You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bottling Tips for the Homebrewer

- Thread starter Revvy

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

dragon99

Well-Known Member

I love the idea of using the bottling wand on my bucket! I didn't care for the wand coming off an autosiphon, but I also don't like having to twist the spigot for every bottle (I often get distracted and cut it off too late).

Thanks for the idea!

Thanks for the idea!

Another great day bottling thanks to Revvy!

cyberbackpacker

Well-Known Member

Bottled another 2.5g batch last night... actual bottling took me 6 minutes! Sweet!

Reinheitsgebot

Well-Known Member

Just thought I'd post this:

Revvy thanks so much for the guide. I have set up my stuff and I will bottle 2 bayches with it next Saturday.

For my last batch, however, I did not yet have a bottling bucket, so I used this as a quick fix:

I ran my autosiphon out of my primary with the primed beer in it. Attached to the siphon was a length of hose and the bottling wand. Here is my trick: I pushed the wand through the grommet of my primary lid, set the bucket on top of the lid, so that the lid hung over the edge of my countertop (over the dishwasher). Even though I did not have the spigot, it basically worked the same as your setup, and might be a (temporary) solution for those without a bottling bucket.

I managed to get all the beer out, maybe missing 2 or 3 ounces.

Thanks again for all your help, Revvy ( and all the other great posters). Thanks for giving me/us so much help in getting started. I am now 3 batches into it and constantly working on improving beer and gear.

Thanks!

Revvy thanks so much for the guide. I have set up my stuff and I will bottle 2 bayches with it next Saturday.

For my last batch, however, I did not yet have a bottling bucket, so I used this as a quick fix:

I ran my autosiphon out of my primary with the primed beer in it. Attached to the siphon was a length of hose and the bottling wand. Here is my trick: I pushed the wand through the grommet of my primary lid, set the bucket on top of the lid, so that the lid hung over the edge of my countertop (over the dishwasher). Even though I did not have the spigot, it basically worked the same as your setup, and might be a (temporary) solution for those without a bottling bucket.

I managed to get all the beer out, maybe missing 2 or 3 ounces.

Thanks again for all your help, Revvy ( and all the other great posters). Thanks for giving me/us so much help in getting started. I am now 3 batches into it and constantly working on improving beer and gear.

Thanks!

Just thought I'd post this:

Revvy thanks so much for the guide. I have set up my stuff and I will bottle 2 bayches with it next Saturday.

For my last batch, however, I did not yet have a bottling bucket, so I used this as a quick fix:

I ran my autosiphon out of my primary with the primed beer in it. Attached to the siphon was a length of hose and the bottling wand. Here is my trick: I pushed the wand through the grommet of my primary lid, set the bucket on top of the lid, so that the lid hung over the edge of my countertop (over the dishwasher). Even though I did not have the spigot, it basically worked the same as your setup, and might be a (temporary) solution for those without a bottling bucket.

I managed to get all the beer out, maybe missing 2 or 3 ounces.

Thanks again for all your help, Revvy ( and all the other great posters). Thanks for giving me/us so much help in getting started. I am now 3 batches into it and constantly working on improving beer and gear.

Thanks!

If you get a chance snap a pic of your rig!!!

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

jesutton3

Well-Known Member

Just a quick question on the bottling. After you have filled the bottle to the correct level. Approximatly 1" from the top. Do you have to worry about the oxygen in the top part of the bottle? I have no CO2 to purge with. Sunday will be the day I bottle my first batch.

Just a quick question on the bottling. After you have filled the bottle to the correct level. Approximatly 1" from the top. Do you have to worry about the oxygen in the top part of the bottle? I have no CO2 to purge with. Sunday will be the day I bottle my first batch.

By filling with a wand from the bottom to the top, and then letting the caps sit loosely on the bottle for a few minutes you are in effect purging the O2 out of the bottle....Since you added your sugar solution and beer to the bucket, some "carbonation" is already happening, so there is co2 already present, so as the beer is rising up from the bottom, the CO2 which is heavier than air, is pushing the O2 out of the bottle. Then by leaving the cap loose for a bit, as more co2 is produced, it further voids out the o2. I have actually had a couple caps fly off the top of the bottle because of that. If that happens I just drop that cap back in the sanitizer and grab another one.

jesutton3

Well-Known Member

When you say a few minutes are we talking 5 or hours?

When you say a few minutes are we talking 5 or hours?

Minutes....Here's what I do from the original post..

Since I'm a lefty I work right to left on my table....I put my two cases of sanitized bottles on the right hand side of the table (on the chair next to me,) I put the vinator on the table to the right of the bucket filled with my bottles caps sanitizing away. Then when I fill the bottle I place a cap loosely on it, and move it to the left side of the table...with the bottling bucket in the middle of the table there's room for a case worth of filled bottles on the table on the left side.

When I hit 24 bottles, I stand up, move the empty case to a chair on the left side of the table, then I pick up my capper and cap the first case of bottles, putting them in the case on the chair nearby...Then I grab a beer from the fridge, and sit back down and do the next case of beer....

Probably 5-10 minutes from the time I fill the first bottle in the case til the 24th...

womencantsail

Well-Known Member

I will be using a bucket with a "spigot" and the dishwasher for the bottling of my first batch (such as the setup shown in the OP). But I had a question regarding racking from the fermenter to my bottling bucket...

I have read many a passage in books and on the internet warning not to shake/slosh/stir the beer around so as to not oxidize it. My concern is that I will be bottling in the kitchen, but will have to move my carboy to get it there (it will be fermenting in another room, obviously). Is this not a problem or do I just need to make sure I take care to not disturb it too much?

I have read many a passage in books and on the internet warning not to shake/slosh/stir the beer around so as to not oxidize it. My concern is that I will be bottling in the kitchen, but will have to move my carboy to get it there (it will be fermenting in another room, obviously). Is this not a problem or do I just need to make sure I take care to not disturb it too much?

HoppyDaze

Well-Known Member

Be as careful as you can and wait about a half hour for things to re-settle. That is usually the first thing I do (move the fermenter to where I will be bottling) on bottling night or day

womencantsail

Well-Known Member

Sounds good. I have a feeling there will be a lot of "taking my time" and "being (too) careful" involved with this first batch.

Thanks for your help!

Thanks for your help!

cyberbackpacker

Well-Known Member

DIY dirty diptube/racking arm...

I was bottling a batch Monday night and my cpvc setup was out of commission... so I needed a solution.

Using a number 2 drilled rubber stopper, I cut a 6" piece of siphon tubing (3/8") ran it under hot water to make it malleable, and then pressed it into the drilled stopper... ran it under more hot water to "bend" the tubing so it would curve down. Immediately ran it under cold water once I had my desired shape. Inserted stopper/tubing diptube into the spigot opening, and presto, diptube!

At the end of bottling there was less than 3 ounces of fluid remaining.

I will try and get a pic later to add to this post.

...

I was bottling a batch Monday night and my cpvc setup was out of commission... so I needed a solution.

Using a number 2 drilled rubber stopper, I cut a 6" piece of siphon tubing (3/8") ran it under hot water to make it malleable, and then pressed it into the drilled stopper... ran it under more hot water to "bend" the tubing so it would curve down. Immediately ran it under cold water once I had my desired shape. Inserted stopper/tubing diptube into the spigot opening, and presto, diptube!

At the end of bottling there was less than 3 ounces of fluid remaining.

I will try and get a pic later to add to this post.

...

cyberbackpacker

Well-Known Member

Just thought I would add a few suggestions and an outline of my procedure... bottom line I can bottle a 5g batch including cleaning in 20-30 minutes.

Buy this:

Search Results

Literally it will pay for itself... if you have not used one, I can understand where bottling might suck. I truly believe this is one of the best homebrew pieces of equipment I own.

Also buy this:

NORTHERN BREWER: Sanitation & Cleaning

You can mix up a batch of Starsan and keep it for extended periods of time. No rinse, no fuss, and (relatively) cheap if you don't just mix up 5 gallons all the time and dump. Additionally keep some in a cheap $1 Spray bottle to make it go further too.

Buy the above two pieces to go along with this:

Bottle Filler: Search Results

Everyone has a bottle filler, but I truly believe the vinator and a no rinse sanitizer are just as necessary/mandatory to streamline the process

Combine those three things together along with the other tips in this thread Revvy started (most importantly the bottling bucket diptube/racking arm) and bottling is much easier. I am telling you, the vinator makes sanitizing a snap.

Here is my process:

First, all my bottles are already rinsed/cleaned right after pouring. Time saver #1. On bottling day my bottling bucket is on the counter above the dishwasher with the dishwasher door down, my chair is at the front of the dishwasher door, my bottle tree with vinator on top directly next to the dishwasher on the right hand side, and I line up a case of 20 .5l german flip-top bottles (one case of 20= 2.5 gallons) at a time right next to my chair.

(missing from the pick is bottle tree with vinator on top)

The actual process goes like this: pop the tops on all the bottles. Grab one bottle, sanitize it, and place it under bottle filler; open spigot, start to fill while holding bottle in left hand. With right hand grab new bottle and sanitize. Place sanitized empty bottle on dishwasher door. Start holding bottle being filled with right hand. Once the bottle is filled I remove the filled bottle and immediately using my left hand place the empty sanitized bottle in place and begin filling. I do not lose one drop. While the one is being filled I secure the flip-top onto the filled bottle with my right hand, and place it right back into the case. The process starts over with grabbing an empty bottle, sanitizing, etc... I can bottle a case of 20 bottles in under 6 minutes with ease all by myself. With cleaning figure a total of 20-30 minutes.

I tried kegging, and still might do it for larger batches, but the time for me to transfer from into a keg, and then clean-up was not not significantly faster (2-3 minutes tops).

Just my suggestions, my process, and my way of doing things.... maybe it will help someone out.

PS. I also can do this without flip-tops and that does add about another 5-10 minutes to the process.

...

Buy this:

Search Results

Literally it will pay for itself... if you have not used one, I can understand where bottling might suck. I truly believe this is one of the best homebrew pieces of equipment I own.

Also buy this:

NORTHERN BREWER: Sanitation & Cleaning

You can mix up a batch of Starsan and keep it for extended periods of time. No rinse, no fuss, and (relatively) cheap if you don't just mix up 5 gallons all the time and dump. Additionally keep some in a cheap $1 Spray bottle to make it go further too.

Buy the above two pieces to go along with this:

Bottle Filler: Search Results

Everyone has a bottle filler, but I truly believe the vinator and a no rinse sanitizer are just as necessary/mandatory to streamline the process

Combine those three things together along with the other tips in this thread Revvy started (most importantly the bottling bucket diptube/racking arm) and bottling is much easier. I am telling you, the vinator makes sanitizing a snap.

Here is my process:

First, all my bottles are already rinsed/cleaned right after pouring. Time saver #1. On bottling day my bottling bucket is on the counter above the dishwasher with the dishwasher door down, my chair is at the front of the dishwasher door, my bottle tree with vinator on top directly next to the dishwasher on the right hand side, and I line up a case of 20 .5l german flip-top bottles (one case of 20= 2.5 gallons) at a time right next to my chair.

(missing from the pick is bottle tree with vinator on top)

The actual process goes like this: pop the tops on all the bottles. Grab one bottle, sanitize it, and place it under bottle filler; open spigot, start to fill while holding bottle in left hand. With right hand grab new bottle and sanitize. Place sanitized empty bottle on dishwasher door. Start holding bottle being filled with right hand. Once the bottle is filled I remove the filled bottle and immediately using my left hand place the empty sanitized bottle in place and begin filling. I do not lose one drop. While the one is being filled I secure the flip-top onto the filled bottle with my right hand, and place it right back into the case. The process starts over with grabbing an empty bottle, sanitizing, etc... I can bottle a case of 20 bottles in under 6 minutes with ease all by myself. With cleaning figure a total of 20-30 minutes.

