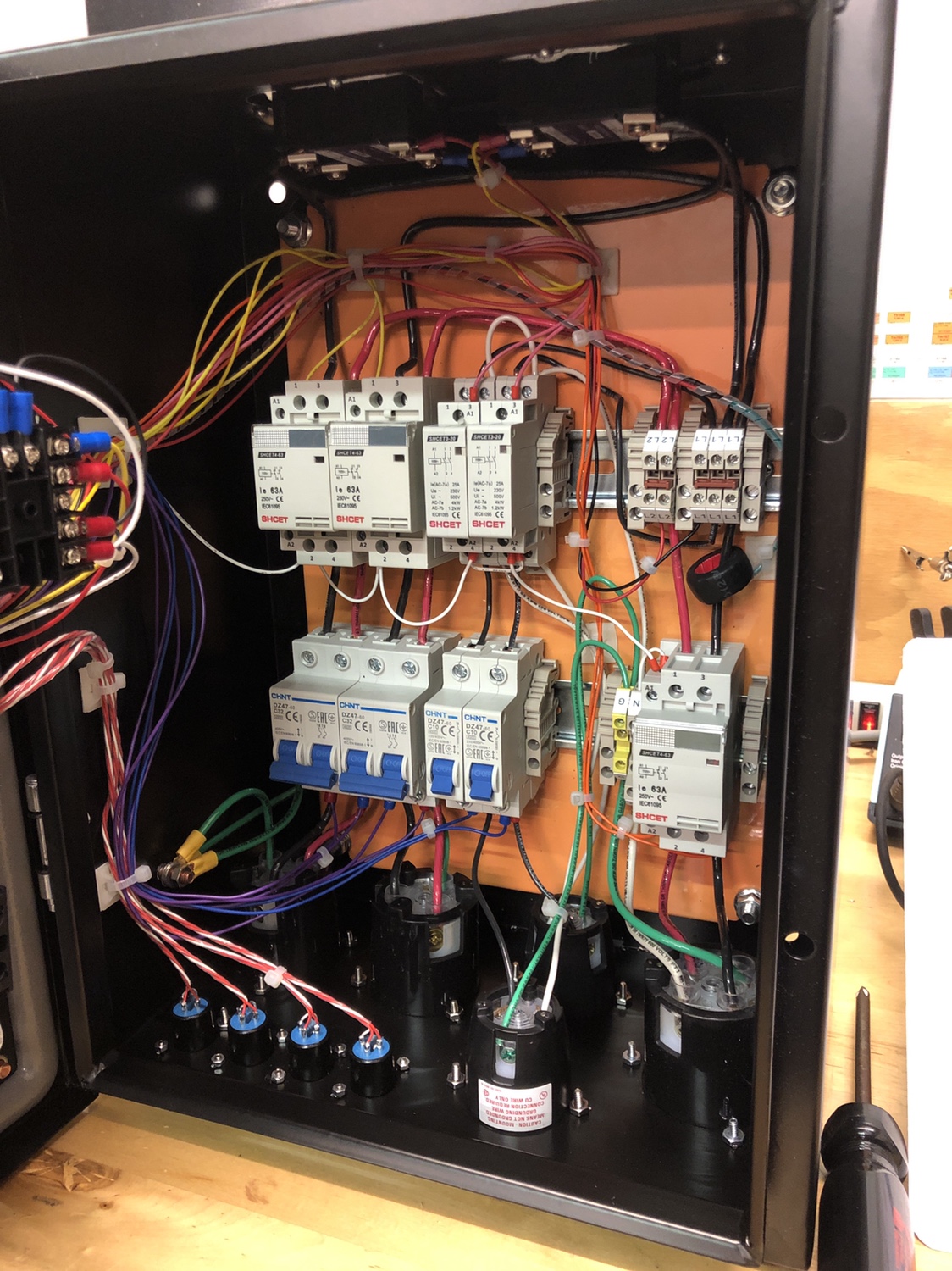

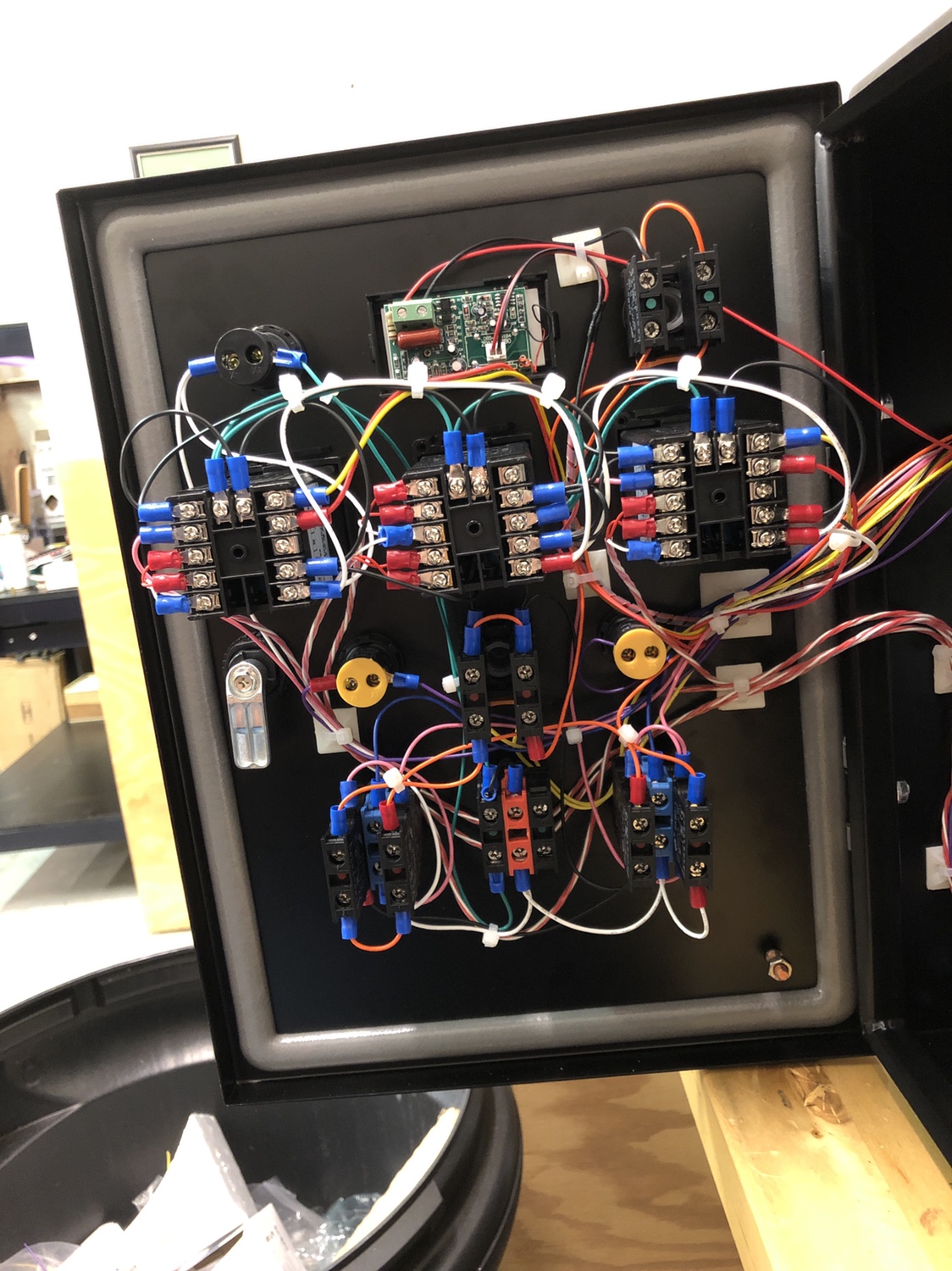

I'm about 75% done assembling my Auber panel and it's been surprisingly easy so far.

After that I'll need to put in a 50amp outlet in my garage and I'll be able to test this thing out!

I'll be learning to brew all over again.. Hopefully for the last time

I'm about 75% done assembling my Auber panel and it's been surprisingly easy so far.

After that I'll need to put in a 50amp outlet in my garage and I'll be able to test this thing out!

I'll be learning to brew all over again.. Hopefully for the last time

Last edited:

Looks like your on your way! I remember when I was building mine and it was like Christmas when all the packages started arriving at my door several times as week! Post some pics as you go of your progress.

John

John

Here's the progress to date on my panel. I just need to wire up the front panel and get my cables nice and clean and it'll be finished.

The panel is finished! Now to figure out how to get power to it... Started another thread for a sanity check

Great work! It is good you are going to get advice on powering it up. There are some experts here that will chime in.

John

John

augiedoggy

Well-Known Member

Easily avoidable with the right element and proper use.. I started with herms and went to rims and theres no comparision IMO..Yes, I want to be able to do acid rests which seem to cause nothing but problems with RIMS systems. There's just so many "I scorched my wort" threads about RIMS systems that it seems like an eventuality that I would rather avoid entirely.

