Doed

Belching Dog Brewery

r8rphan: the dimensions for the bag are there, just in millimeters.

485mm = ~19 inches

350mm = ~13.7 inches

700mm = ~ 27.5 inches

485mm = ~19 inches

350mm = ~13.7 inches

700mm = ~ 27.5 inches

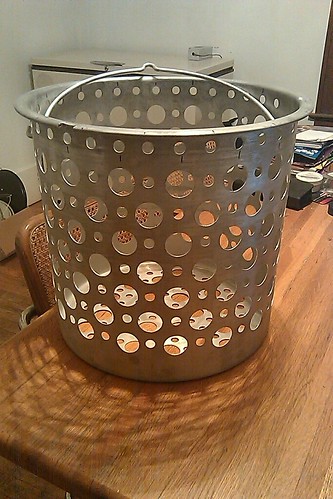

Is the liquid flowing out the bottom and going through the grain bed or is it flowing out the sides near the top?I reckon this basket should flow a bit better now.

after:

Is the liquid flowing out the bottom and going through the grain bed or is it flowing out the sides near the top?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Fair enough. I always have been a tried and true BIABer and have never worried about it before.

Since I am upgrading to a PID electric system I have been watching videos of the "3 vessel" systems and I was wondering if it would be possible to use the grain bed to filter like they do.

Where did you get the pot and basket?

thughes said:It's that 62qt Bayou Classic aluminum pot I told you I scored for $50.00 on Amazon. :rockin:

Todd,

Questions/Comments about your chassis:

1. are your element and pump hard-wired? I don't see any outlets/connectors on the back of your box. Or . . . did you run short lengths of wire out the rear to female connectors for your element and pump?

3. Since you're familiar with the tolerances inside your box, do you think it would work to mount the SSR/Heat Sink on the top where you have your EPO, then fit the EPO in the upper right corner of the front panel?

4. Moving the SSR/Heat Sink from the rear would allow room back there for the connectors for Power IN, Element, Pump, Temp Probe.

5. Otherwise, do you think there is room on the top for both the heat sink and the EPO?

6. How necessary do you think the EPO is on a simple single-vessel BIAB controller is - especially if you have GFCI protection as well as internal fusing? I can understand the need when one is dealing with 3 vessels (2 of which have elements), 2-3 pumps, and various other electric valves and solenoids.

They are not hard-wired, I ran dongles out of the rear and terminated them with the appropriate plugs (240/30 and 120/15). Installing outlets in the rear panel and moving the SSR/heatsink to the top seems as though it would make things too crowded for my liking (inside the box).

If something goes horribly wrong causing sparks or flames to start shooting out of my rig, I don't have to think about what to do. I (or somebody in the near vicinity) can simply react by punching the EPO. I like the feeling of safety that gives me.

Dongles are 18" long. (more than long enough for the girls I brew with)

Having the panic button on the top makes it an easy target but mounting on the front would work too (probably better, as I have accidentally bumped it on more than one occasion).

Push buttons are easy to operate and rubber feet on the bottom of the control box keep it from sliding around.

Isn't it about time you stopped researching and started building? :cross:

I just wanted to chime in and say "THANKS" to gunner65 & P-J for not only this thread but the many others I have read to gather more information and understanding. HBT forums :rockin: on many subjects. I lurk alot and learn. Cheers

I would like to say I appreciate that but I am no inventor I just followed the footsteps of many great thinkers here. If I were going to lay out my list of folks to thank it would be Scuba_Steve, The Pol, and Bobby_M they were the most influential in my design. So I was walking through harbour freight when I was contemplating my brew stand and found the cart thats about all the originality I bring to this. I amy have been one of the first to complete a single vessel all electric but that is because most designs were far more complex than mine and original to so I can take no credit for any of that.