peterpasha

Member

- Joined

- May 13, 2017

- Messages

- 6

- Reaction score

- 2

Backstory: I have been fermenting lagers in a ball-lock keg in my small old keezer. It's just big enough for one keg and a growler for the blowoff tube. I'm using a blowoff tube connected a disconnect on the gas-in post in which I have removed the poppet cause I didn't want any kreusen gunking up the post. I've done a couple of lagers like this with a little sucess, it hasn't been brilliant, but it hasn't been a disaster until now. I haven't had the best success with transferring under pressure, so I've been using an auto-siphon to transfer from the fermenting keg to a secondary keg for the longer lagering. The previous brew before this one, I had a brain-fart senior's moment, and pulled the disconnect without venting the fermentation co2 from the keg. Needless to say, there was a magnificent geyser of beer!

Current situation: About 2 weeks ago, I decided to transfer the beer from the primary keg to the secondary keg, it had been in the primary for over 2 weeks and I wanted to get set up for another lager brewday. I pulled the pressure relief pin and heard a lot of gas venting from the keg. After about 45 seconds of this, I started to get foam through the pressure relief and I stopped venting. I figured that venting had caused the gas to come out of suspension in the beer and had produced a large head in the keg. So I figured no harm, no foul, I'll put it back in the keezer for another week until the head can reduce, figuring the cold lagering temperature would help. The keezer is set to 40F for lagering. But after a week, I still had an incredible amount of foam coming through the vent.

I gave it another week at 40F and tried again, same result. Now I figured that I had no way to relieve the still-considerable pressure inside the keg, so I might as well try to transfer it under pressure to a secondary keg using the naturally occurring co2 as a propellant.