I sure you will have good luck with your herms but if you ever happen to use a properly designed rims you'll likely want to upgrade immediately for the time savings alone.

Last edited:

augiedoggy

Well-Known Member

more than one way to skin a cat,I use a special UWLD RIMS so it may not be a fair comparison, but I did previously use a regular 1375W foldback without issue. THat said, I think you should always:

1. Have the tube vertically oriented.

2. Have the temp sensor right at the top.

3. Make sure the flow is at least 2 gals per minute.

I also use ULWD cartridge heaters but both my rims tubes are mounted horizonatally on the slightest angle so the air is pushed out and they drain correctly..

Also my home rims utilizes 1.5-1.8gpm MAX flow rate... As you know it works well and I average 91% efficiency at home this way.. if I had a rims element that was higher watt density I would not have such results im guessing.

at the brewpub we are still hovering around 85% but thats with 4-5gpm flowrate.

anyway sorry to go off topic here.. back to your build Mad King

more than one way to skin a cat,

I also use ULWD cartridge heaters but both my rims tubes are mounted horizonatally on the slightest angle so the air is pushed out and they drain correctly..

Also my home rims utilizes 1.5-1.8gpm MAX flow rate... As you know it works well and I average 91% efficiency at home this way.. if I had a rims element that was higher watt density I would not have such results im guessing.

at the brewpub we are still hovering around 85% but thats with 4-5gpm flowrate.

anyway sorry to go off topic here.. back to your build Mad King

Not off topic at all! I appreciate the input

I decided to go with the 3-vessel herms because it seems to offer the most options in terms of using different brewing techniques, but if I find that I just hate the effort and the long brew days then I may be looking to make a change.

That being said I don't think that will be the case. I truly enjoy my brew days and I always plan to use a full day anyway and I do everything at a relaxed pace. There's a lot of sitting around sipping a beer when I brew (now for example). So I don't think I'll mind adding a couple hours of time between sparging and cleaning the 3v system.

Easily avoidable with the right element and proper use.. I started with herms and went to rims and theres no comparision IMO..

I sure you will have good luck with your herms but if you ever happen to use a properly designed rims you'll likely want to upgrade immediately for the time savings alone.

I agree. HERMs works fine, but then again before jets we crossed the Atlantic in wooden ships...

I agree. HERMs works fine, but then again before jets we crossed the Atlantic in wooden ships...

It would take a lot of convincing to make me believe the difference is that stark...

I could see making the argument that's it's like flying first class vs coach, but I really don't see a difference in terms of benefit. They accomplish the same thing with close to the same amount of time and effort. To me that would just come down to personal preference

bigdawg86

Well-Known Member

- Joined

- May 1, 2017

- Messages

- 468

- Reaction score

- 197

I was trying to decide a similar thing... all electric with RIMS (since I already have a RIMS setup for BIAB) but then I realized that I would need a element to fire the HLT, have the RIMS circuit, and the boil kettle... While it could work needing the SSbrewtech 3V controller for a integrated RIMS system plus having to need TWO 240v circuits changed my mind. I decided 3 vessel HERMS and will be using SSBrewtechs 2V controller.

postalbunny

Well-Known Member

A little late... but i'll chime in. I originally had a 3 vessel brutus clone /w automated propane (hlt and mlt burners). Worked fine, but was tired of propane hassle (filling, keeping track of tanks, etc). It was very fast at getting items to temp... so when i scoped out an electric setup I made sure to go big so I wasn't giving up anything.

Next I converted the brutus to an electric eherms /w dual elements. Using spike kettles and a kal clone for panel. This setup worked fine, due to the dual elements my HLT water heating times were bonkers (15-30m depending on size). The thing that bothered me /w this setup was lag time for heating the MLT up. Doing step mashes takes longer, because you have to heat the HLT to a higher temp and wait for the MLT to catch up. Mash in might take 10-15 to stabilize. I had an extra plate heat so I plumbed it in on the HLT loop and would setup my doah in to be at "strike" temp (160ish degF) and then use ground water to knock the HLT down to mash temp (145-155ish depending on recipe). That was fine too... but mash "out" or step mashes take time as well. Heating to 160 or 168 took no time at all for HLT with dual elements but it took 15-20 for MLT to catch up. These are all really non-issues but they bothered me since I spent so much time designing/building this setup.

