bwiens

Well-Known Member

Last year I started my build of a weldless brew stand. A number of batches and changes later it is very usable, but not finished. It does work very well and lends itself to design and process changes due to the construction type. The erector set model is flexible, strong and a cool conversation piece.

The Kettle and HLT have burners and are on the hot side of the stand. I added a divider to help keep the heat off of the cool side shelf. This was an afterthought, but the construction type easily allows for it.

I have water plumbed into the stand. I have a carbon filter mounted with the ability to bypass it once the brew water has been filtered. There is a hose bib on the back of the stand and a camlock on the front.

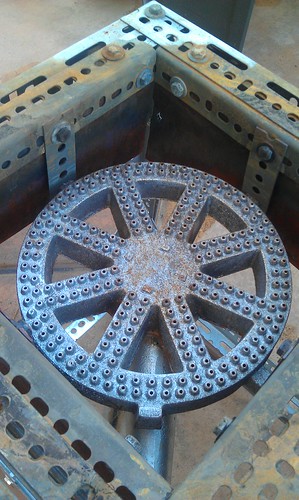

I use two Hurricane burners with natural gas valves. I have a union on the stand that connects to the gas hose that I connect to the stub in my backyard. These burners are great and are plenty hot. I dont think I am getting their full potential out of them due to my stub location being as far from the meter as possible, but it is enough. I added a windscreen to the kettle burner, but havent done the HLT burner yet. The windscreen is just some sheet metal I picked up at Home Depot/Lowes, cut to length and a couple holes drilled into them and bolted in place. Works well.

I am using two Little Giant pumps for moving liquids around and have camlocks and silicon hoses throughout. I went with the street elbows on all of the hoses and just threaded the hose onto the elbow and added a zip tie for a little security. I do have one hose that I added hose clamps to and use it for the input to the CFC due to the pressure increase due to the flow restriction through it.

(continued)