frodus17

Well-Known Member

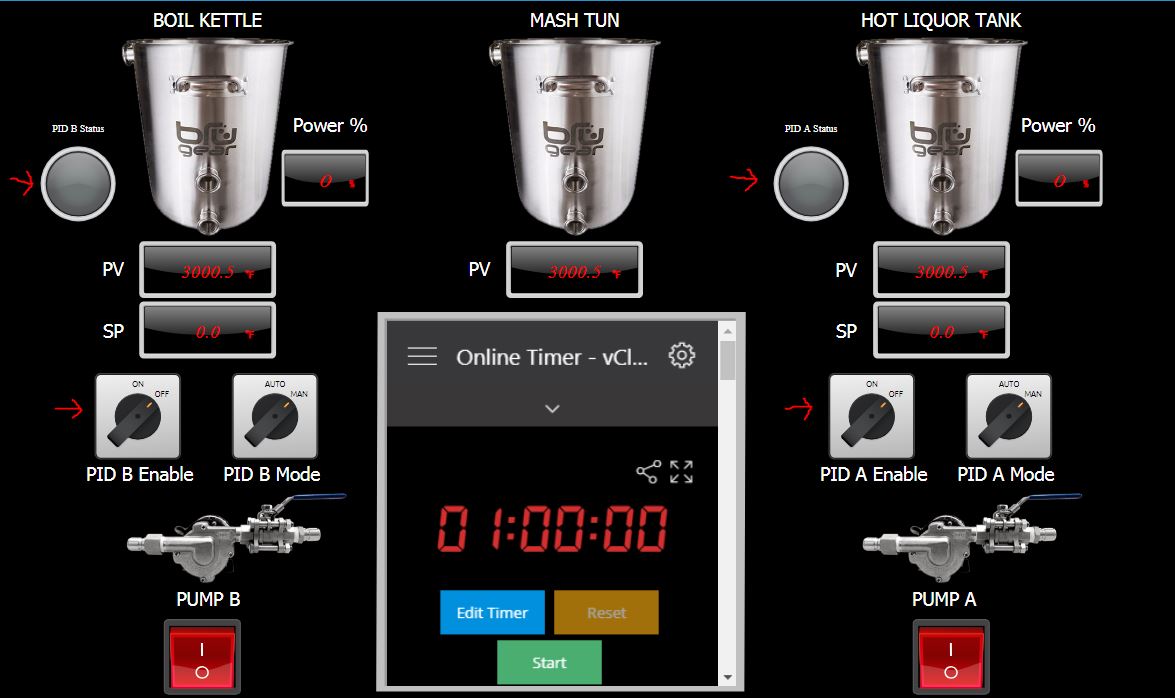

Everything is wired up, powered up and I've started testing. The Temp sensors are all working and power and connections to everything look good. I can connect to my wifi network and control throughout the house (and remotely to preheat my HLT for brew day after work, HAHA). The Pumps are run off of one of the alarm outputs of the PID controllers and turn the SSR on/off accordingly. I found a nice little start/stop/reset timer and embedded into my dashboard. I can add functionality to my control panel later as they are needed. I still have 1 Temp sensor input, 4 digital inputs and 6 3A relay outputs I can use.

So now I just need to wire the heating elements and run the Autotune on the BK and HLT PID controllers and I think I can start brewing again. Also need to mount the 2 pumps and control panel to my brew stand.

Here's the control panel HMI as it is, Simple and easy to manage:

So now I just need to wire the heating elements and run the Autotune on the BK and HLT PID controllers and I think I can start brewing again. Also need to mount the 2 pumps and control panel to my brew stand.

Here's the control panel HMI as it is, Simple and easy to manage: