Natdavis777

Well-Known Member

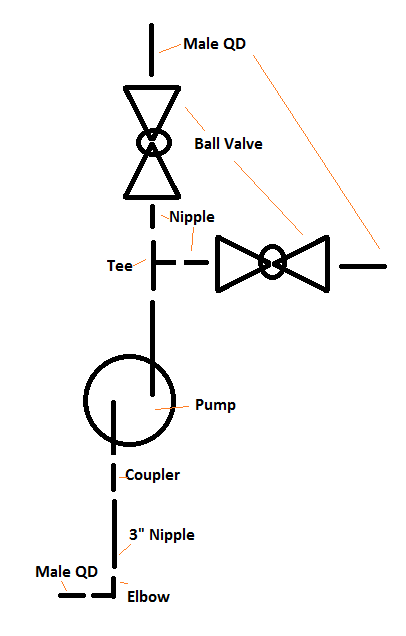

I was having having issues with my pump where I was constantly losing prime (ended up being some grain husks in the impeller) and I got sick and tired of constantly disconnecting/reconnecting hoses to re-establish my prime. I was also running the pump head horizontal which didnt help. With some internet searching, I found sound others pump builds out there and gave it a try. This has helped my pump tremendously. Priming is an ease, Ive yet to have issue since I made this (I also disassemble the pump between uses, even between mashing and cooling) and clean out the entire assembly)