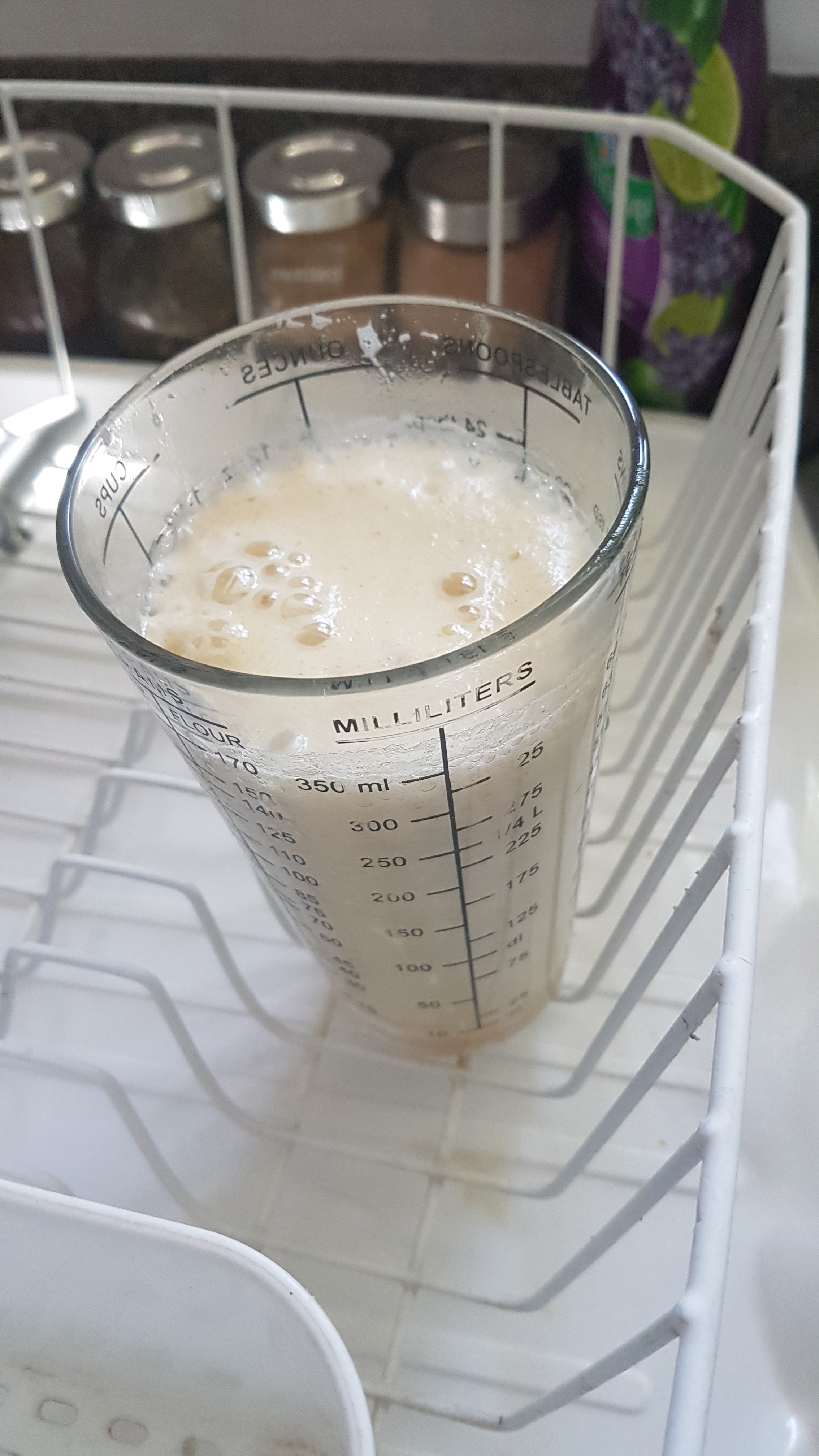

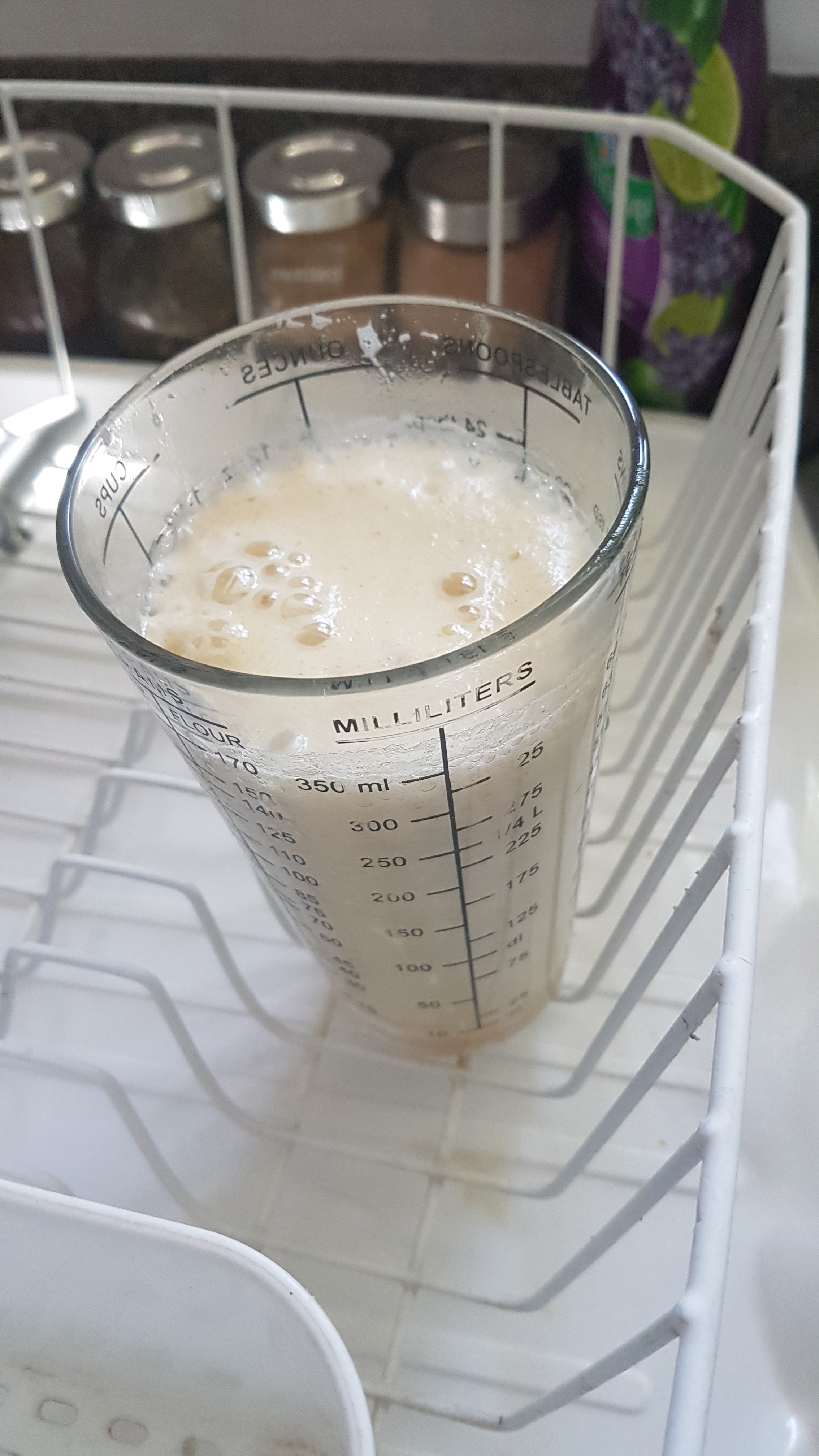

But all I got was foam. I could see nothing but foam in the transfer tubing, so after about 5 minutes I stopped that and put a picnic tap on a beer line and pulled a glass. Foam.