So i removed the herms coil and plumbed in a RIMs tube /w a cartridge heater (2000watt 240v). Since I had a dual element 50amp panel design i was able to squeeze another SSR in and wired one of the boil kettle's elements into the rims tube (5500 watt is fine for boiling 10-15g wort). This setup I like better, as i have more freedom and the temp control over the MLT is more responsive. It's more expensive than an eherms setup. I still have dual elements in my HLT, a single element in the boil kettle, and due to the 50amp panel i'm actually able to fire one of HLT elements, rims tube, and kettle at the same time. This makes back-to-back batches a breeze as well as cleaning (I can heat PBW with the RIMs tube cleaning the MLT while still boiling in the kettle)

The setup you just built is fine, and if you want to try RIMs in the future it's not a hard add-on. The 3 vessel setup is def the best IMO, having a separate HLT with hot water for various task comes in handy.

Next I converted the brutus to an electric eherms /w dual elements. Using spike kettles and a kal clone for panel. This setup worked fine, due to the dual elements my HLT water heating times were bonkers (15-30m depending on size). The thing that bothered me /w this setup was lag time for heating the MLT up. Doing step mashes takes longer, because you have to heat the HLT to a higher temp and wait for the MLT to catch up. Mash in might take 10-15 to stabilize. I had an extra plate heat so I plumbed it in on the HLT loop and would setup my doah in to be at "strike" temp (160ish degF) and then use ground water to knock the HLT down to mash temp (145-155ish depending on recipe). That was fine too... but mash "out" or step mashes take time as well. Heating to 160 or 168 took no time at all for HLT with dual elements but it took 15-20 for MLT to catch up. These are all really non-issues but they bothered me since I spent so much time designing/building this setup.

So i removed the herms coil and plumbed in a RIMs tube /w a cartridge heater (2000watt 240v). Since I had a dual element 50amp panel design i was able to squeeze another SSR in and wired one of the boil kettle's elements into the rims tube (5500 watt is fine for boiling 10-15g wort). This setup I like better, as i have more freedom and the temp control over the MLT is more responsive. It's more expensive than an eherms setup. I still have dual elements in my HLT, a single element in the boil kettle, and due to the 50amp panel i'm actually able to fire one of HLT elements, rims tube, and kettle at the same time. This makes back-to-back batches a breeze as well as cleaning (I can heat PBW with the RIMs tube cleaning the MLT while still boiling in the kettle)

The setup you just built is fine, and if you want to try RIMs in the future it's not a hard add-on. The 3 vessel setup is def the best IMO, having a separate HLT with hot water for various task comes in handy.

A little late... but i'll chime in. I originally had a 3 vessel brutus clone /w automated propane (hlt and mlt burners). Worked fine, but was tired of propane hassle (filling, keeping track of tanks, etc). It was very fast at getting items to temp... so when i scoped out an electric setup I made sure to go big so I wasn't giving up anything.

Next I converted the brutus to an electric eherms /w dual elements. Using spike kettles and a kal clone for panel. This setup worked fine, due to the dual elements my HLT water heating times were bonkers (15-30m depending on size). The thing that bothered me /w this setup was lag time for heating the MLT up. Doing step mashes takes longer, because you have to heat the HLT to a higher temp and wait for the MLT to catch up. Mash in might take 10-15 to stabilize. I had an extra plate heat so I plumbed it in on the HLT loop and would setup my doah in to be at "strike" temp (160ish degF) and then use ground water to knock the HLT down to mash temp (145-155ish depending on recipe). That was fine too... but mash "out" or step mashes take time as well. Heating to 160 or 168 took no time at all for HLT with dual elements but it took 15-20 for MLT to catch up. These are all really non-issues but they bothered me since I spent so much time designing/building this setup.

So i removed the herms coil and plumbed in a RIMs tube /w a cartridge heater (2000watt 240v). Since I had a dual element 50amp panel design i was able to squeeze another SSR in and wired one of the boil kettle's elements into the rims tube (5500 watt is fine for boiling 10-15g wort). This setup I like better, as i have more freedom and the temp control over the MLT is more responsive. It's more expensive than an eherms setup. I still have dual elements in my HLT, a single element in the boil kettle, and due to the 50amp panel i'm actually able to fire one of HLT elements, rims tube, and kettle at the same time. This makes back-to-back batches a breeze as well as cleaning (I can heat PBW with the RIMs tube cleaning the MLT while still boiling in the kettle)

The setup you just built is fine, and if you want to try RIMs in the future it's not a hard add-on. The 3 vessel setup is def the best IMO, having a separate HLT with hot water for various task comes in handy.

Thanks! I appreciate the input

The lag time between your HLT and MT seems odd to me, if you are recirculating the mash through a HERMS coil at high flow rates while you heat the HLT, I would think they would increase temp simultaneously with just a few degrees. I've seen several other threads that confirm that this is the norm.