I tried kegging, and still might do it for larger batches, but the time for me to transfer from into a keg, and then clean-up was not not significantly faster (2-3 minutes tops).

Just my suggestions, my process, and my way of doing things.... maybe it will help someone out.

PS. I also can do this without flip-tops and that does add about another 5-10 minutes to the process.

...

beeraroundtown

Well-Known Member

This is all just awesome info. I've been bottling for years and just had a few "why the heck didn't I think of that" moments. I think the most informative part of homebrewing is watching other people brew, man I learn a lot.

I still need a Vinator, but so far a rubber tub of Star San has worked so well. Do you just fill it will Star San solution and just pump it into one bottle at a time? Don't the bottles need some contact time with the Star San or is that quick blast enough?

I still need a Vinator, but so far a rubber tub of Star San has worked so well. Do you just fill it will Star San solution and just pump it into one bottle at a time? Don't the bottles need some contact time with the Star San or is that quick blast enough?

cyberbackpacker

Well-Known Member

Yes, I just fill the Vinator with starsan and you sanitize one bottle at a time; it pumps the bottle with a quick blast which coats all of the interior surface. I also dip the "head" of the bottle into the solution to sanitize the flip-top. I believe recommended contact time is 30 seconds, and I normally am one or two bottles sanitized "ahead" of filling, so contact time is easily met... I have never had any issues.

juvinious

Well-Known Member

.....I was bottling a batch Monday night and my cpvc setup was out of commission.....

Out of commission? How so? I was thinking of putting that cpvc tidbit together after seeing your setup.

CATFISHER74

Well-Known Member

Will the Vinator sit on the counter top or just the tree?

cyberbackpacker

Well-Known Member

Out of commission? How so? I was thinking of putting that cpvc tidbit together after seeing your setup.Originally Posted by cyberbackpacker:

.....I was bottling a batch Monday night and my cpvc setup was out of commission.....

Nothing functional, I just mistakenly used the threaded cpvc part to attach a spigot in one of my fermenters because I could not find the regular nut, so it was not able to be used in the bottling bucket.

cyberbackpacker

Well-Known Member

Will the Vinator sit on the counter top or just the tree?

It will sit on any flat surface... I just have the tree, and if I get extra bottles sanitized I prop them on the bottle tree as I wait to use them. It also is a nice height for me.

juvinious

Well-Known Member

Nothing functional, I just mistakenly used the threaded cpvc part to attach a spigot in one of my fermenters because I could not find the regular nut, so it was not able to be used in the bottling bucket.

Ah ok cool I shall be picking those pieces up to test it out soon.

jeffmeh

Well-Known Member

- Joined

- Feb 26, 2009

- Messages

- 2,145

- Reaction score

- 216

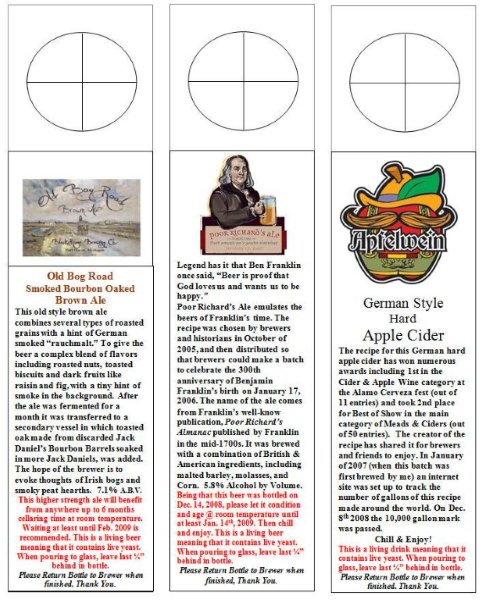

Many thanks to Revvy for the tips and the label template. I poached the template today to make up a few labels to give some bottles away. Actually, I rebuilt it in PowerPoint, because I find that much easier than Word when working with graphics. Unfortunately, I cannot upload it here, but if anyone is interested then let me know.

I don't label unless I'm giving bottles away as gifts, then I don't use traditional labels, I bottle hanging tags. I designed the template and it is freely available online. Thanks to Morotorium

After looking all day for hanging tags templates for bottles, I made up one of my own as a MS word Document.

