- Joined

- Feb 10, 2016

- Messages

- 107

- Reaction score

- 79

Hello everyone!

I was intrigued a few years back by a thread in which someone used an Anova Sous Vide Precision Cooker as a pseudo-RIMS for mash control; the idea was to use a chinois or hop strainer to create a grain-free zone in the mash tun, in which the cooker was placed. Some noted that this probably created a local hot spot, though perhaps by separately recirculating the wort through a false bottom, this could be fixed.

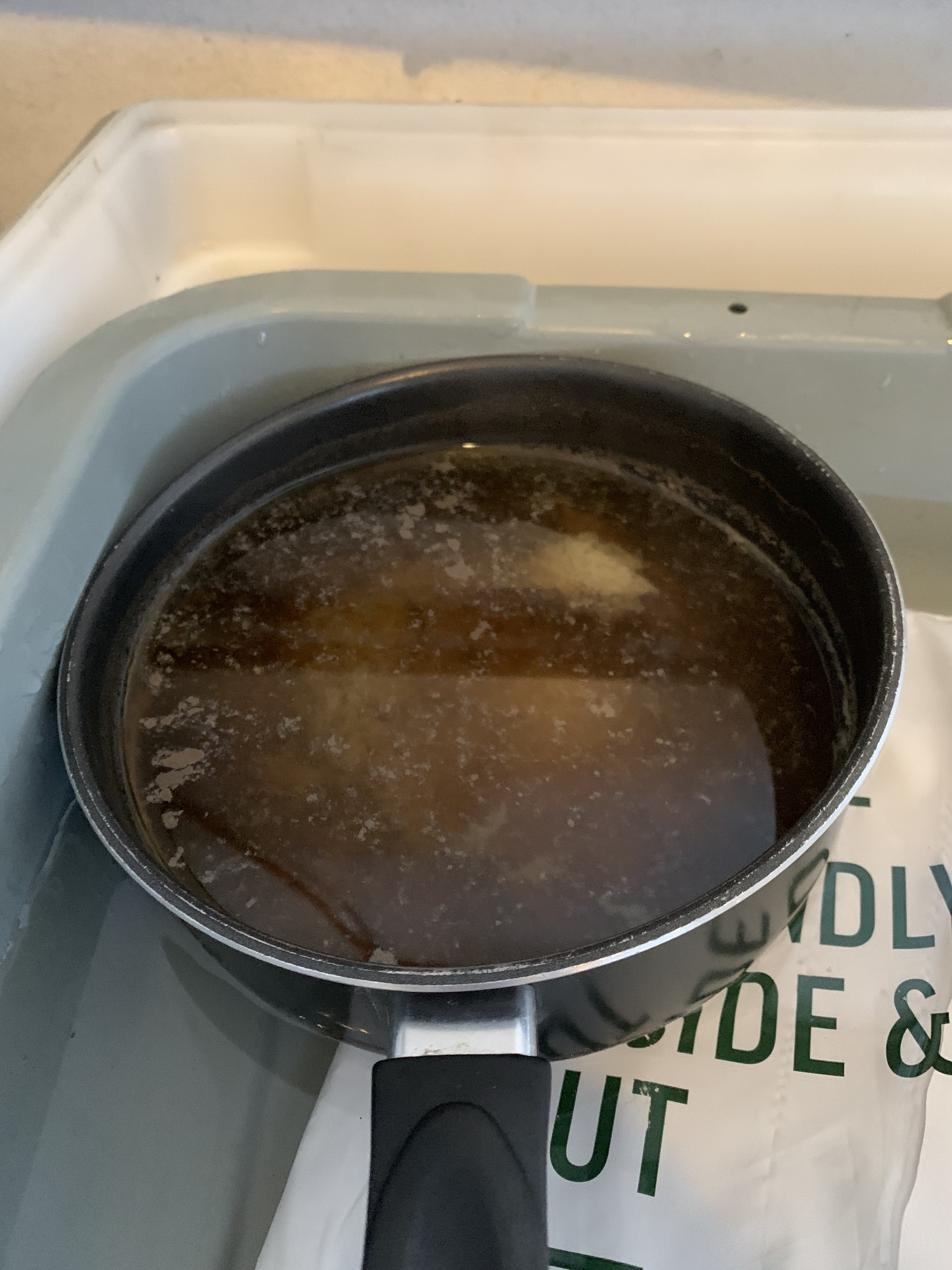

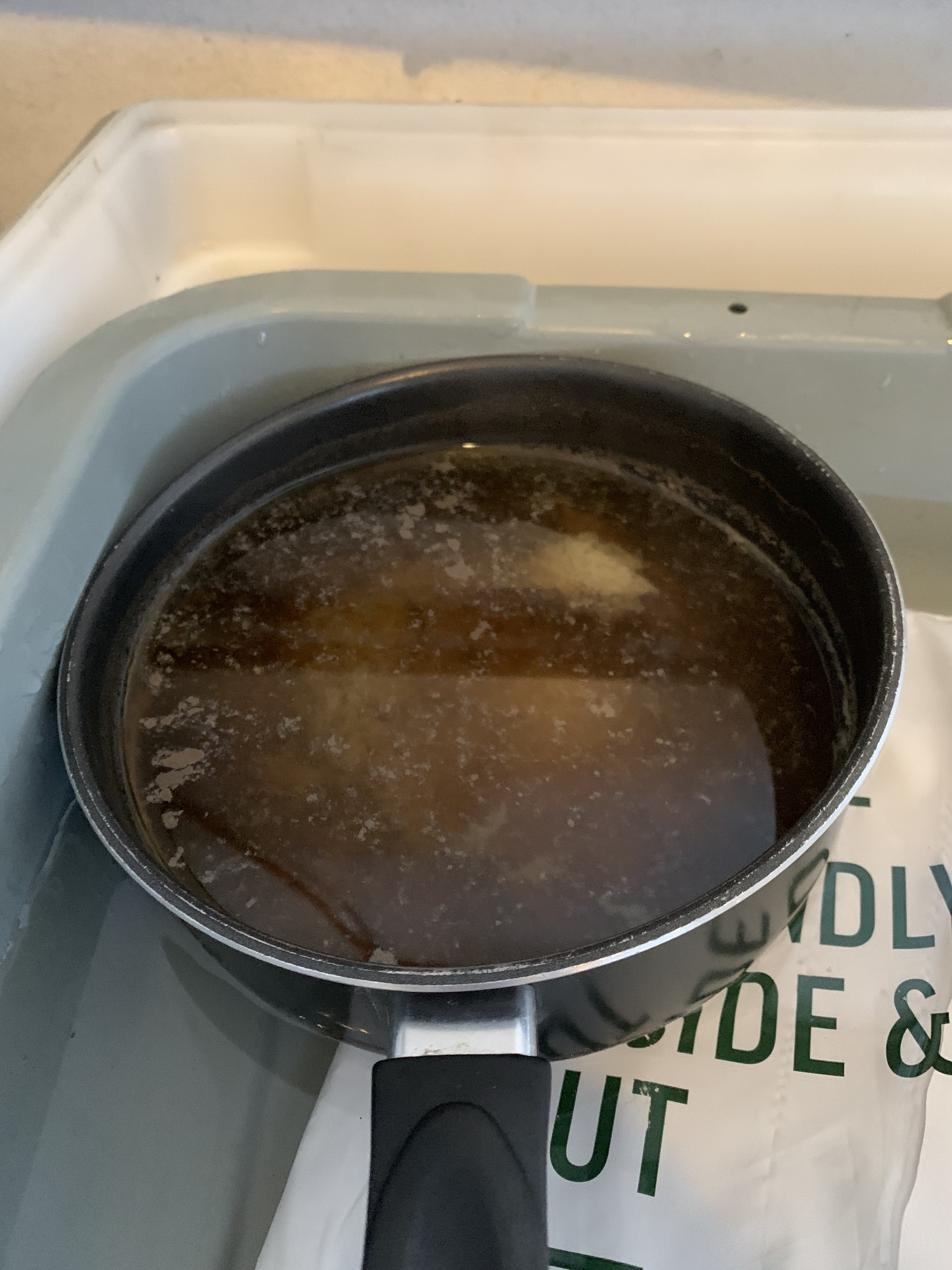

In any case, the idea struck me, and since my normal gear is out of commission while I convert it into an all-electric setup, I decided to have some fun and brew a quart of beer. Specifically, two beers: a Dark Mild and a Helles Lager (fermented with White Labs' High Pressure Lager yeast in a 1L PET bottle with a Spunding Valve).

Here are pictures of the process, and some observations:

And that's about it! If anyone has any questions, I'd be happy to answer them

Cheers!

I was intrigued a few years back by a thread in which someone used an Anova Sous Vide Precision Cooker as a pseudo-RIMS for mash control; the idea was to use a chinois or hop strainer to create a grain-free zone in the mash tun, in which the cooker was placed. Some noted that this probably created a local hot spot, though perhaps by separately recirculating the wort through a false bottom, this could be fixed.

In any case, the idea struck me, and since my normal gear is out of commission while I convert it into an all-electric setup, I decided to have some fun and brew a quart of beer. Specifically, two beers: a Dark Mild and a Helles Lager (fermented with White Labs' High Pressure Lager yeast in a 1L PET bottle with a Spunding Valve).

