homebrewdude76

Well-Known Member

What I thought I could do, and what it actually can do might not be the same.

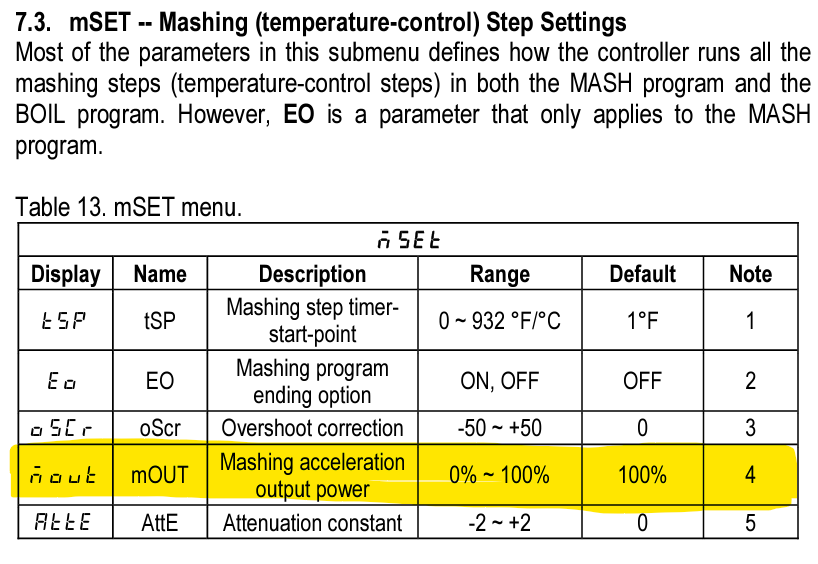

Would like to have programed the mash steps to also include output power. But looks like I can't do that.

I wonder if when I am in "HOLD" mode on the program,

mPRG m1S 165.

m1t SKIP Skip step to sync alarm

m2S 165

m2t HOLD Raise temp to 165 then sound alarm to put in grain ( I want this at Max output, it is just water)

m3S 153

m3t 1:00 Hold at 153 for 1 hour ( I want this at reduced output to avoid scorching)

m4S 153

m4t 0:15 Raise temp to 172 for 15 min ( I want this at reduced output to avoid scorching)

m5S 172

m5t hold

m6S 172

m6t END

Would like to have programed the mash steps to also include output power. But looks like I can't do that.

I wonder if when I am in "HOLD" mode on the program,

mPRG m1S 165.

m1t SKIP Skip step to sync alarm

m2S 165

m2t HOLD Raise temp to 165 then sound alarm to put in grain ( I want this at Max output, it is just water)

m3S 153

m3t 1:00 Hold at 153 for 1 hour ( I want this at reduced output to avoid scorching)

m4S 153

m4t 0:15 Raise temp to 172 for 15 min ( I want this at reduced output to avoid scorching)

m5S 172

m5t hold

m6S 172

m6t END