Stevorino

Well-Known Member

I'm already making some purchases for my All Grain Equipment-- I appreciate the help so far, you guys!

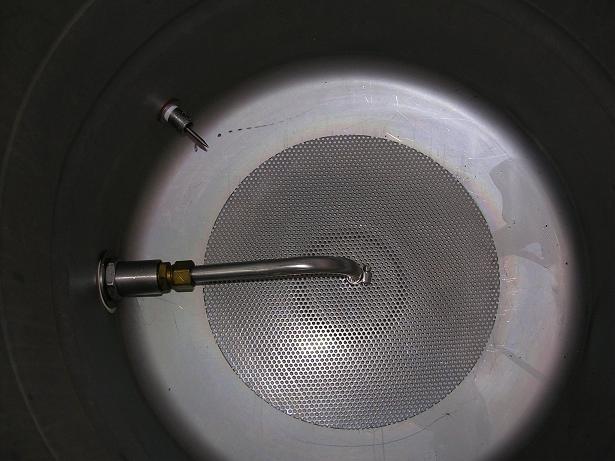

The last thing I'm deciding is between a Cooler MLT or Keggle MLT. However, I don't quite understand how to make a Keggle MLT....I'm assuming w/ a Stainless Steel False Bottom? Any pictures and/or explanations would be amazing.

Thanks again guys!

The last thing I'm deciding is between a Cooler MLT or Keggle MLT. However, I don't quite understand how to make a Keggle MLT....I'm assuming w/ a Stainless Steel False Bottom? Any pictures and/or explanations would be amazing.

Thanks again guys!