Maybe your coil was too short or your flow rate was too low?

Either way a 15-20 minute rise time isn't bad and it's more gentle on the wort anyway.

postalbunny

Well-Known Member

I don't want to turn your thread into a RIMS vs HERMS debate, but i'll give you an example as to how the lag time is there vs RIMs. I'm not talking about the temp lag between the HLT and MLT; that's there and usually 1-2degF depending on your components. I'm talking about the difference between heating in a RIMs vs HERMs. The HERMs will always be slower. How much slower depends on your setup.

Lets say your HLT is at 152degF and that keeps your mash at 150degF. Then you go mash out at 168 so you set your HLT to 170 targeting a 168 in the MLT. When wort exits the coil in the HLT it will be at whatever temp the HLT is... but it takes 7-10 minutes to heat the 14gallons of HLT water from 152 to 170 with a 5500watt element. So while the HLT gets to 170 you will be heating the MLT recirc loop water to only whatever temp the HLT is... halfway into the ramp you'll have wort exiting the coil at 160, so your MLT can't be any warmer than 160. This is what I mean by laggy. With a RIMs you're wort exits the tube at 170 as soon as you hit "go". Your wort will be whatever temp you want as soon as you hit go, the grain/mlt still has to catch up. but it will catch up quicker because you're dumping 170deg wort into the top of the MLT not 152, 153, 154, etc... as the HERMS slowly heats the HLT up over 10 minutes.

You also do not have to heat up so much water to start brewing. HERMS guys like to keep their coil covered (not really 100% necessary) but that means in a 20g in the HLT. You need 14g of water plus the strike volume you put in the MLT (4-6g) ... about 20g. To heat the 20g from 70degF to 160degF it takes 50-60minutes. I only use 10g of that to make a 5g batch. So if i'm doing a RIMs then i heat only 10g of water and it takes half as long... HERMs guys have various ways to solve for this, they may heat just strike water up and transfer so they can dough-in while heating more water. Then recirc later... these various ways to combat the issue all have their side effects as well.

So the arguments are there, just pick your poison. Nothing wrong with the HERMS, but you'll see a few people that move on and change to RIMs. They usually do that because of the above two reasons. I also kept my HLT the same, and my coil is on standby.... if I have any issues with key components I can screw my herms coil in and do a herms batch no problem.

Lets say your HLT is at 152degF and that keeps your mash at 150degF. Then you go mash out at 168 so you set your HLT to 170 targeting a 168 in the MLT. When wort exits the coil in the HLT it will be at whatever temp the HLT is... but it takes 7-10 minutes to heat the 14gallons of HLT water from 152 to 170 with a 5500watt element. So while the HLT gets to 170 you will be heating the MLT recirc loop water to only whatever temp the HLT is... halfway into the ramp you'll have wort exiting the coil at 160, so your MLT can't be any warmer than 160. This is what I mean by laggy. With a RIMs you're wort exits the tube at 170 as soon as you hit "go". Your wort will be whatever temp you want as soon as you hit go, the grain/mlt still has to catch up. but it will catch up quicker because you're dumping 170deg wort into the top of the MLT not 152, 153, 154, etc... as the HERMS slowly heats the HLT up over 10 minutes.

You also do not have to heat up so much water to start brewing. HERMS guys like to keep their coil covered (not really 100% necessary) but that means in a 20g in the HLT. You need 14g of water plus the strike volume you put in the MLT (4-6g) ... about 20g. To heat the 20g from 70degF to 160degF it takes 50-60minutes. I only use 10g of that to make a 5g batch. So if i'm doing a RIMs then i heat only 10g of water and it takes half as long... HERMs guys have various ways to solve for this, they may heat just strike water up and transfer so they can dough-in while heating more water. Then recirc later... these various ways to combat the issue all have their side effects as well.

So the arguments are there, just pick your poison. Nothing wrong with the HERMS, but you'll see a few people that move on and change to RIMs. They usually do that because of the above two reasons. I also kept my HLT the same, and my coil is on standby.... if I have any issues with key components I can screw my herms coil in and do a herms batch no problem.

I don't want to turn your thread into a RIMS vs HERMS debate, but i'll give you an example as to how the lag time is there vs RIMs. I'm not talking about the temp lag between the HLT and MLT; that's there and usually 1-2degF depending on your components. I'm talking about the difference between heating in a RIMs vs HERMs. The HERMs will always be slower. How much slower depends on your setup.

