Weezy

Well-Known Member

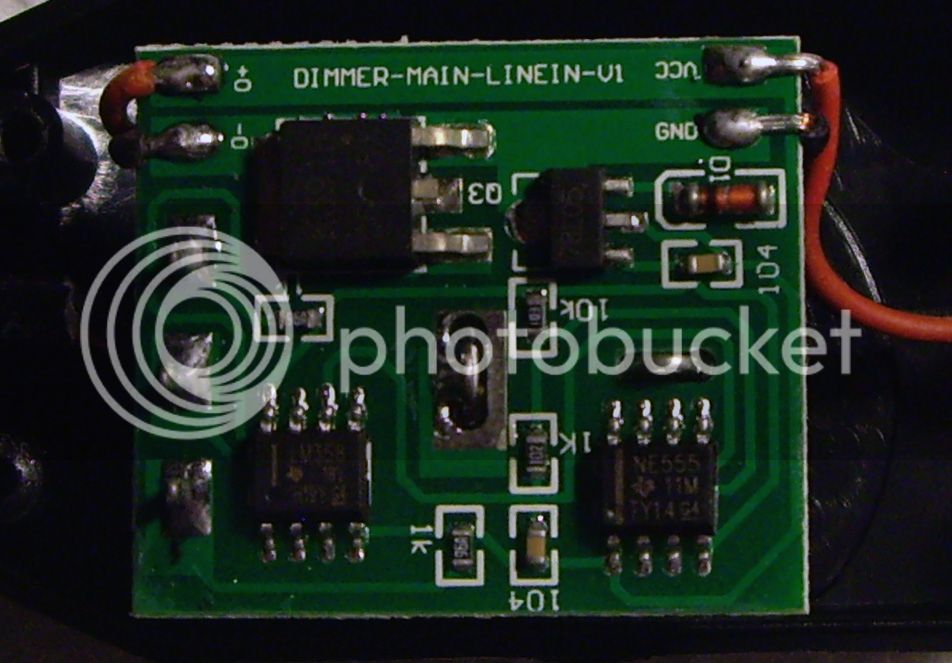

The beauty of 12V pumps is being able to use the PWM controller to vary flow rate. With a PWM you don't even need an on/off switch. Much better solution than a valve.

Ok I got the little tan pump and after one use I made a alteration. I made it so I can in screw the pump and leave the front part on my ball valve. It needed clean twice but that's because it was a pumpkin ale. But great little cheap pump!!!

Sent from my iPhone using Home Brew

The beauty of 12V pumps is being able to use the PWM controller to vary flow rate. With a PWM you don't even need an on/off switch. Much better solution than a valve.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

I understand what your saying but with these 12v style pumps many people here have had the pumps fail and seize up by restricting the flow. the pwm controller seems to be less stressfull on the pump motorThe beauty of centrifugal pumps is that you can vary the flow by simply throttling the outlet side. They are not positive displacement pumps, and as you throttle the flow, the power required goes down, not up as it would with a positive displacement pump......... There really is no reason to use a PWM controller............ a valve works just as well and is a lot simpler.

H.W.

I connect my pumps the same exact way... I use cheap shallow cake pans under where each pump connects to catch the little bit of spillage when disconnecting and moving the pumps about. works ok but I would still like to improve on it a bit.Yea, I use a female camlock disconnect screwed on the inlet portion of my pump so I can connect directly to the bottom drain valve on my kettle, then I use a male camlock from my valves and can close the valve and move the pump to whatever vessel I need to transfer from...makes it very portable.

You can kind of tell what I mean in this pic...

View attachment 221800