mobrewdude

Well-Known Member

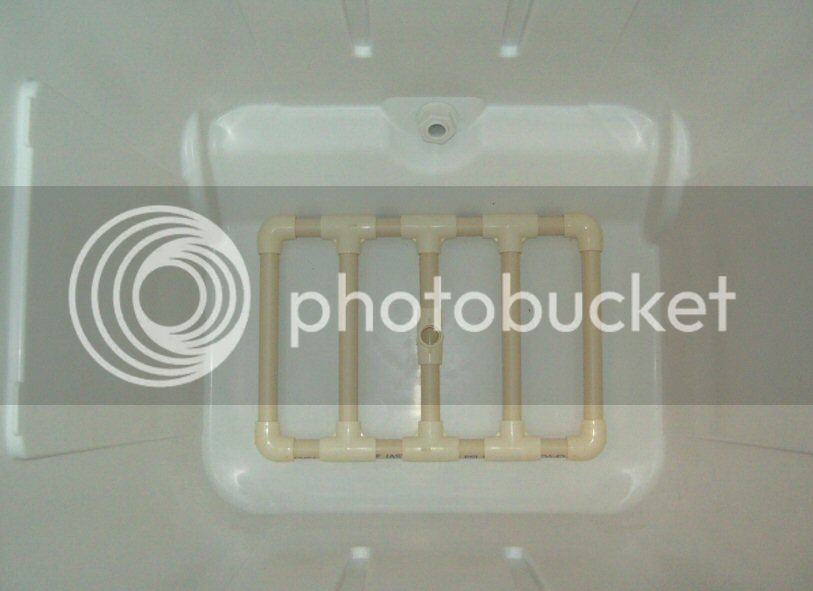

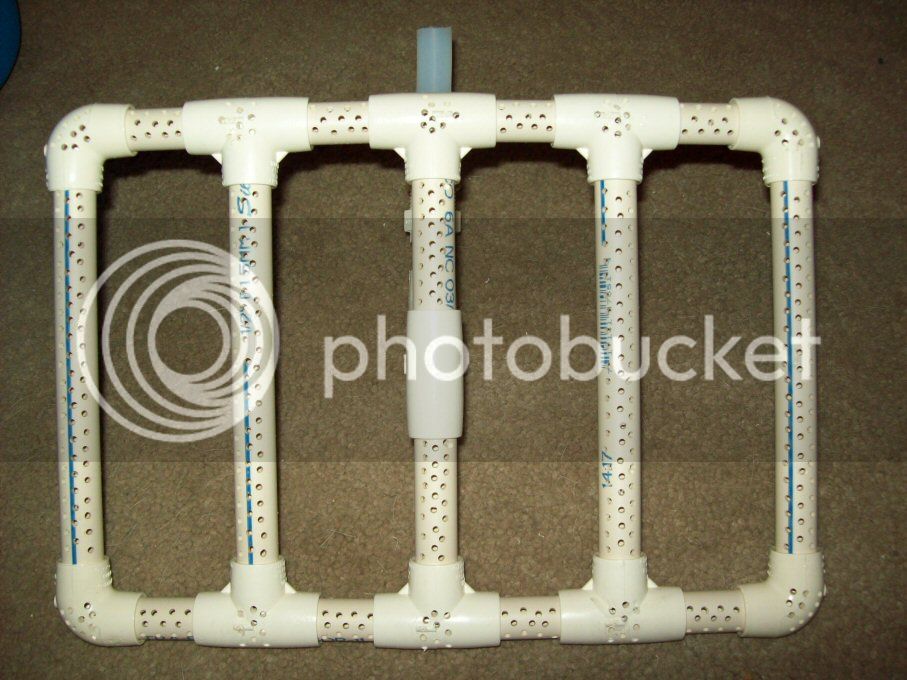

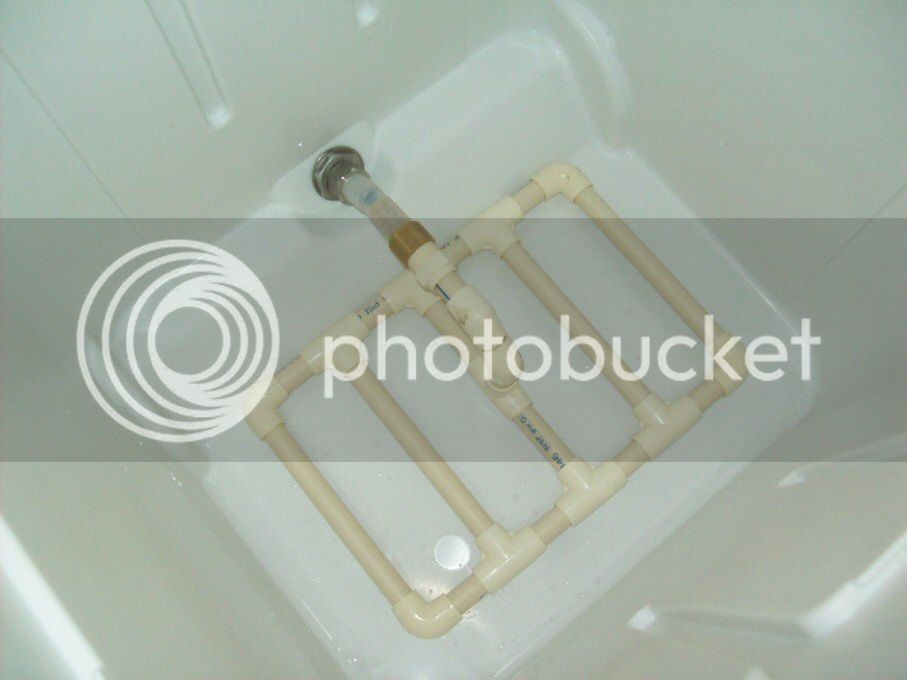

I'm in the process of making the jump to all grain. I purchased a 60 qt Igloo "Ice Cube" cooler for my MLT conversion and plan to fly sparge. Below is a pic of my initial design for the manifold (minus the slots or holes in the bottom of the tubing). Ultimately, I will have a stainless valve which will be connected to the hole you can see in the center of the manifold. I'm looking for any critique/improvement that can be completed with CPVC.

Thanks in advance!

Thanks in advance!