Lets say your HLT is at 152degF and that keeps your mash at 150degF. Then you go mash out at 168 so you set your HLT to 170 targeting a 168 in the MLT. When wort exits the coil in the HLT it will be at whatever temp the HLT is... but it takes 7-10 minutes to heat the 14gallons of HLT water from 152 to 170 with a 5500watt element. So while the HLT gets to 170 you will be heating the MLT recirc loop water to only whatever temp the HLT is... halfway into the ramp you'll have wort exiting the coil at 160, so your MLT can't be any warmer than 160. This is what I mean by laggy. With a RIMs you're wort exits the tube at 170 as soon as you hit "go". Your wort will be whatever temp you want as soon as you hit go, the grain/mlt still has to catch up. but it will catch up quicker because you're dumping 170deg wort into the top of the MLT not 152, 153, 154, etc... as the HERMS slowly heats the HLT up over 10 minutes.

You also do not have to heat up so much water to start brewing. HERMS guys like to keep their coil covered (not really 100% necessary) but that means in a 20g in the HLT. You need 14g of water plus the strike volume you put in the MLT (4-6g) ... about 20g. To heat the 20g from 70degF to 160degF it takes 50-60minutes. I only use 10g of that to make a 5g batch. So if i'm doing a RIMs then i heat only 10g of water and it takes half as long... HERMs guys have various ways to solve for this, they may heat just strike water up and transfer so they can dough-in while heating more water. Then recirc later... these various ways to combat the issue all have their side effects as well.

So the arguments are there, just pick your poison. Nothing wrong with the HERMS, but you'll see a few people that move on and change to RIMs. They usually do that because of the above two reasons. I also kept my HLT the same, and my coil is on standby.... if I have any issues with key components I can screw my herms coil in and do a herms batch no problem.

No I like learning about new ways to do things. I'm already set on HERMS for several reasons. There is actually a good bit of literature that shows that slower/more gentle heating has minor flavor benefits for your finished beer. I'm also not big on saving total time. I genuinely enjoy my brew day as long as it's a smooth process and I never feel frantic or rushed. So once I learn any system I'll enjoy it no matter the method.

that's a good explanation though, thanks!

Why wouldn't you just heat your HLT water to 190 or so while your mash is resting at a rest temp and then as soon as you turn on the pump you are spitting out wort at a higher temp until they equilibrate at some lower temperature and then rise to the next rest temp? Seems like a good way to jump start it.

postalbunny

Well-Known Member

So that's one thought most have immediately, heat the HLT to 200 and then only turn the pump on to catch the MLT "up". The issue with this solution is that wort leaving the HLT coil matches the temp of the HLT, so it actually heats up to 200. Any time the enzymes go over 165-170 they start to denature (they will no longer convert). So you'll effectively "mash out" if you do this.

The best solution I've seen is to heat the HLT up to 160, transfer your sparge water and "heat" the mash tun up, then drop your HLT to 152 or whatever your mash temp is. Pop the lid on your HLT, top the water up with 70deg ground water and it'll help lower the HLT down. The draw back to "topping up" with water is if you are managing your water profiles. You'll have to know how much/what salts to add. If you're ground water is good to go, then you'll just have to kill chlorine/chloramine with a partial camden. I treat my water for the style, so this was a nogo for me.

The other solution I went with was to pipe my HLT recirc through a spare plat chiller I had, that way I could knock it back down fast. You still have lag heating up though, 5-10 extra minutes here/there never killed anyone. But my prev brew rig was propane direct fire RIMs and I rather liked know much faster it was.

That said, it just takes longer to ramp... there are a ton of people who enjoy brewing with their HERMs, and it's quite viable. I'm sure you won't be disappointing. Like I said earlier, just getting the 3 vessels is a huge win in itself. Since you already have the BIAB setup, i'd say you may not want a false bottom in the MLT. Using that BIAB for the mash will probably make cleanup easier.

The best solution I've seen is to heat the HLT up to 160, transfer your sparge water and "heat" the mash tun up, then drop your HLT to 152 or whatever your mash temp is. Pop the lid on your HLT, top the water up with 70deg ground water and it'll help lower the HLT down. The draw back to "topping up" with water is if you are managing your water profiles. You'll have to know how much/what salts to add. If you're ground water is good to go, then you'll just have to kill chlorine/chloramine with a partial camden. I treat my water for the style, so this was a nogo for me.

The other solution I went with was to pipe my HLT recirc through a spare plat chiller I had, that way I could knock it back down fast. You still have lag heating up though, 5-10 extra minutes here/there never killed anyone. But my prev brew rig was propane direct fire RIMs and I rather liked know much faster it was.