I don't know what else to do other than transfer this to an open bucket and wait for the foam to dissipate before transferring it to a secondary keg for longer lager, but by then the exposure to oxygen will be fatal.

Recipe:

Title: American Pils

Author: Wharf Works

Brew Method: All Grain

Style Name: Classic American Pilsner

Boil Time: 60 min

Batch Size: 5 gallons (fermentor volume)

Boil Size: 6 gallons

Boil Gravity: 1.045

Efficiency: 50% (brew house)

STATS:

Original Gravity: 1.054

Final Gravity: 1.009

ABV (standard): 5.93%

IBU (tinseth): 35.08

SRM (morey): 10.43

Mash pH: 5.53

FERMENTABLES:

10 lb - Pilsner (66.7%)

2 lb - Pale 2-Row (13.3%)

2 lb - Carapils (Dextrine Malt) (13.3%)

1 lb - Munich - 60L (6.7%)

HOPS:

0.5 oz - Magnum, Type: Pellet, AA: 15, Use: Boil for 60 min, IBU: 29.75

0.5 oz - Saaz, Type: Pellet, AA: 3.5, Use: Boil for 30 min, IBU: 5.33

MASH GUIDELINES:

1) Temperature, Temp: 152 F, Time: 60 min, Amount: 18.75 qt

2) Temperature, Temp: 170 F, Time: 20 min, lauter

3) Sparge, Temp: 170 F, Time: 20 min, Amount: 12 qt

Starting Mash Thickness: 1.25 qt/lb

YEAST:

Fermentis / Safale - Saflager - German Lager Yeast S-23

Anyone experienced anything like this?

Current situation: About 2 weeks ago, I decided to transfer the beer from the primary keg to the secondary keg, it had been in the primary for over 2 weeks and I wanted to get set up for another lager brewday. I pulled the pressure relief pin and heard a lot of gas venting from the keg. After about 45 seconds of this, I started to get foam through the pressure relief and I stopped venting. I figured that venting had caused the gas to come out of suspension in the beer and had produced a large head in the keg. So I figured no harm, no foul, I'll put it back in the keezer for another week until the head can reduce, figuring the cold lagering temperature would help. The keezer is set to 40F for lagering. But after a week, I still had an incredible amount of foam coming through the vent.

I gave it another week at 40F and tried again, same result. Now I figured that I had no way to relieve the still-considerable pressure inside the keg, so I might as well try to transfer it under pressure to a secondary keg using the naturally occurring co2 as a propellant.

But all I got was foam. I could see nothing but foam in the transfer tubing, so after about 5 minutes I stopped that and put a picnic tap on a beer line and pulled a glass. Foam.

I don't know what else to do other than transfer this to an open bucket and wait for the foam to dissipate before transferring it to a secondary keg for longer lager, but by then the exposure to oxygen will be fatal.

Recipe:

Title: American Pils

Author: Wharf Works

Brew Method: All Grain

Style Name: Classic American Pilsner

Boil Time: 60 min

Batch Size: 5 gallons (fermentor volume)

Boil Size: 6 gallons

Boil Gravity: 1.045

Efficiency: 50% (brew house)

STATS:

Original Gravity: 1.054

Final Gravity: 1.009

ABV (standard): 5.93%

IBU (tinseth): 35.08

SRM (morey): 10.43

Mash pH: 5.53

FERMENTABLES:

10 lb - Pilsner (66.7%)

2 lb - Pale 2-Row (13.3%)

2 lb - Carapils (Dextrine Malt) (13.3%)

1 lb - Munich - 60L (6.7%)

HOPS:

0.5 oz - Magnum, Type: Pellet, AA: 15, Use: Boil for 60 min, IBU: 29.75

0.5 oz - Saaz, Type: Pellet, AA: 3.5, Use: Boil for 30 min, IBU: 5.33

MASH GUIDELINES:

1) Temperature, Temp: 152 F, Time: 60 min, Amount: 18.75 qt

2) Temperature, Temp: 170 F, Time: 20 min, lauter

3) Sparge, Temp: 170 F, Time: 20 min, Amount: 12 qt

Starting Mash Thickness: 1.25 qt/lb

YEAST:

Fermentis / Safale - Saflager - German Lager Yeast S-23

Anyone experienced anything like this?