@mcar1919

It's kinda difficult to drill through thin stainless without distorting/twisting it. It can be done though, with the right touch. I don't think the holes make much difference anyway, as they will still be too small for much grain to move through. For comparison, look at one of those real 40" stainless mash paddles, the holes are at least 1/2" or 3/4".

I have used one of those large ones and they're a charm to stir with, even in my 8 gallon kettle, but very long and fairly heavy. I've used wooden stir paddles too, the solid ones used in commercial kitchens, they work fine and are a lot gentler on the stainless kettle sides and bottom.

When mashing in the kettle, I use induction, so a medium setting 1200-1800W and constant stirring works well. Then turn it off, put the lid on and cover with a thick folded over towel to insulate. A few days ago I brewed a Mild, mashing at 161F (!), which was difficult to keep steady at that temp, even with insulation wrapped around the kettle.

Sad to say, I think I discovered a shortcoming on my venerable $16 CDN thermometer... it doesn't seem to react fast, jumping up and down by 3-4 degrees increments. Very strange! Maybe one of those (overpriced) $80 Thermapens needs to be actually considered now.

After the mashout, I use a gallon cooking pot with a handle to ladle the mash into the mash tun. A bit drippy and messy, but gets the job done, The last gallon or so I just dump in straight from the kettle.

I've tried boiling water infusions in the cooler, but the open tun loses a lot of heat while stirring in the addition, sometimes it drops down lower than you started at, then you start chasing your tail. I guess it could work with some practice, risking overshooting rather than under, which is the pits.

Milling

Maybe some LHBS clerk was telling fables to justify their lousy mill setting.

If you want to convert and extract the goodness from wheat (or rye, triticale, buckwheat, ah, millet, now that's a challenge) it needs to be cracked, whole kernels don't mash (convert) well. Hence the narrower gap.

Milling twice maybe better than once, but is no match for a correctly adjusted gap to match the kernels to be crushed. I had a wheat beer from someone and was wondering: "where's the wheat?" As it turned out, their grist milled at the LHBS had at least half of the wheat kernels still intact, uncrushed. They had fallen straight through.

When I do a step mash, incorporating a beta-glucanase/protein rest around 121-125F for 15-20 minutes when using large percentages of (unmalted) flaked goods and/or wheat or rye malt, I usually don't need rice hulls to lauter. If it turns out too slow I stir in a few hand fulls of rice hulls and that fixes it. Stirring them in later is a bit of a pain as they don't hydrate very well, and tend to float.

Toward the end of the mash most enzymes are in the liquid phase (wort), so heating up the thin part of the mash, mostly wort and some grain, to mashout temps will denature them. Not sure if the thin stage with some grist left in it can be safely boiled (concern about pH and tannin extraction). Then dumping that back into the tun will raise the temps and if you heated up enough, total mashout has been accomplished.

Decoctions are the opposite. You take the

thick part (mostly grist), and run it through the various mash rests, especially a 20-30' sacch rest to convert. Then you heat up slowly to boiling temps and boil for 10-15' to create melanoidins, the flavor. By adding that hot mix back to the tun, which has been resting/mashing at a certain temperature, it will raise its temps to the next mash temp, stage, or rest. Then do it again (double), and again (triple decoction).

Decoctions are fun and often rewarding, making it worth the effort and time if you're after the ultimate malt profile. I did double wheat decoction for a while, but the 3.5 hour mash process got old pretty fast. However, the result was noticeably beyond subtle, and perhaps second to none for those who appreciate it.

I always preheat the tun by adding strike water 7-10°F over calculated. After 5 minutes it's pretty close to where it should be. If still a little too hot it's easy to add a few cups of cold water. If too cold... <ugh>. It's all wet finger science.

Automation can be great, and where to use it, is very personal. I think the mash control is important, but also means more equipment to hook up and clean.

Now go brew a batch of beer with your new mash tun and let us know what you think.

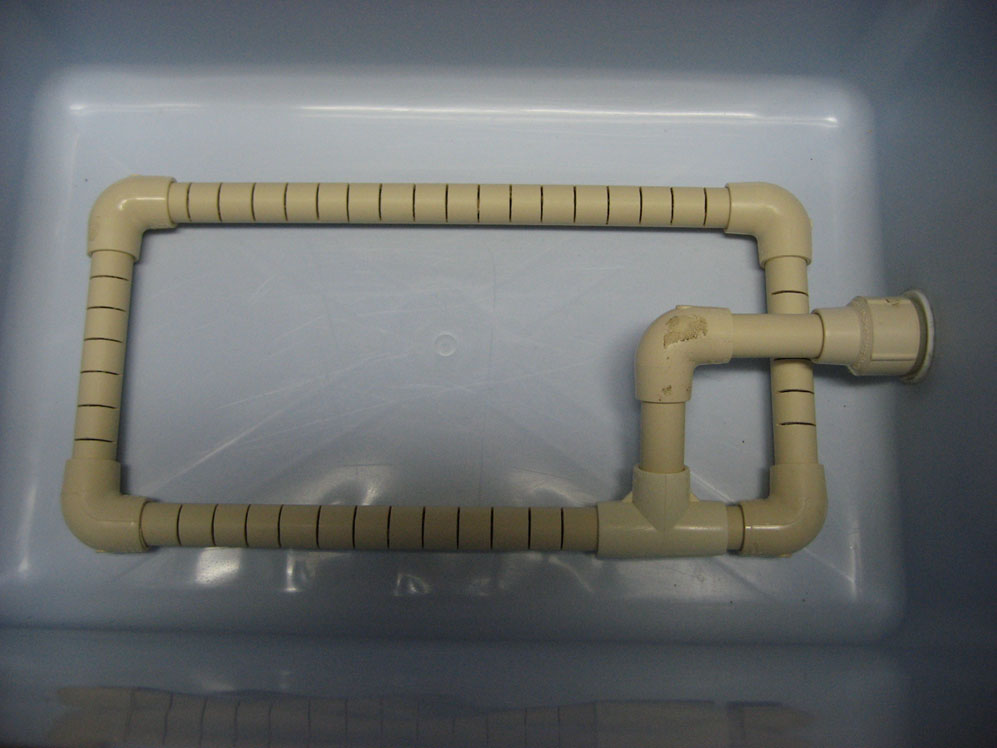

P.S. Did you mean to say you're going to use a (Wilser) voile bag inside your mash tun on top of the manifold?