That said, it just takes longer to ramp... there are a ton of people who enjoy brewing with their HERMs, and it's quite viable. I'm sure you won't be disappointing. Like I said earlier, just getting the 3 vessels is a huge win in itself. Since you already have the BIAB setup, i'd say you may not want a false bottom in the MLT. Using that BIAB for the mash will probably make cleanup easier.

So that's one thought most have immediately, heat the HLT to 200 and then only turn the pump on to catch the MLT "up". The issue with this solution is that wort leaving the HLT coil matches the temp of the HLT, so it actually heats up to 200. Any time the enzymes go over 165-170 they start to denature (they will no longer convert). So you'll effectively "mash out" if you do this.

The best solution I've seen is to heat the HLT up to 160, transfer your sparge water and "heat" the mash tun up, then drop your HLT to 152 or whatever your mash temp is. Pop the lid on your HLT, top the water up with 70deg ground water and it'll help lower the HLT down. The draw back to "topping up" with water is if you are managing your water profiles. You'll have to know how much/what salts to add. If you're ground water is good to go, then you'll just have to kill chlorine/chloramine with a partial camden. I treat my water for the style, so this was a nogo for me.

The other solution I went with was to pipe my HLT recirc through a spare plat chiller I had, that way I could knock it back down fast. You still have lag heating up though, 5-10 extra minutes here/there never killed anyone. But my prev brew rig was propane direct fire RIMs and I rather liked know much faster it was.

That said, it just takes longer to ramp... there are a ton of people who enjoy brewing with their HERMs, and it's quite viable. I'm sure you won't be disappointing. Like I said earlier, just getting the 3 vessels is a huge win in itself. Since you already have the BIAB setup, i'd say you may not want a false bottom in the MLT. Using that BIAB for the mash will probably make cleanup easier.

I don't understand how it would denature ALL of the enzymes in the mash before the temp drops back below 160 - it surely can't be much different from doing a decoction mash is it? Or is that something you've experience personally?

Blazinlow86

Well-Known Member

- Joined

- Oct 19, 2016

- Messages

- 1,687

- Reaction score

- 743

I've done it 2 ways on my Herms setup. One way is filling the hlt fully and filling the MLT to the desired level, setting the hlt to my desired mash temp then waiting to dough in until the MLT is at the desired temp using recirculation. The downside to this method was it requires a very fluid grist to allow the liquid to turn over fast enough to quickly overcome the loss of temp from initially mashing in. It would take about 5 mins to get back to desired temps. Some forum members suggested that doing that way could hurt efficiency so I've tried it another way the last few times. I milled tighter at .035 this time and set the hlt temp higher than the desired mash temp to compensate for the initial drop at dough in. Once doughed in the temp was perfect however as mentioned above the hlt temp was appx 5-10deg to hot. Rather than adding cold water messing with the salt/ph of the sparge water I just waited 15 mins for the hlt to drop to the correct temps than recirculed as normal. Long story short my efficiency didn't improve at 88% however I think I liked the second way better as there's no temp drop initially. Hopefully that makes sense. Cheers

After rereading what I've posted to clarify I never preheat mash water and then transfer it to the MLT. I always heat the MLT water using the Herms coil.

After rereading what I've posted to clarify I never preheat mash water and then transfer it to the MLT. I always heat the MLT water using the Herms coil.

Last edited:

postalbunny

Well-Known Member

With a decoction you'll be heating a small portion up, and likely denaturing those enzymes unless you control how much you heat. A lot of peeps just basically boil the addition.

For setting your HLT to 200 you'll be cycling the full volume of mash/mlt wort ... as each part leaves the HLT it'll be denatured. So by cycling your pump only when you need to heat your MLT up a bit you'll be denaturing mash little bit by little bit.

If you want to give toggling the pump a try, i'd suggest just using 160 or 165 temp... but you will also need to know that you'll be modifying the profile of the beer somewhat. The wort that stays in the coil in-between toggling the pump on will be sitting at 165 for a long period of time. I also didn't want to try and wire up the PID to control the

Most people with herms are not doing this style, because of the draw backs. Doing a full recirc has other benefits too such as clarity in wort. Get a few under your belt and then

For setting your HLT to 200 you'll be cycling the full volume of mash/mlt wort ... as each part leaves the HLT it'll be denatured. So by cycling your pump only when you need to heat your MLT up a bit you'll be denaturing mash little bit by little bit.

If you want to give toggling the pump a try, i'd suggest just using 160 or 165 temp... but you will also need to know that you'll be modifying the profile of the beer somewhat. The wort that stays in the coil in-between toggling the pump on will be sitting at 165 for a long period of time. I also didn't want to try and wire up the PID to control the

Most people with herms are not doing this style, because of the draw backs. Doing a full recirc has other benefits too such as clarity in wort. Get a few under your belt and then

With a decoction you'll be heating a small portion up, and likely denaturing those enzymes unless you control how much you heat. A lot of peeps just basically boil the addition.

For setting your HLT to 200 you'll be cycling the full volume of mash/mlt wort ... as each part leaves the HLT it'll be denatured. So by cycling your pump only when you need to heat your MLT up a bit you'll be denaturing mash little bit by little bit.

If you want to give toggling the pump a try, i'd suggest just using 160 or 165 temp... but you will also need to know that you'll be modifying the profile of the beer somewhat. The wort that stays in the coil in-between toggling the pump on will be sitting at 165 for a long period of time. I also didn't want to try and wire up the PID to control the

Most people with herms are not doing this style, because of the draw backs. Doing a full recirc has other benefits too such as clarity in wort. Get a few under your belt and then

A decoction by definition is boiled (usually 20+ minutes of boiling) and the volume is typically 1/3rd of the mash at a time - so it's a very significant amount of denaturing and this still leaves plenty of enzymes to fully convert.

I'm not planning to try that initially, but I may give it a shot down the road just out of curiosity. A simple iodine test will tell me whether or not I've denatured my entire mash if there's still unconverted starch after 60 minutes.

You also have to keep in mind that the MT will remove heat from the HLT rapidly and I would think that the HLT water would drop from 200 back below 160 within 2-3 minutes if my plate chiller is any indication. Which I still think would leave plenty of enzymes available. - It'll be a curiosity brew

Blazinlow86

Well-Known Member

- Joined

- Oct 19, 2016

- Messages

- 1,687

- Reaction score

- 743

Just fwiw it did take about 15 mins to drop my 20gal hlt 5-10 degree with the lid off, constant stirring and not circulating the mash. It would definitely drop faster if recirculating but I imagine it would also increase you mash temp considerably.A decoction by definition is boiled (usually 20+ minutes of boiling) and the volume is typically 1/3rd of the mash at a time - so it's a very significant amount of denaturing and this still leaves plenty of enzymes to fully convert.

I'm not planning to try that initially, but I may give it a shot down the road just out of curiosity. A simple iodine test will tell me whether or not I've denatured my entire mash if there's still unconverted starch after 60 minutes.

You also have to keep in mind that the MT will remove heat from the HLT rapidly and I would think that the HLT water would drop from 200 back below 160 within 2-3 minutes if my plate chiller is any indication. Which I still think would leave plenty of enzymes available. - It'll be a curiosity brew

I personally feel that HERMs makes little sense other the fact that it saves you a high-voltage circuit. Heating liquid to heat liquid just doesn't jive to me. If you want to heat liquid... heat liquid! With the right RIMs design and supporting controls, any goals are easily achieved. Just saying... its my opinion that HERMs should be in our rear-view as brewers.

Blazinlow86

Well-Known Member

- Joined

- Oct 19, 2016

- Messages

- 1,687

- Reaction score

- 743

Guess it just depends on your process at the end of the day. For my setup literally all I would gain going with a rims set-up is more cost and equipment and for that reason i look at it as a downgrade. CheersI personally feel that HERMs makes little sense other the fact that it saves you a high-voltage circuit. Heating liquid to heat liquid just doesn't jive to me. If you want to heat liquid... heat liquid! With the right RIMs design and supporting controls, any goals are easily achieved. Just saying... its my opinion that HERMs should be in our rear-view as brewers.

More im thinking about it are the people doing a traditional mash setup with a rims just omitting the hlt all together? Im guessing you could just omit the element in the hlt and heat the mash and sparge water with the rims if using a 3v with the hlt just holding cold sparge water? Cheers

Last edited:

I personally feel that HERMs makes little sense other the fact that it saves you a high-voltage circuit. Heating liquid to heat liquid just doesn't jive to me. If you want to heat liquid... heat liquid! With the right RIMs design and supporting controls, any goals are easily achieved. Just saying... its my opinion that HERMs should be in our rear-view as brewers.

If you look at it from a pure energy efficiency standpoint I agree with you. But the point of making beer isn't to do it with as few Jules/gallon as possible.

I think that at the end of the day they are two different methods for accomplishing the same result. One is not the natural successor to the other.

Similar threads

- Replies

- 14

- Views

- 822