Here are pictures of the process, and some observations:

- Instead of proper Sous Vide vacuum bags, use Ziploc gallon bags; they're easier to seal, which avoids the air pocket problem I ran into when trying to seal the vacuum bags while full of liquid. I used two bags in order to avoid leaks (in and of themselves unlikely)

- When mashing in, it's easiest to secure the Ziploc to the inside of a 1 gallon bucket and use that as a "manifold" in which to add first the water, then the malt

- Side note: I didn't add any salts, but you could easily get accurate enough measurements with a .01g scale, available for $15 and a good thing to have if you wish to brew 1 gallon batches

- The Sous Vide held mash temps, presumably, very well, but I had efficiency issues with the Helles Lager, for which I employed step mashes of ~122˚, 148˚, and 156˚ (something like that), which may have resulted from simply too little time allowed for the mash temp to ramp up (some 30 minutes per step once the water bath was at temp)

- Boiling is easy and straightforward; have some bottled water on hand for topping up

- Chilling is fast enough in an ice water bath

- When pitching yeast, it may be wise to transfer your slurry to a cylindrical flask in order to dole out, say, 10 Billion cells (10% of a super fresh pack), or simply pitch dry yeast to arbitrary accuracy

- You'll obviously have to rig up your own fermenter; I used a PET bottle with a Ball Lock adapter and Spunding Valve, and a plastic 1 qt pail, and both seem to be working well

And that's about it! If anyone has any questions, I'd be happy to answer them

Cheers!