Each tag is approx 2 inches wide, and the text area after the fold is about 5 inches.

I don't like to glue labels on, especially since I spend so much time removing them (Although some folks swear by milk as label glue). So I like the idea of a hanging tag that slips over the neck of the bottle and hangs there. I printed it out on thick photopaper. All you need to do is cut them out, cut out the hole for the neck (or just make 2 slits at the cross) and fold it downword.

You just basically need to stick a graphic in each space, and add your own text to the text blocks...Or move stuff around and add your own text boxes wherever you want it.

Here's the links from MoRoToRiUm

Sample

Template

When I bottle I just write on the bottlecap with a sharpie a letter code for the name of the beer I brewed. For Example, Old Bog Road (my brown ale) is simply OBR...If I have multiple batches of the same beer going at the same time, I will add a letter code as well.

Again, there are plenty of ways to do just about every aspect of brewing, and the trick is to make it work for you. This is a hobby, not something to do battle with. Even something that some people consider a pain, such as bottling can become as effortless as you choose to make it. All it takes it experimentation; trying something new until it works for you.

I like these. I's probably not do it for every batch, but for certain ones, it lends an air of elegance. Like you say, it's a hobby and things like doing up your own labels can be fun and rewarding and can make your beer appear more professional (or less, as the case may be...) to those who don't understand "homebrew" like we all do.

DrMaddVibe

Well-Known Member

This should be stickied!

PROST!

PROST!

Great idea BrianP seems like an easy way to go on the diptube.

I put the bottling bucket on top of my fridge and hang the filler off the side. I prefer standing and I can rest my hand against the fridge as I fill my bottles.

I put the bottling bucket on top of my fridge and hang the filler off the side. I prefer standing and I can rest my hand against the fridge as I fill my bottles.

metaltim

Well-Known Member

I have one tip for bottlers... buy some kegs.

while kegging i'm sure is easier.. my two best beer drinking buddies have the bakyard pools.. so many of the summers activities are not at my house.. I wouldn't want to hassle with transporting kegs.. bottles are great for that.

Bru

Well-Known Member

I read a bottling tip on the forum somewhere but I can't seem to find it...

It described racking to the bottling bucket the day before bottling to allow for the sediment to settle.

It makes sense but what I need to know is : I assume the carbonating sugar must be added immediately before bottling, if it was added the day before alot of the carbonation would be lost. If its added just before bottling it needs to be stirred which disturbs the sediment making the days wait pointless.

What am I missing ?

Im going to bottling my first AG on Saterday.

It described racking to the bottling bucket the day before bottling to allow for the sediment to settle.

It makes sense but what I need to know is : I assume the carbonating sugar must be added immediately before bottling, if it was added the day before alot of the carbonation would be lost. If its added just before bottling it needs to be stirred which disturbs the sediment making the days wait pointless.

What am I missing ?

Im going to bottling my first AG on Saterday.

I read a bottling tip on the forum somewhere but I can't seem to find it...

It described racking to the bottling bucket the day before bottling to allow for the sediment to settle.

It makes sense but what I need to know is : I assume the carbonating sugar must be added immediately before bottling, if it was added the day before alot of the carbonation would be lost. If its added just before bottling it needs to be stirred which disturbs the sediment making the days wait pointless.

What am I missing ?

Im going to bottling my first AG on Saterday.

That's NOT a good tip, and if it was on this forum it probably was shot down immediately. You open your beer up to both infection and oxydation.

If you are racking off a beer that has spent any length of time in either a long primary or a secondary, then the majority of the sediment HAS ALREADY settled. Anything else, such as the sediment kicked up from lifting your carboy/or bucket onto the table prior to racking will fall back down quickly. And again you are racking off any sediment.

With bottling it is best to begin and finish in one session.

And using tips like the ones in here you should be able to get it done in under an hour.

Bru

Well-Known Member

Great, thanks - and happy birthday

Similar threads

- Replies

- 9

- Views

- 683

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)